Ammonia decomposition furnace for exhaust of heat treatment nitriding furnace

A technology of ammonia decomposition and nitriding furnace, which is applied in the field of waste gas purification, can solve problems such as ammonia gas discharge, worker safety production hazards, and impact on the environment of workshops and factory areas, and achieve the effect of improving the ammonia gas decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

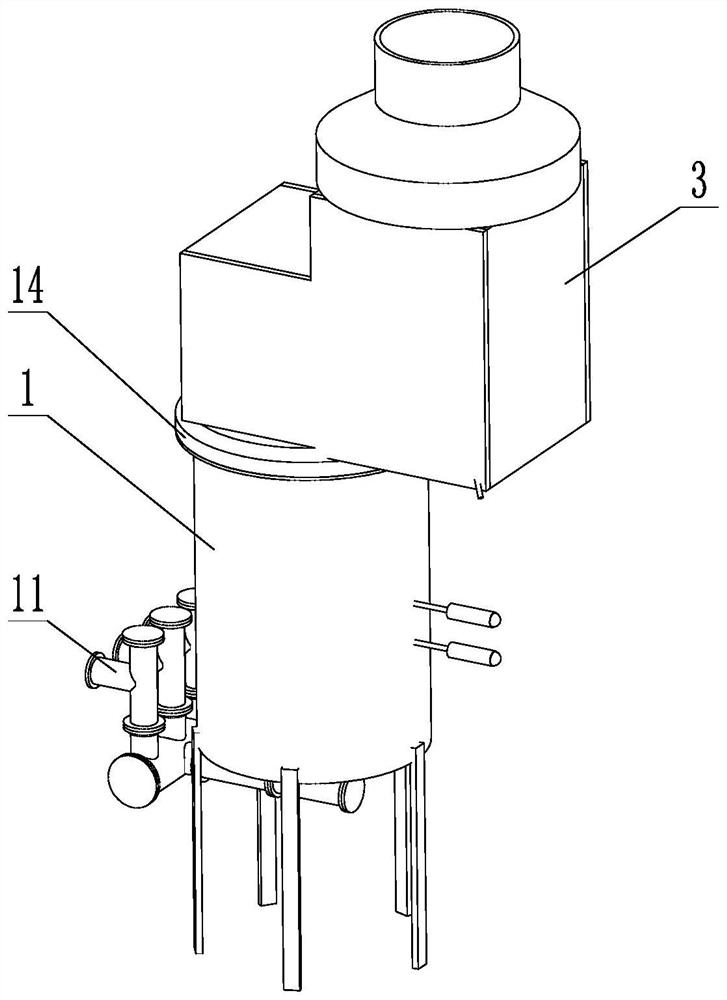

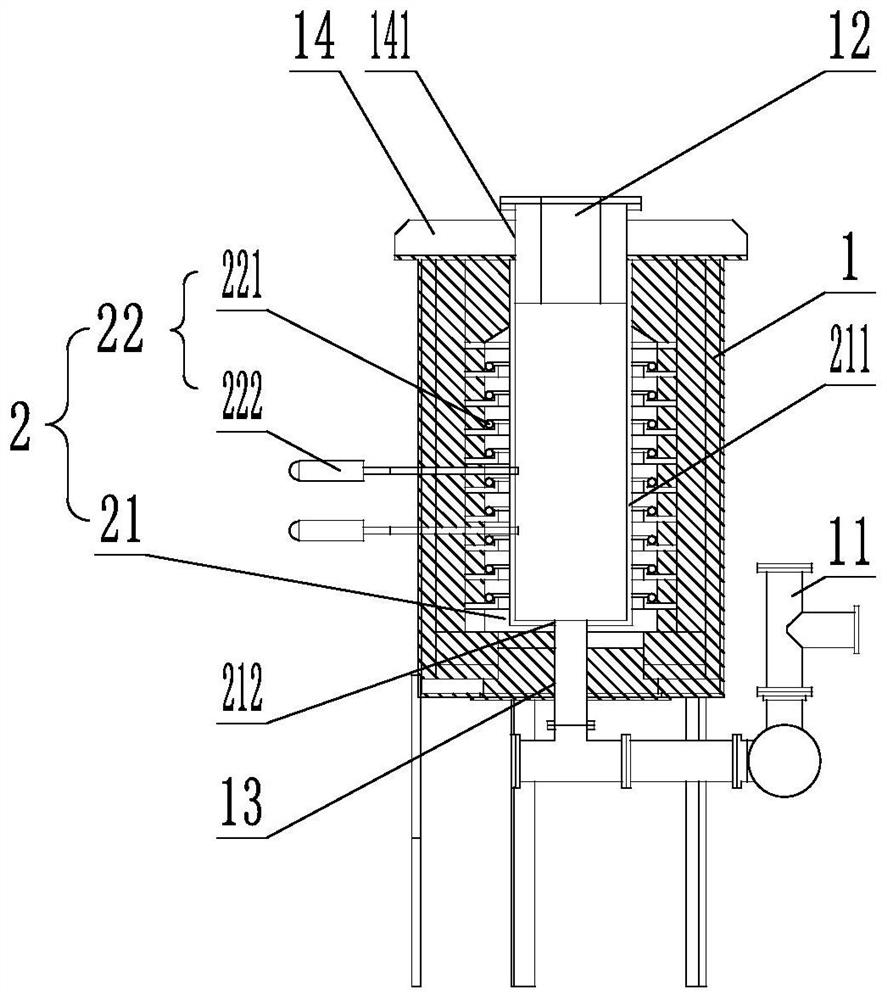

[0035] Attached to the following Figure 1-3 This application will be described in further detail.

[0036] The embodiment of the present application discloses an ammonia decomposition furnace for exhaust gas of a heat treatment nitriding furnace. refer to figure 1 and 2 , an ammonia decomposition furnace for heat treatment nitriding furnace exhaust includes a furnace body 1 , an ammonia gas purification device 2 installed inside the furnace body 1 , and a tail gas discharge device 3 installed on the top of the furnace body 1 . A support frame is set up at the bottom of the furnace body 1, an air intake pipe 11 is installed at the bottom of the furnace body 1, an exhaust port 141 is opened at the top of the furnace body 1, an exhaust pipe 12 is installed at the exhaust port 141, The gas pipe 12 connects the furnace body 1 and the exhaust gas discharge device 3 .

[0037] refer to figure 2 , the ammonia purification device 2 includes an ammonia decomposition mechanism 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com