Methanol protein high-efficiency low-carbon production system and method based on biomass synthesis

A methanol protein and production method technology, applied in the field of bioengineering, can solve the problems of large carbon source consumption, emission, and large consumption, and achieve the effects of increasing oxygen solubility, realizing zero carbon emissions, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

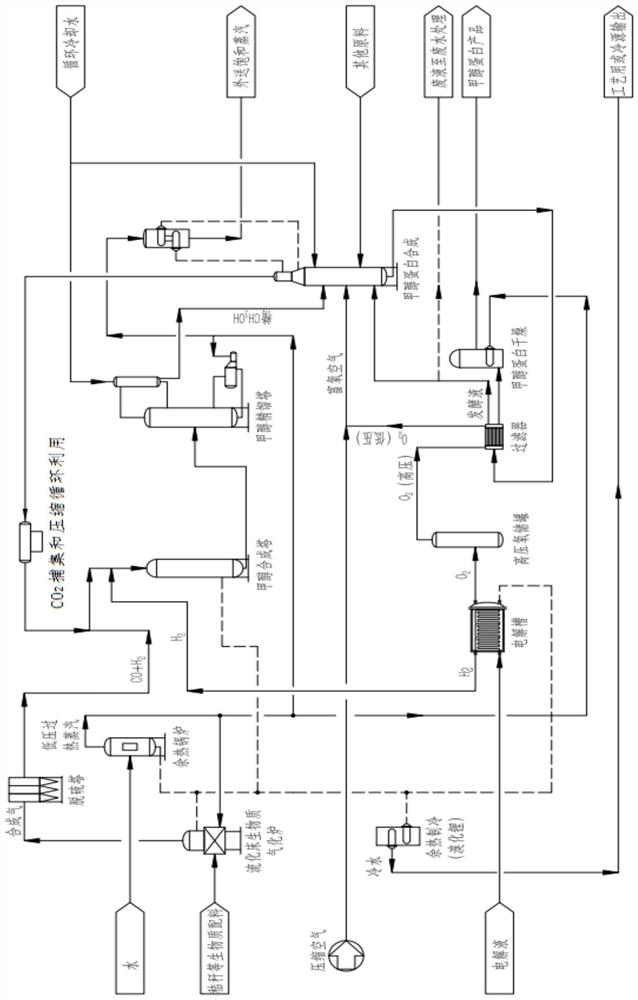

[0036] like figure 1 As shown in the figure, a high-efficiency and low-carbon production system for methanol protein based on biomass synthesis includes an electrolysis unit, an oxygen-enriched air preparation unit, a refined methanol preparation unit, a methanol protein synthesis unit, a methanol protein drying unit, a biomass gasification unit, and waste heat. A processing unit and a lithium bromide waste heat refrigeration unit; the downstream of the electrolysis unit is respectively connected to an oxygen-enriched air preparation unit and a refined methanol preparation unit; the downstream of the oxygen-enriched air preparation unit is sequentially connected to a methanol protein synthesis unit and a methanol protein drying unit, and the refined methanol The methanol protein synthesis unit is connected downstream of the preparation unit, the biomass gasification unit is connected to the refined methanol preparation unit, and the residual heat treatment unit recovers the rea...

Embodiment 2

[0042] A high-efficiency and low-carbon production method of methanol protein based on biomass synthesis using the system described in Example 1, such as figure 1 As shown, using electrolytic hydrogen production as the raw material, the by-product oxygen and air are compounded to obtain oxygen-enriched air with an oxygen-enriched content of 30% to 70%, which is introduced into the fermenter to improve the metabolic efficiency of the bacteria and correspondingly improve the production of methanol protein. Efficiency; straw biomass ingredients are processed in a fluidized bed biomass gasifier, and the biomass gas is desulfurized to participate in the reaction to synthesize methanol, which is environmentally friendly and energy-saving. At the same time, the by-product of methanol protein synthesis CO 2 After purification, compression and recovery, it is added to participate in the reaction to synthesize methanol to achieve zero carbon emissions; the three reaction heats of water e...

Embodiment 3

[0056] The high-efficiency and low-carbon production method for methanol protein based on biomass synthesis described in this embodiment specifically includes the following steps:

[0057] S0. The straw biomass ingredients are processed in a fluidized bed biomass gasifier, and the biomass synthesis gas is desulfurized to participate in the reaction to synthesize methanol, and the by-product CO of the methanol protein synthesis in the subsequent steps 2 After capturing, purifying, compressing and recovering, it is supplemented to participate in the reaction to synthesize methanol to realize CO 2 Recycling; oxygen-enriched air with an oxygen-enriched content of 30% to 70% is obtained by compounding the by-product oxygen in electrolytic hydrogen production with air, which is fed into the fermenter in subsequent steps;

[0058] S1. Shake flask seed culture

[0059] Pichia pastoris HGD-01 strain was selected and inoculated into a test tube, 2% glucose was added as a carbon source,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com