Spiral carbon tube/zinc oxide/PCTG master batch and PCTG composite material containing same

A technology of zinc oxide and four-needle zinc oxide, which is applied in the field of polymer composite materials, can solve problems such as poor strength, achieve the effects of preventing interface slippage, enhancing photocatalytic antibacterial effect, and enhancing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

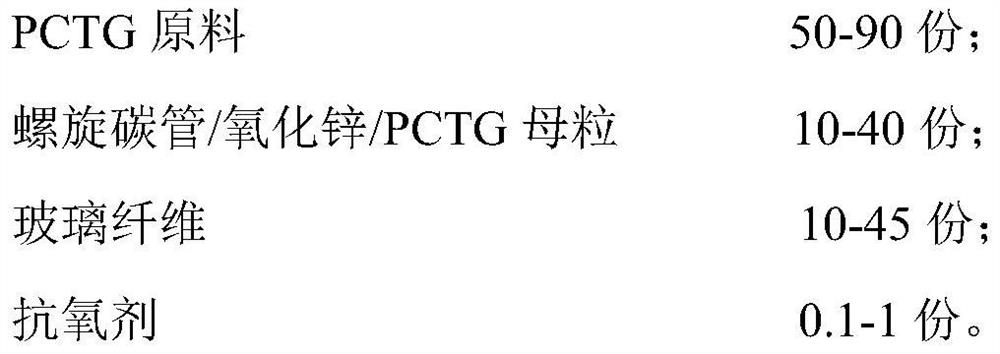

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the present embodiment spiral carbon tube / zinc oxide / PCTG master batch is as follows:

[0039]A1: Add 5 parts of carbon spiral tubes to 150 parts of nitric acid solution with a concentration of 3 mol / L, stir at room temperature for 2 hours, filter and separate out the carbon spiral tubes, wash three times with deionized water and absolute ethanol, and dry at 100 °C for 24 hours. The acidified carbon spiral tubes were added to 150 parts of hydrogen peroxide with a concentration of 30 vol.% for ultrasonic dispersion for 2 hours, the spiral carbon tubes were separated by filtration, repeatedly washed with deionized water until the pH was neutral, and filtered and dried;

[0040] A2: Premix 5 parts of spiral carbon tubes obtained in the above steps, 10 parts of four-needle zinc oxide and 30 parts of ethylene glycol by mechanical stirring for 1 h, and the mixture is mixed with terephthalic acid and 1,4-cyclohexanedimethanol according to 0.5: The rat...

Embodiment 2

[0043] The preparation method of the present embodiment spiral carbon tube / zinc oxide / PCTG master batch is as follows:

[0044] A1: Add 5 parts of carbon spiral tubes to 150 parts of nitric acid solution with a concentration of 3 mol / L, stir at room temperature for 2 hours, filter and separate out the carbon spiral tubes, wash three times with deionized water and absolute ethanol, and dry at 100 °C for 24 hours. The acidified carbon spiral tubes were added to 150 parts of hydrogen peroxide with a concentration of 30 vol.% for ultrasonic dispersion for 2 hours, the spiral carbon tubes were separated by filtration, repeatedly washed with deionized water until the pH was neutral, and filtered and dried;

[0045] A2: Premix 2 parts of spiral carbon tubes obtained in the above steps, 10 parts of four-needle zinc oxide and 30 parts of ethylene glycol by mechanical stirring for 1 h, and the mixture is mixed with terephthalic acid and 1,4-cyclohexanedimethanol according to 0.5: The ra...

Embodiment 3

[0048] The preparation method of the present embodiment spiral carbon tube / zinc oxide / PCTG master batch is as follows:

[0049] A1: Add 5 parts of carbon spiral tubes to 150 parts of nitric acid solution with a concentration of 3 mol / L, stir at room temperature for 2 hours, filter and separate out the carbon spiral tubes, wash three times with deionized water and absolute ethanol, and dry at 100 °C for 24 hours. The acidified carbon spiral tubes were added to 150 parts of hydrogen peroxide with a concentration of 30 vol.% for ultrasonic dispersion for 2 hours, the spiral carbon tubes were separated by filtration, repeatedly washed with deionized water until the pH was neutral, and filtered and dried;

[0050] A2: Premix 1 part of the spiral carbon tube obtained in the above steps, 10 parts of four-needle zinc oxide and 30 parts of ethylene glycol by mechanical stirring for 1 h, and the mixture is mixed with terephthalic acid and 1,4-cyclohexanedimethanol according to 0.5: The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com