3D printing method for preparing high-toughness TiCr2 alloy by adding Ni element

A 3D printing and alloy technology, used in additive manufacturing, metal processing equipment, additive processing, etc., can solve the limitations of molded parts, lack of ultra-high temperature alternative materials for high-temperature nickel-based alloys, etc., to achieve relatively high density, enhanced The effect of toughness and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

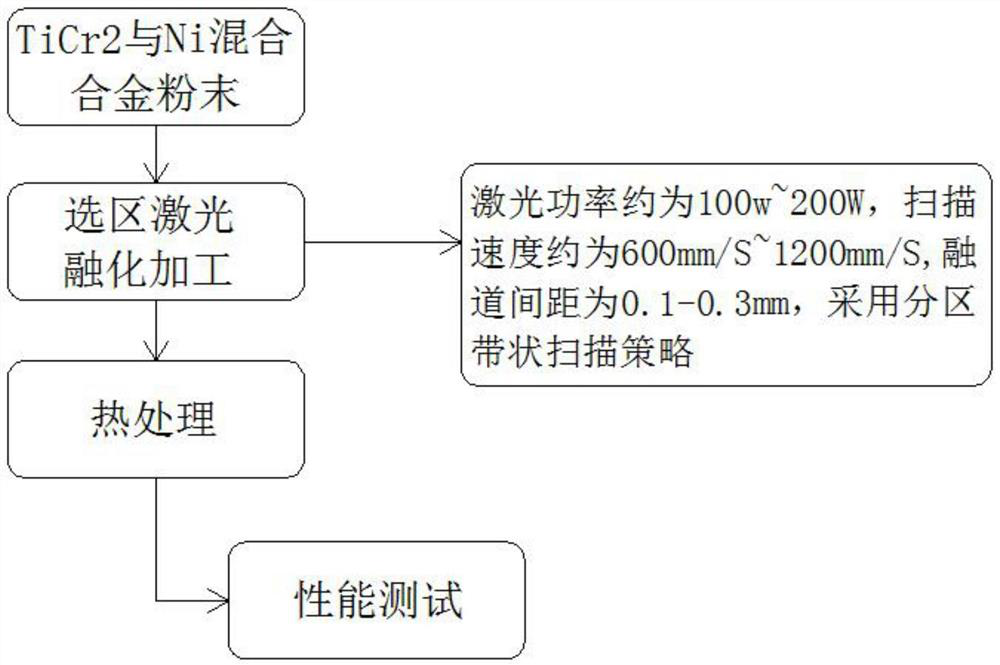

[0031] A 3D printing method for preparing high-toughness TiCr2 alloy by adding Ni element, including improving its density, strength and plasticity by selective laser melting (SLM) and annealing. The material used is a mixed powder of TiCr2 alloy powder and Ni metal powder. The equipment adopts laser selective melting equipment;

[0032] In order to realize the present invention, the specific implementation steps are as follows:

[0033] Step 1. When the laser selected area is melted and formed, turn on the power of the host, install the substrate, remove the sundries on its surface, and place it on the forming platform for leveling after air-drying;

[0034] Step 2, take the mixed powder of TiCr2 and Ni and place it in the powder feeding cylinder, open the argon gas valve, the water and oxygen content in the forming chamber is reduced to 100ppm, and the substrate is preheated;

[0035] Step 3. Selected laser melting processing, layer by layer sintering to form alloy blocks, ...

Embodiment 2

[0048] A 3D printing method for preparing high-toughness TiCr2 alloy by adding Ni element, including improving its density, strength and plasticity by selective laser melting (SLM) and annealing. The material used is a mixed powder of TiCr2 alloy powder and Ni metal powder. The equipment adopts laser selective melting equipment;

[0049] In order to realize the present invention, the specific implementation steps are as follows:

[0050] Step 1. When the laser selected area is melted and formed, turn on the power of the host, install the substrate, remove the sundries on its surface, and place it on the forming platform to level it after air-drying;

[0051] Step 2, take the mixed powder of TiCr2 and Ni and place it in the powder feeding cylinder, open the argon gas valve, the water and oxygen content in the forming chamber is reduced to 100ppm, and the substrate is preheated;

[0052] Step 3. Selected laser melting processing, layer by layer sintering to form alloy blocks, t...

Embodiment 3

[0066] A 3D printing method for preparing high-toughness TiCr2 alloy by adding Ni element, including improving its density, strength and plasticity by selective laser melting (SLM) and annealing. The material used is a mixed powder of TiCr2 alloy powder and Ni metal powder. The equipment adopts laser selective melting equipment;

[0067] In order to realize the present invention, the specific implementation steps are as follows:

[0068] Step 1. When the laser selected area is melted and formed, turn on the power of the host, install the substrate, remove the sundries on its surface, and place it on the forming platform to level it after air-drying;

[0069] Step 2, take the mixed powder of TiCr2 and Ni and place it in the powder feeding cylinder, open the argon gas valve, the water and oxygen content in the forming chamber is reduced to 100ppm, and the substrate is preheated;

[0070] Step 3: Selected laser melting processing, layer by layer sintering to form alloy blocks, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com