Method for directly brazing nonmetal and metal at low temperature through commercial inactive brazing filler metal

An inactive, non-metallic technology, applied in non-electric welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of difficult preparation, complex process, non-environmental metallization of non-metallic surface, etc., achieve simple process and avoid excessive reaction , using a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Embodiment 1: The present embodiment is a method for directly brazing non-metals and metals with commercial inactive solder at low temperature, which is realized according to the following steps:

[0029] 1. Cut the non-metallic material to be welded into shape, then carry out grinding and polishing treatment, and then put it into acetone and anhydrous ethanol for ultrasonic cleaning in turn, take it out and dry it to obtain the processed non-metallic material to be welded;

[0030] 2. After removing the oxide film on the surface of the metal to be welded and the brazing filler metal, put it into acetone for ultrasonic cleaning, take it out and dry it to obtain the processed metal to be welded and the brazing filler metal;

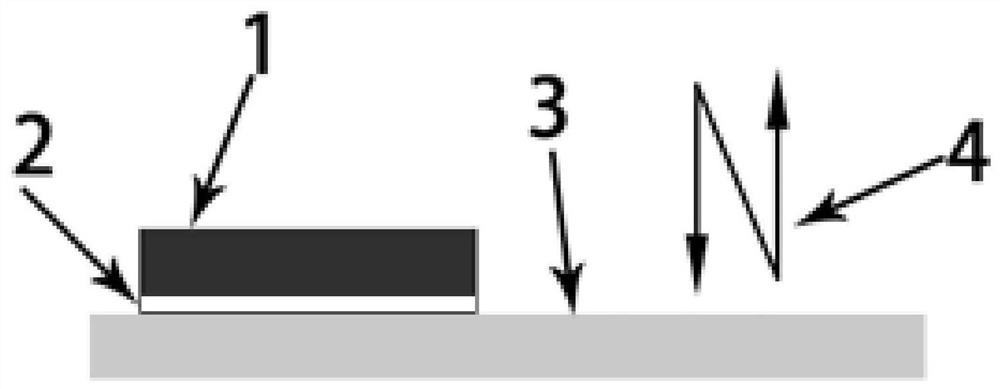

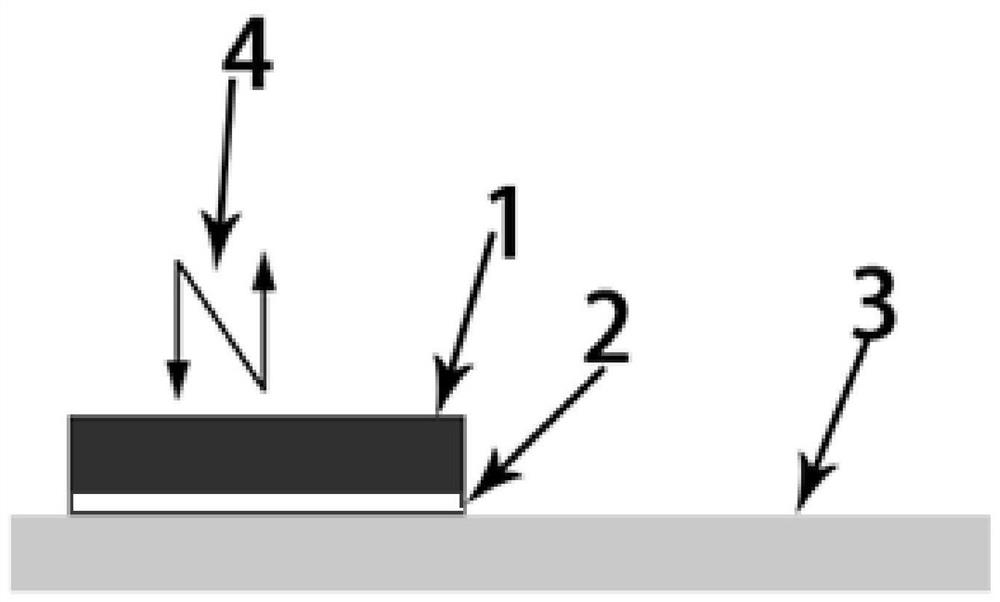

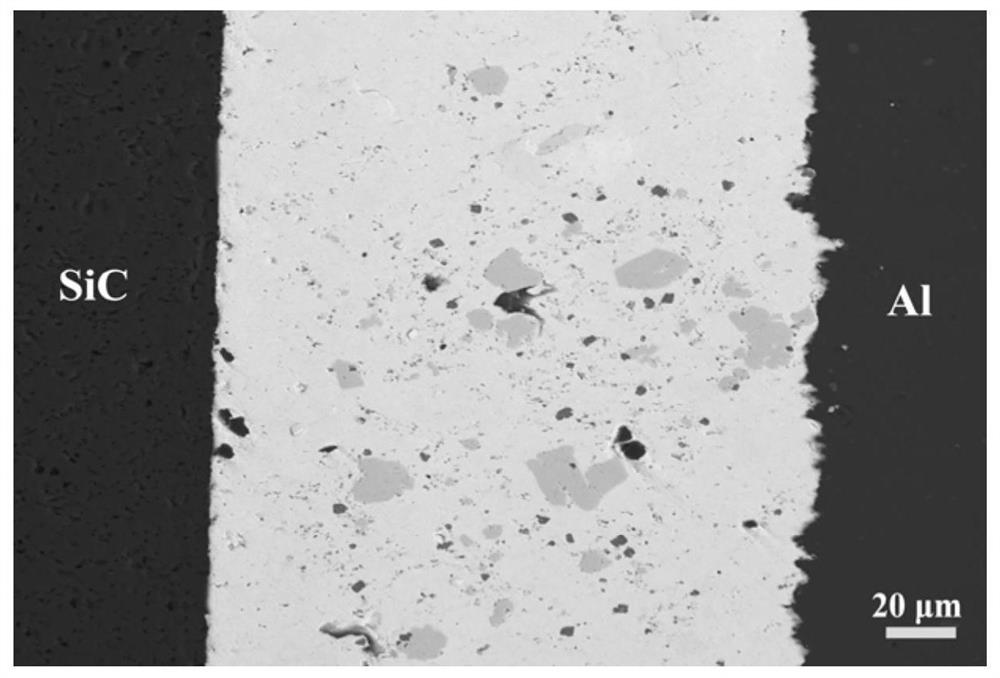

[0031] 3. Place the non-metallic material to be welded, the brazing filler metal and the clamp for the metal to be welded after the above treatment on the brazing heating platform, and heat the non-metallic material to be welded and the metal to be w...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the non-metallic materials to be welded in step 1: carbide ceramics, nitride ceramics, oxide ceramics, boride ceramics, ceramic matrix composite materials, glass, graphite , C / C composites, diamond or graphene. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the cutting in step 1: a diamond internal circular cutting machine is used. Other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com