Preparation method and application of poplar transformed product for improving enteritis

A conversion product, poplar technology, which is applied in the field of poplar conversion product preparation, can solve problems such as the lack of core technology for deep processing, and achieve the effect of cheap raw material sources, abundant raw material sources, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

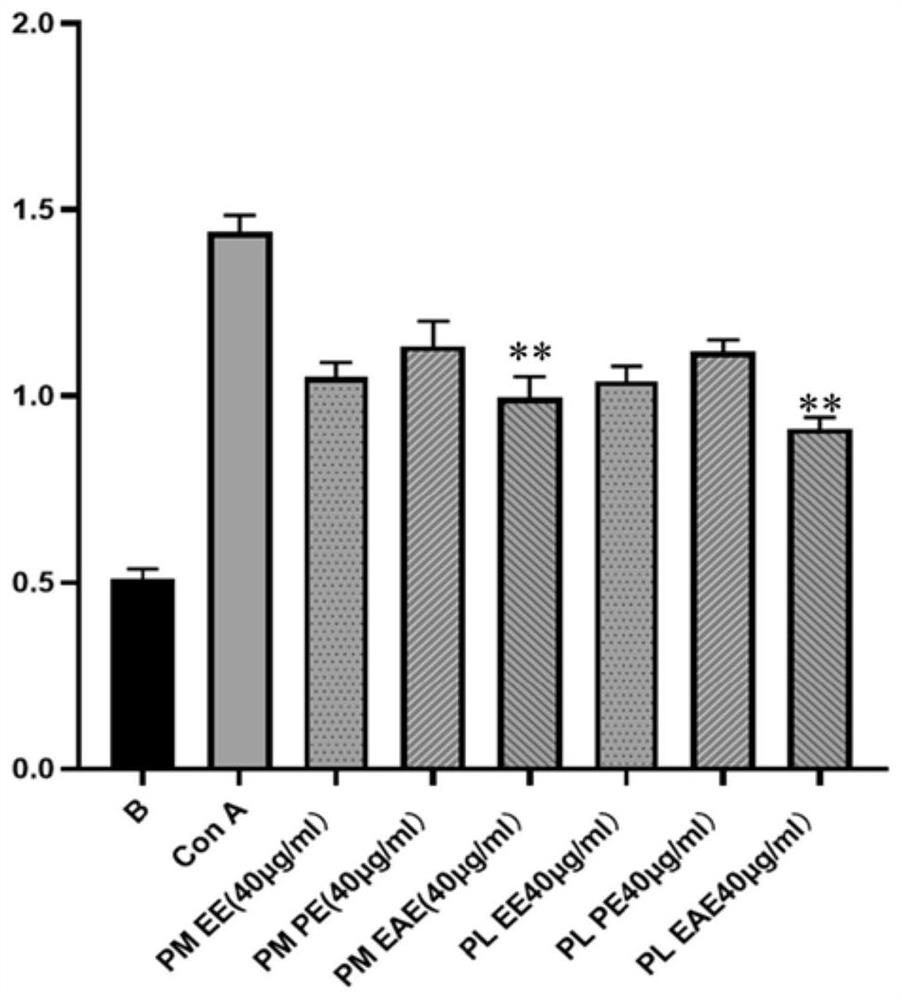

[0033] (1) Using poplar processing waste poplar sawdust (PM) and poplar leaves (PL) as raw materials, drying the poplar sawdust and poplar leaves at 60° C. for 8 hours, pulverizing them through a 200-mesh sieve respectively, and collecting poplar sawdust powder and poplar leaves pink;

[0034] (2) Using 90% ethanol solution as a solvent, the poplar sawdust powder and poplar leaf powder were extracted under heat reflux at 60°C, the ratio of solid to liquid was 1:5, the extraction time was 2.5h, and the extraction was performed 3 times, followed by suction filtration and decompression. Evaporation to obtain an extract-like substance;

[0035] (3) The water-soluble extract material is extracted with petroleum ether and ethyl acetate in turn. The extraction time of petroleum ether is 4h, and the extraction is performed 3 times. The remaining solution is extracted with ethyl acetate, and the extraction time is 4h, and the extraction is performed 3 times. Collect, evaporate under r...

Embodiment 2

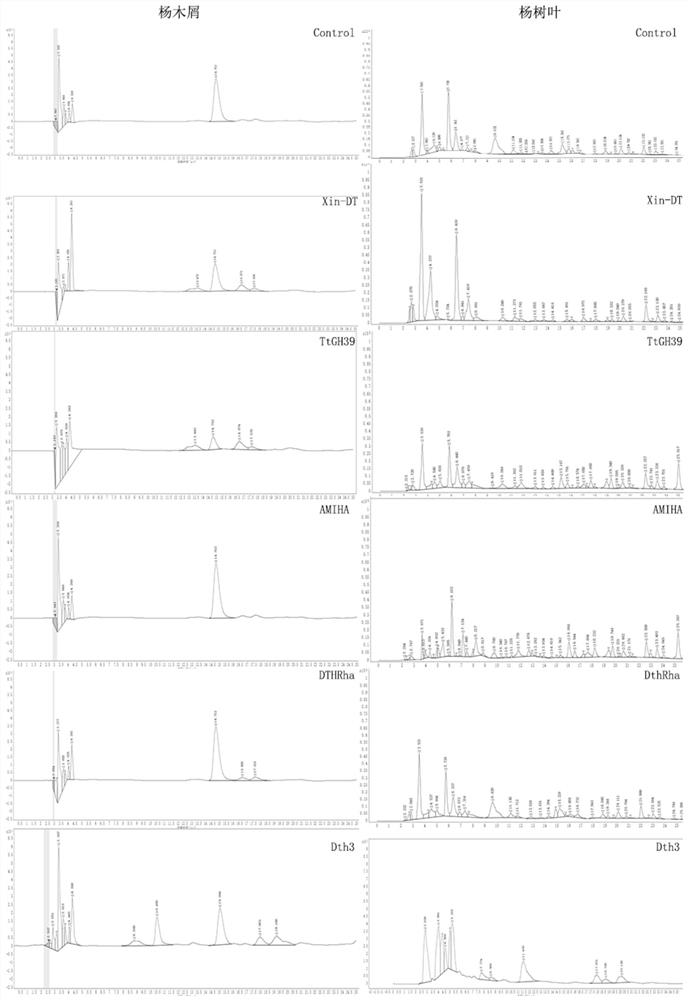

[0040] (1) Select 11 kinds of enzymes produced in the laboratory: xylosidase Xin-Dt from D. thermophilum (optimum temperature 75°C, optimum pH 6.0) and xylosidase TtGH39 from T. thermosaccharolyticum (optimum pH 6.0) Optimum temperature 50℃, optimum pH 5.5), α-rhamnosidase AMIHA from A. mulundensis (optimum temperature 65℃, optimum pH 6.0) and α-rhamnoside from D.thermophilum DSM3960 Enzyme DthRha (optimum temperature 90°C, optimum pH 6.5), and 7 kinds of β-glucosidases, respectively Dth3 (optimum temperature 85°C, optimum pH 5.5) derived from D. thermophilum DSM3960, source Tpebgl1 from T.petrophlia DSM 13995 (optimum temperature 90°C, optimum pH 6.0), Sisbgl1 from S. islandicus (optimum temperature 90°C, optimum pH 5.5), Tthbgl1 from T.thermarum DSM5069T ( Optimum temperature 90℃, optimum pH 4.8), Tthbgl3 derived from T.thermarum DSM5069T (optimum temperature 90℃, optimum pH 5.0), Tpebgl3 derived from T.petrophlia DSM 13995 (optimum temperature 90℃, optimum pH 5.0) Optimum ...

Embodiment 3

[0045] Take 20 mg of the ethyl acetate extraction phase (EAE) of poplar sawdust and poplar leaves in Example 1, dissolve in 155 μl of distilled water, add 50 μl of pH 5.5 phosphate buffer and 245 μl of β-glucosidase Dth3 (enzymatic activity 40U / ml), respectively. The poplar extracts were catalyzed by water bath reaction at 85°C, 90°C, and 95°C for 30 min, and the catalyzed products were collected.

[0046] The composition and content of the extract before and after the catalytic reaction were compared by HPLC. The experimental results are as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com