Method for adjusting titanium-tungsten carrier pore passage in waste SCR denitration catalyst and application

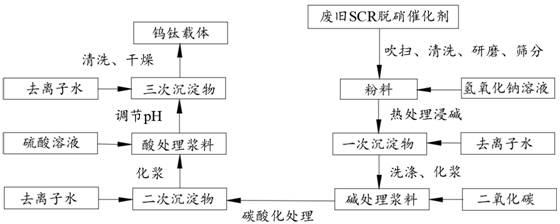

A technology for SCR catalysts and denitrification catalysts, which is applied in the field of adjusting the pores of titanium and tungsten carriers in waste SCR denitrification catalysts. It can solve the problems that cannot be directly and completely reused to prepare new catalysts, and achieve stability maintenance, pore structure optimization, and loose pore structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for adjusting the pore structure of the titanium-tungsten carrier in the spent SCR denitration catalyst, the method comprising the following steps:

[0046] Step 1: Purging the waste SCR catalyst, washing with deionized water, and grinding to obtain waste SCR denitration catalyst powder, sieving the waste SCR denitration catalyst powder, and selecting waste SCR denitration catalyst powder with a particle size range of less than 150 μm.

[0047] Step 2: Pour 1 part of the sieved waste SCR denitration catalyst powder into 6 parts of sodium hydroxide solution, the mass concentration of the sodium hydroxide solution is 5%. Mix the waste SCR denitrification catalyst powder and sodium hydroxide solution evenly, pump it into the reaction kettle, and seal the reaction kettle, react with alkali at 240°C, 100 rpm-120 rpm for 4 hours, cool and filter to obtain once sediment.

[0048] Step 3: Clean the primary sediment by using the three-stage cou...

Embodiment 2

[0054] This embodiment provides a method for adjusting the pore structure of the titanium-tungsten carrier in the spent SCR denitration catalyst, the method comprising the following steps:

[0055] Step 1: Purging the waste SCR catalyst, washing with deionized water, and grinding to obtain waste SCR denitration catalyst powder, sieving the waste SCR denitration catalyst powder, and selecting waste SCR denitration catalyst powder with a particle size range of less than 150 μm.

[0056] Step 2: Pour 1 part of the sieved spent SCR denitration catalyst powder into 5 parts of sodium hydroxide solution, the mass concentration of which is 3%. Mix the waste SCR denitrification catalyst powder and sodium hydroxide solution evenly, pump it into the reaction kettle, and seal the reaction kettle, react with alkali at 300°C, 100 rpm-120 rpm for 6 hours, cool and filter to obtain once sediment.

[0057] Step 3: Clean the primary sediment by using the three-stage countercurrent washing meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com