Weakly alkaline smokeless tin spraying soldering flux and preparation method thereof

A weak alkaline and flux technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve environmental pollution and other problems, achieve high safety, avoid pollution, and improve the effect of soldering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

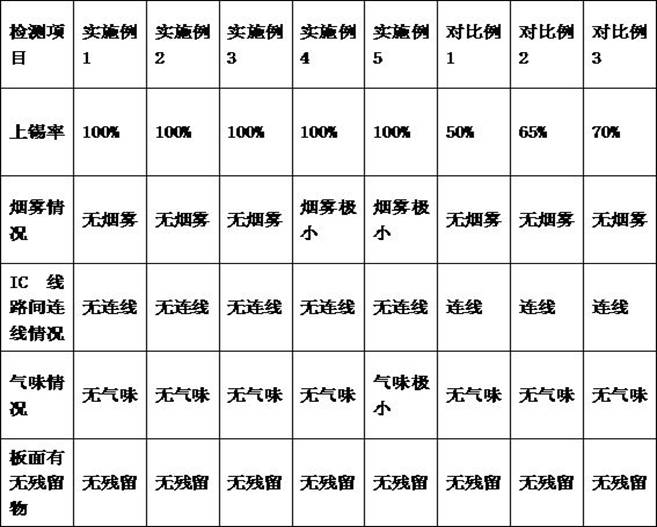

Examples

Embodiment 1

[0020] A preparation method of a tin-spraying flux, comprising the following steps: weighing the following raw materials by weight: 5% of choline, 1% of biquinol, 0.5% of tetraethylamine perfluorooctanesulfonate, Tetrahydrofurfuryl alcohol 10%, benzotriazole 0.3%, polyethylene glycol monomethyl ether 250 15%, polyethylene glycol 20%, deionized water 48.2%; deionized water, choline, perfluorooctyl The sulfonic acid tetraethylamine was added to the reaction kettle in turn and stirred. After it was completely dissolved, tetrahydrofurfuryl alcohol, polyethylene glycol, polyethylene glycol monomethyl ether 250, benzotriazole and biquinol were added and stirred. After 1.5 hours, the raw materials were fully mixed and dissolved, and the mixture was allowed to stand for 30 minutes, and then the tin-spraying flux was obtained by filtration.

Embodiment 2

[0022] A preparation method of tin-spraying flux, comprising the following steps: weighing the following raw materials by weight: 4% of choline, 1% of biquinol, 0.5% of tetraethylamine perfluorooctanesulfonate, Divalent ester (DBE) 15%, benzotriazole 0.3%, polyethylene glycol monomethyl ether 250 10%, polyethylene glycol 30%, deionized water 39.2%; deionized water, choline, Tetraethylamine perfluorooctane sulfonate was added to the reaction kettle in turn and stirred. After it was completely dissolved, dibasic acid ester (DBE), polyethylene glycol, polyethylene glycol monomethyl ether 250, and benzotrioxide were added in turn. The azole and biquinol were stirred for 1.5 hours to fully mix and dissolve the raw materials, let stand for 30 minutes, and filtered to obtain the tin-spraying flux.

Embodiment 3

[0024] A preparation method of tin-spraying flux, comprising the following steps: weighing the following raw materials by weight: 6% of choline, 1.5% of biquinol, 1.5% of tetraethylamine perfluorooctanesulfonate, Glycerol 10%, ethylene glycol 5%, benzotriazole 0.5%, polyethylene glycol monomethyl ether 250 20%, polyethylene glycol 20%, deionized water 41.5%; Alkali and tetraethylamine perfluorooctanesulfonate were added to the reaction kettle in turn and stirred. After being completely dissolved, glycerol, polyethylene glycol, polyethylene glycol monomethyl ether 250, and benzotriazole were added in turn. , Stir biquinol for 1.5 hours to fully mix and dissolve the raw materials, let stand for 30 minutes, and filter to obtain tin-spraying flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com