Water-based high-volume solid-content steel structure normal-temperature anticorrosive paint and preparation method thereof

A high-volume, steel-structured technology, applied in anti-corrosion coatings, coatings, polyester coatings, etc., can solve the problems of slow drying, low hardness of the paint film, poor water resistance and weather resistance, etc. Good appearance, simple and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

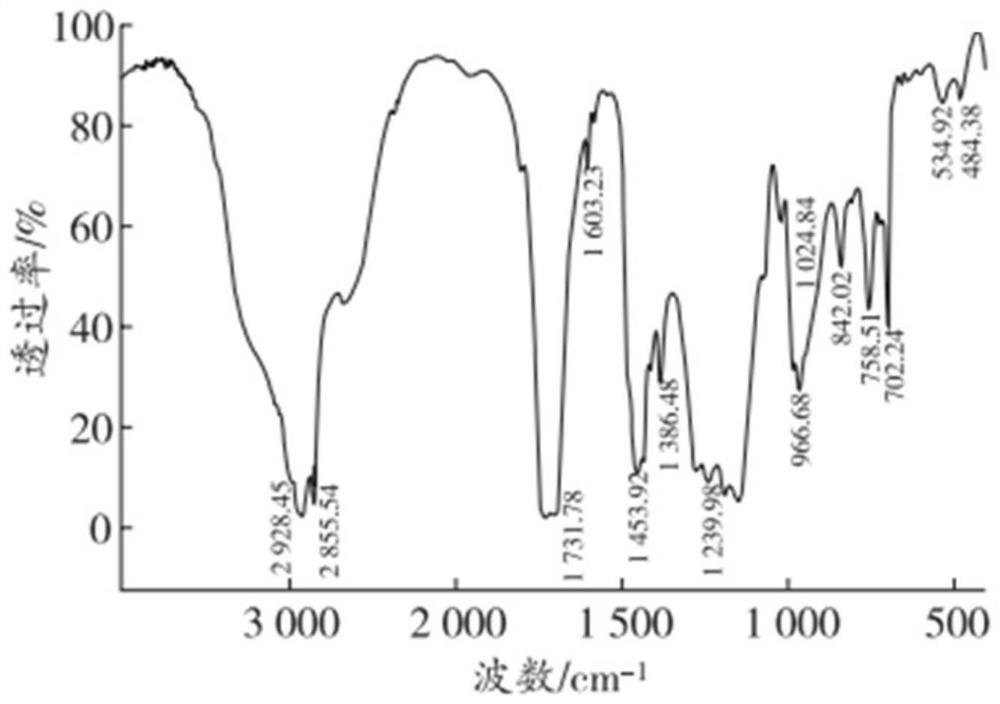

[0039] 1. Preparation of water-based acrylic modified alkyd resin

[0040] 1.1 Raw materials

[0041] Acrylic Acid, Methacrylic Acid, Monobutyl Tin Oxide, Tert-Butyl Peroxybenzoate (TBPB), Benzoyl Peroxide (BPO) (75%), Di-tert-Butyl Peroxide (DTBP), Di-tert-Butyl Peroxide (DTBP) Tert-butyl ether (DTBP) linoleic acid, linoleic acid, dehydrated ricinoleic acid, isopropanol, sec-butanol, propylene glycol methyl ether, propylene glycol butyl ether, N-methylpyrrolidone, trimethylolpropane, benzoic acid , ammonia water (25%) and ethylene glycol butyl ether are industrial grade reagents; isophthalic acid is chemically pure reagents.

[0042] 1.2 Test equipment

[0043] The test equipment and use are shown in Table 1:

[0044] Table 1 Test equipment and use

[0045]

[0046]

[0047] 1.3 Synthesis process

[0048] Preparation of acrylic prepolymer:

[0049] Add 40ml of ethylene glycol tert-butyl ether solvent to a 1000ml four-necked flask equipped with a spherical condense...

Embodiment 1

[0097] A water-based high-volume solid-containing steel structure normal temperature anti-corrosion paint, comprising the following components in parts by weight: 35 parts of water-based acrylic modified alkyd resin, 0.5 part of adhesion promoter, 0.5 part of defoamer, 1 part of anti-settling thixotropic agent parts, 1.5 parts of dispersant, 0.5 part of thickener, 0.5 part of flash rust inhibitor, 30 parts of pigments and fillers, and 20 parts of deionized water.

[0098] The preparation method of the above-mentioned water-based high-volume solid-containing steel structure normal temperature anti-corrosion paint, the preparation steps are:

[0099] (1) According to the formula amount, first add deionized water into the material preparation tank, start stirring at a low speed of 300r / min, and add dispersant, defoamer, pigment and filler in turn under stirring;

[0100] (2) After adding, the rotating speed is increased to 900r / min, and stirred for 25 minutes;

[0101] (3) After...

Embodiment 2

[0105] A water-based high-volume solid-containing steel structure normal temperature anti-corrosion paint, comprising the following components in parts by weight: 40 parts of water-based acrylic modified alkyd resin, 2 parts of dispersant, 0.7 parts of defoamer, 35 parts of pigments and fillers, anti-sinking touch 3 parts of modifier, 0.8 part of adhesion promoter, 0.7 part of thickener, 0.8 part of flash rust inhibitor, and 22 parts of deionized water.

[0106] The preparation method of the above-mentioned water-based high-volume solid-containing steel structure normal temperature anti-corrosion paint, the preparation steps are:

[0107] (1) According to the formula amount, first add deionized water into the material preparation tank, start stirring at a low speed of 200 r / min, and add dispersant, defoamer, pigment and filler in turn under stirring;

[0108] (2) After adding, the rotating speed is increased to 800r / min, and stirred for 20 minutes;

[0109] (3) After stirring...

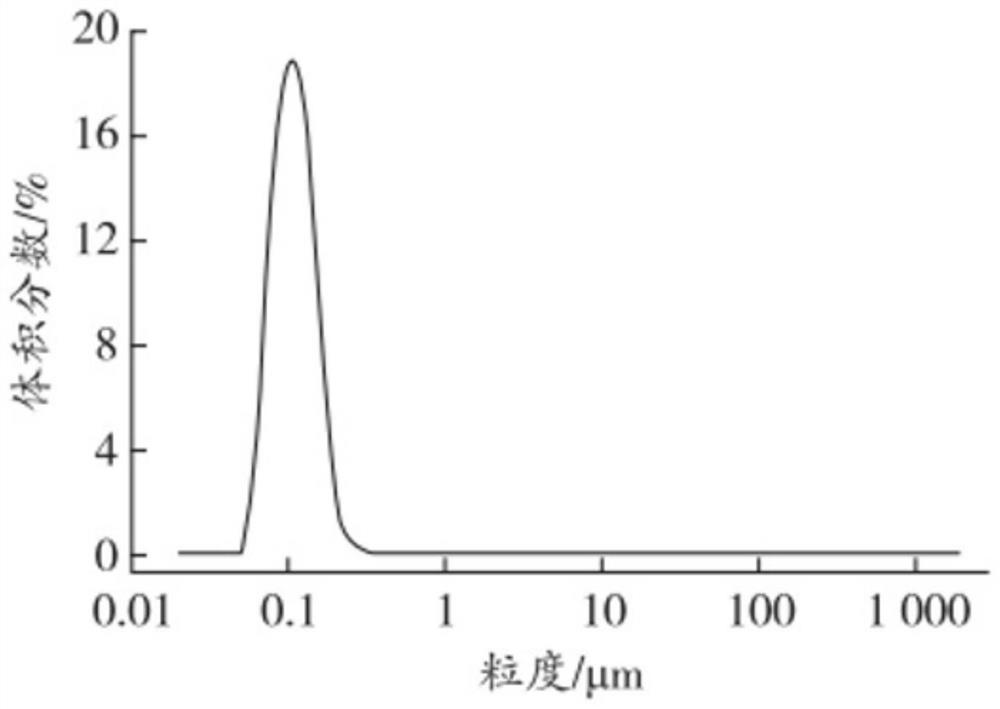

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com