Lignin adhesive as well as preparation method and application thereof

A technology of lignin glue and lignin, which is applied in the field of adhesives, can solve the problems of heating rate, inconsistent temperature, uneven curing, insufficient infiltration of substrates, etc., and achieve the effect of uniform curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

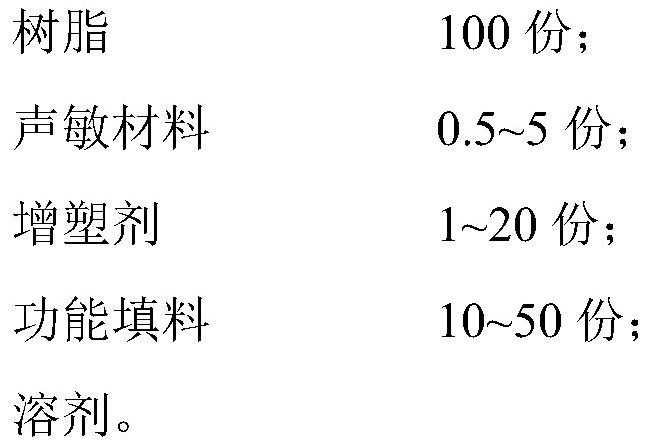

Method used

Image

Examples

Embodiment 1

[0091] This embodiment prepares a kind of lignin adhesive, and the concrete steps are:

[0092] S1. Activated lignin:

[0093] S1a. 10g of phenol was heated to 125°C, 3.5g of alkali lignin (CAS: 8068-05-1) was added thereto, and after the alkali lignin was dissolved; 0.2g of sulfuric acid aqueous solution with a concentration of 70% was added dropwise to the obtained mixture ; Due to the introduction of the acid catalyst, the pH of the reaction system is between 1 and 2;

[0094] Control the temperature to 125℃, and carry out the activation reaction for 0.5h;

[0095] S1b. Add 10 g of absolute ethanol to the reaction product obtained in step S1a, and stir evenly;

[0096] S1c. filter the obtained mixture of step S1b, collect the filtrate, and adopt distillation to remove the ethanol in the obtained filtrate;

[0097] In step S1c, the temperature and pressure of the distillation method are not limited, as long as the ethanol can be removed; however, the temperature of the di...

Embodiment 2

[0106] In this example, a lignin adhesive is prepared, and the difference from Example 1 is:

[0107] In step S3, also includes plasticizer dioctyl phthalate (CAS: 117-84-0) and functional filler silica (purchased from Shanghai McLean Biochemical Technology Co., Ltd., product number S824304);

[0108] Wherein, the mass ratio of plasticizer, functional filler and product obtained in step S2 is 1:10:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com