Corrosion-inhibiting primer for structural bonding and preparation method of corrosion-inhibiting primer

A corrosion-inhibiting, structural adhesive technology, applied in the direction of adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the short-term as long as 10 days, the longest is only 20 days, the epoxy resin system primer is durable Poor damp and heat performance, affecting the bonding of large metal parts, etc., achieves the effect of improving storage stability, good corrosion inhibition performance, and meeting the needs of corrosion inhibition primers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

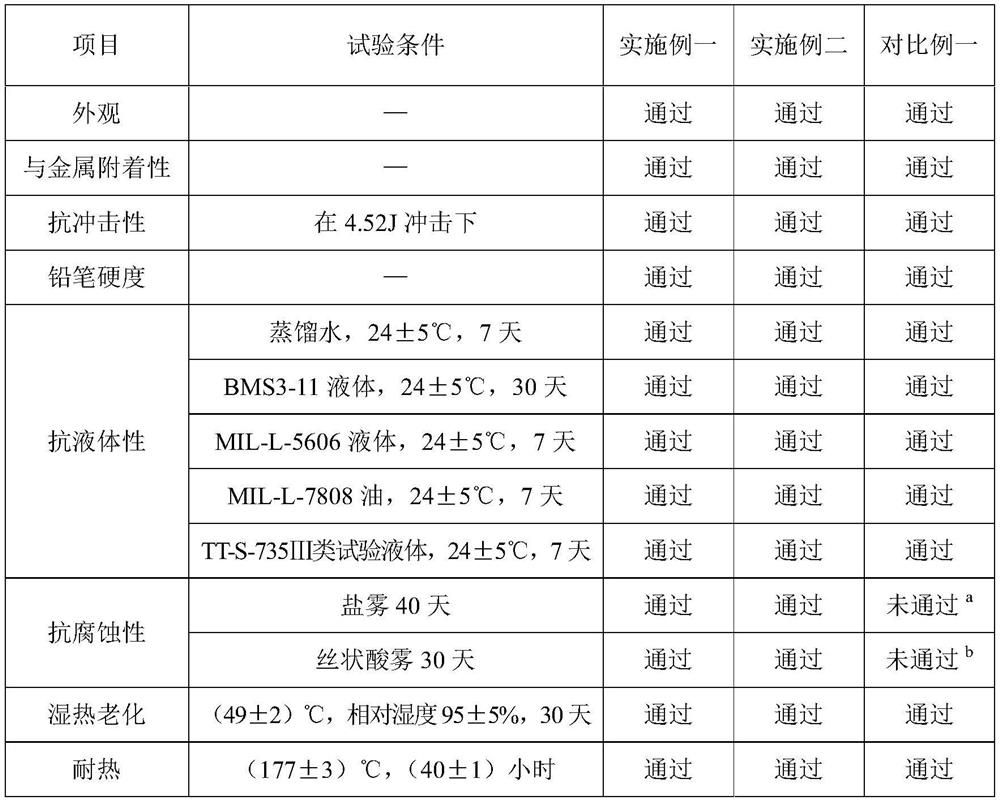

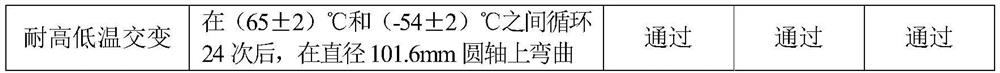

Examples

preparation example Construction

[0024] A preparation method of a corrosion-inhibiting primer for structural bonding, comprising the following steps:

[0025] ①Weigh chromate raw material, accelerator and graphene oxide by weight; mix graphene oxide and deionized water, and ultrasonically treat for 30 minutes to obtain a uniformly dispersed graphene oxide aqueous solution; add chromate raw material and make it Completely dissolve; add the mixed solution to the reaction kettle, heat up to 100°C to 120°C, and stir for 30 minutes; reduce the temperature of the reaction kettle to 30°C to 60°C, add accelerator, and stir for 30 minutes; filter the product, vacuum drying to obtain accelerator / chromate / graphene composite;

[0026] ②Weigh epoxy resin, curing agent, toughening agent and accelerator / chromate / graphene composite by weight;

[0027] ③Add epoxy resin, curing agent, toughening agent and accelerator / chromate / graphene composite into the reaction kettle, and add solvent, and the rotating speed is 200-600 rev / m...

Embodiment 1

[0029] ①Weigh 70.8g sodium dichromate, 28.8g sodium carbonate, 15g 2,4-bis(N,N-dimethyl)urea toluene accelerator and 120g graphene oxide; mix graphene oxide and deionized water, ultrasonically Treat for 30 minutes to obtain a uniformly dispersed graphene oxide aqueous solution; add sodium dichromate and sodium carbonate, and dissolve them completely; add the mixed solution to the reaction kettle, heat up to 120 ° C, and stir for 30 minutes; The temperature dropped to 50°C, 2,4-bis(N,N-dimethyl)urea toluene was added, and stirred for 30 minutes; the product was filtered and vacuum-dried to obtain accelerator / chromate / graphene composite;

[0030] ②Weigh 100g E-44 epoxy resin, 180g 0194 epoxy resin, 10g dicyandiamide curing agent, 50g carboxyl-terminated polybutadiene rubber toughener and 120g accelerator / chromate / graphene composite;

[0031] ③Add E-44 epoxy resin, 0194 epoxy resin, dicyandiamide curing agent, carboxyl-terminated polybutadiene rubber toughening agent and accelera...

Embodiment 2

[0033]①Weigh 64.9g of sodium dichromate, 26.4g of sodium carbonate, 12g of 3-(3,4-dichlorophenyl)-1,1-dimethylurea accelerator and 105g of graphene oxide; Ionized water was mixed, and ultrasonically treated for 30 minutes to obtain a uniformly dispersed graphene oxide aqueous solution; sodium dichromate and sodium carbonate were added, and the two were completely dissolved; the mixed solution was added to the reaction kettle, heated to 120 ° C, and stirred for 30 minutes; the temperature of the reactor was lowered to 40° C., 3-(3,4-dichlorophenyl)-1,1-dimethylurea was added, and stirred for 30 minutes; the product was filtered and vacuum-dried to obtain accelerator / chromium salt / graphene composite;

[0034] ②Weigh 75g E-51 epoxy resin, 200g 0191 epoxy resin, 12g dicyandiamide curing agent, 60g carboxyl-terminated nitrile rubber toughening agent and 110g accelerator / chromate / graphene composite;

[0035] ③Add E-51 epoxy resin, 0191 epoxy resin, dicyandiamide curing agent, carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com