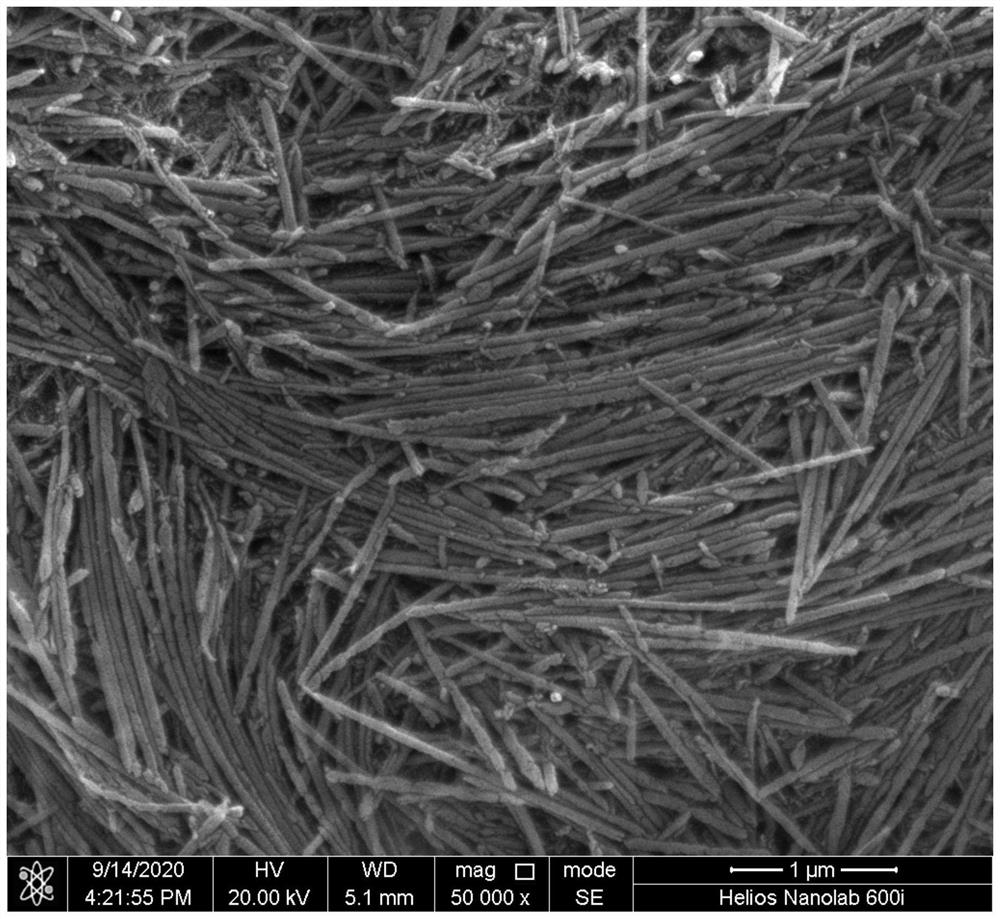

Catalyst-free controllable batch preparation method of high-strength and high-toughness boron carbide nanowires

A technology of nanowires and boron carbide, applied in the field of preparation of boron carbide nanowires, can solve the problems of easy agglomeration of carbon nanotubes, difficult removal of multi-walled carbon nanotubes, low purity of nanowires, etc., and achieves easy operation and fewer defects. , The effect of the simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment 1: The catalyst-free controllable batch preparation method of high-strength and high-toughness boron carbide nanowires of this embodiment is carried out according to the following steps:

[0024] 1. Ball milling and mixing of raw materials for boron carbide nanowire preparation

[0025] Weigh amorphous boron powder and multi-walled carbon nanotubes with a mass ratio of 4:1, add them into a ball milling jar, add an appropriate amount of ball milling balls, and perform ball milling and mixing with a certain ball milling process to obtain mixed powder;

[0026] The purity of the amorphous boron powder (B) is greater than 99%, and the purity of the multi-wall carbon nanotube (MWCNT) is greater than 99%;

[0027] The amorphous boron powder is amorphous boron; the activity of the amorphous boron powder is higher than that of the crystalline boron powder, which is favorable for diffusing with the multi-walled carbon nanotubes at a lower temperature. The im...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the diameter distribution of the amorphous boron powder in step 1 is between 200 nm and 5 μm, and the average diameter is 1 to 2 μm.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the outer diameter of the multi-walled carbon nanotubes in step 1 is 8-150 nm, the inner diameter is 4-30 nm, and the length is 5 nm. Between ~20μm; the average outer diameter is 20nm~100nm, the average inner diameter is 6nm~25nm, and the average length is 10μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com