Silk fibroin coating modified zinc anode, preparation method and application thereof

A silk fibroin, zinc anode technology, applied in electrode manufacturing, battery electrodes, active material electrodes, etc., can solve problems such as anode instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of silk fibroin-coated zinc anode: First, silk fibroin was prepared. Cut silkworm cocoons (5g) into small pieces, put in 50ml, 0.02M Na 2 CO 3 Boil in aqueous solution for 35 minutes, rinse thoroughly with distilled water, and dry in air at room temperature. Subsequently, 0.4 g of anhydrous calcium chloride was dissolved in 15 ml of anhydrous formic acid (HCOOH) to obtain a uniform and transparent solution, and then 0.8 g of dried silk fibroin was added to the above solution under vigorous stirring until completely dissolved. The surface of the zinc foil was polished with sandpaper, then washed with deionized water and ethanol. After drying at room temperature, the silk fibroin mixed solution was coated on the zinc foil with a spatula with a thickness of 6 μm. After overnight drying, a solid was prepared. For silk fibroin coating, the dried coating was soaked in water to induce the formation of β-sheets and pores, thereby preparing a silk fibroin-coated zi...

Embodiment 2

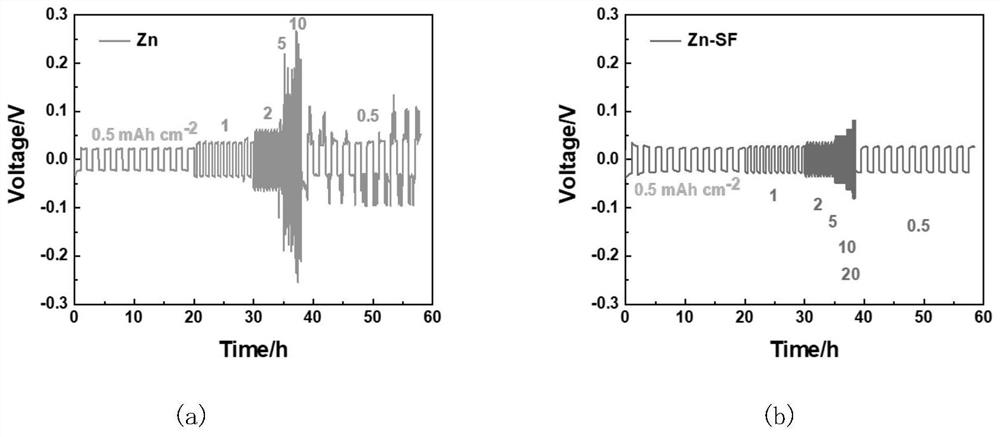

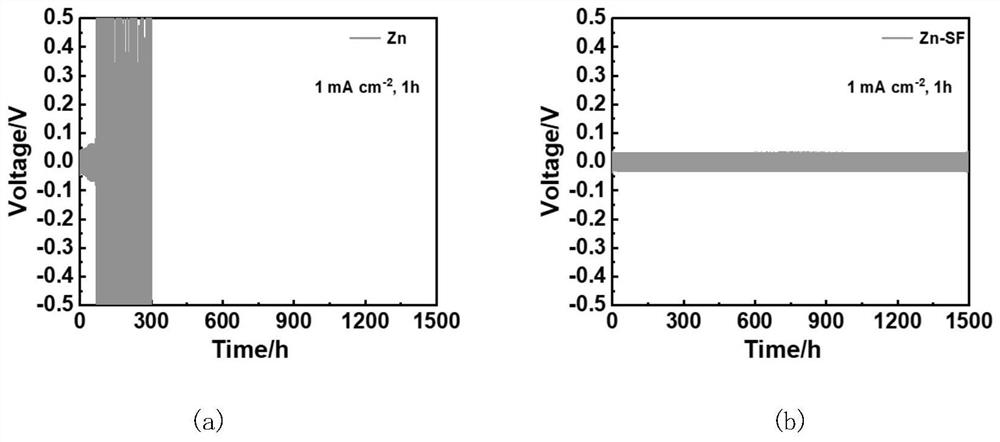

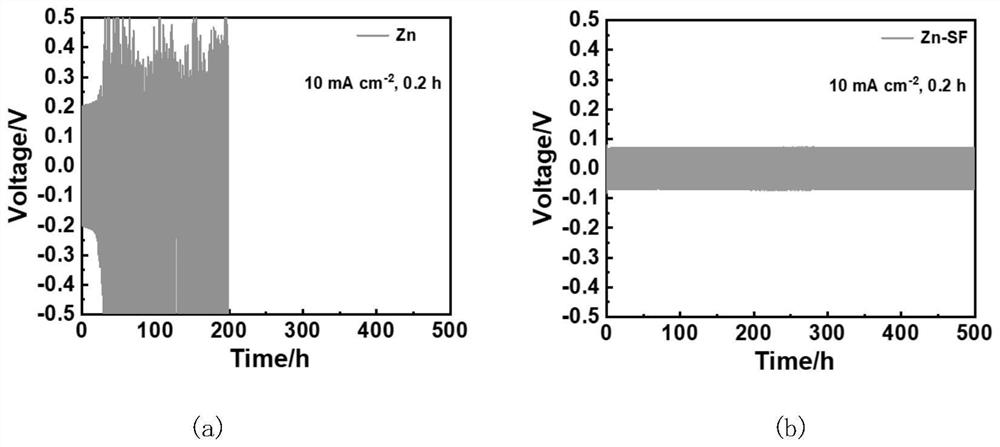

[0027] Preparation of Zn / / Zn (Zn-SF / / Zn-SF) symmetrical cells: The symmetrical cells were fabricated by using two pure Zn electrodes (or two Zn- SF electrodes were assembled as cathode and anode, respectively. 2M ZnSO 4 Aqueous solution and glass fiber separator (GF / C, Whatman) were used as electrolyte and separator, respectively, and the volume of electrolyte added was 200 μl.

[0028] Zn(Zn-SF)-Zn x V 2 O 5 ·nH 2 Preparation of O full cells: Zn x V 2 O 5 ·nH 2 O powder, acetylene black, and polytetrafluoroethylene (PTFE) were mixed in a mass ratio of 7:2:1 to prepare a self-supporting film, which was pressed onto a stainless steel mesh and cut into pieces (1x1 cm) after being vacuum-dried at room temperature 2 ) as the cathode. The mass load was measured to be 2 mg cm -2 . The cathode was assembled in a CR2025 coin cell with pure Zn or Zn-SF as anode, glass fiber separator (GF / C, Whatman) and 2M ZnSO 4 (200 μL) was used as separator and electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com