Method for preparing crystal whisker of calcium sulphate, and phosphonic acid

A technology of calcium sulfate whiskers and phosphoric acid, applied in chemical instruments and methods, calcium/strontium/barium sulfate, crystal growth, etc., can solve the problems of environmental pollution by discharge wastewater, high cost of mineral processing, waste of sulfate radicals, etc. The effect of low anti-corrosion requirements, high decomposition rate and recovery rate of phosphate rock, and high decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

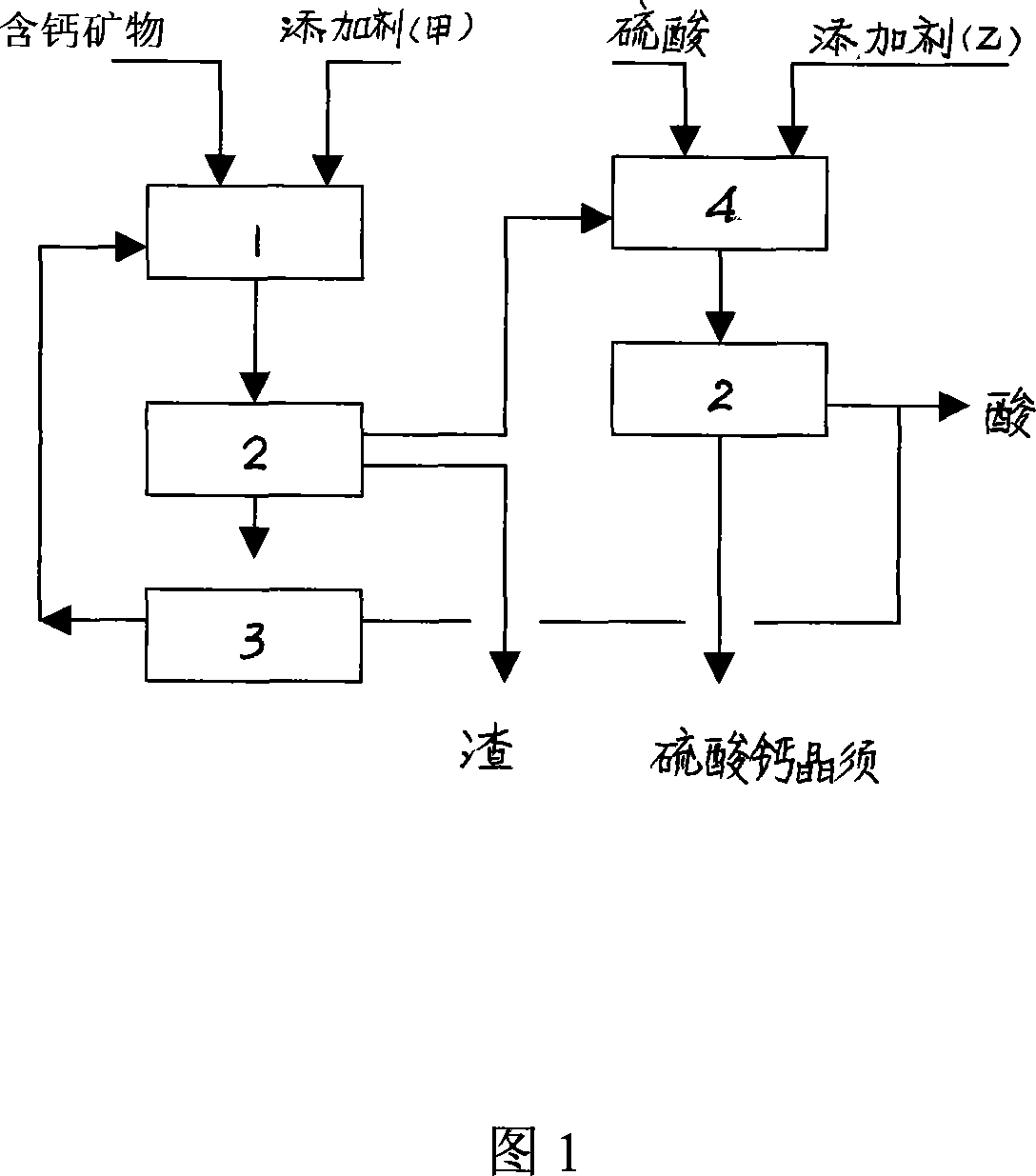

Method used

Image

Examples

Embodiment 1

[0036] 1) take P 2 o 5 120Kg of phosphate rock powder with a content of 18%, add 6Kg of composite additive A, add P 2 o 5 Concentration is 22% phosphoric acid 1440Kg, and keeping slurry temperature is 60 ℃, and reaction time is 3 hours; Wherein: compound additive formaldehyde humic acid (can be used to contain the humic acid sodium humate, potassium humate and magnesium humate Humic acid) and silicon-containing substances such as diatomaceous earth, the ratio is humic acid: diatomaceous earth=1:2;

[0037] 2) Separating the reacted slurry from liquid to solid by means of pressure filtration or vacuum filtration, washing the solid with water to neutrality and then stacking; the filtered clear liquid is sent to the next reaction procedure for use;

[0038] 3) The clear liquid obtained by the above filtration reacts with sulfuric acid with a concentration of 55% under the action of adding composite additive B, and the addition amount of composite additive B is 1.5% of the theo...

Embodiment 2

[0041] 1) take P 2 o 5 120Kg of phosphate rock powder with a content of 25%, add 1Kg of composite additive A, add P 2 o 5 Concentration is 20% phosphoric acid 1320Kg, and keeping slurry temperature is 70 ℃, and reaction time is 2.5 hours. Wherein: composite additive A is composed of humic acid and silicon-containing substance diatomite, and the ratio is humic acid:diatomite=1:5.

[0042] 2) Separating the reacted slurry from liquid to solid by means of pressure filtration or vacuum filtration, washing the solid with water to neutrality and then stacking; the filtered clear liquid is sent to the next reaction procedure for use;

[0043] 3) Filtration gained clear liquid is under the effect of adding composite additive second, and concentration is the sulfuric acid reaction of 35%, and the addition amount of composite additive is 1.0% of the theoretical generation amount of gypsum whisker output; 102%; Phosphoric acid and calcium sulfate whiskers are generated in the reactio...

Embodiment 3

[0046] 1) take P 2 o 5 120Kg of phosphate rock powder with a content of 28%, add 0.6Kg of composite additive A, add P 2 o 5 Concentration is 20% phosphoric acid 1500Kg, and keeping slurry temperature is 80 ℃, and reaction time is 2.5 hours. Wherein: composite additive A is composed of humic acid and diatomaceous earth, and the ratio is humic acid: diatomite=1:10.

[0047] 2) Use pressure filtration or vacuum filtration to separate the liquid from the solid of the reacted slurry, wash the solids until they are neutral, and then pile them up; the filtered clear liquid is sent to the next reaction program for use;

[0048] 3) Filtration gained clear liquid is under the effect of adding compound additive second, is the sulfuric acid reaction of 25% with concentration, and the addition amount of compound additive is 0.5% of the gypsum whisker output theoretical production amount; 102%; Phosphoric acid and calcium sulfate whiskers are generated in the reaction tank, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com