Defect-state catalytic membrane derived from metal organic framework as well as preparation method and application of defect-state catalytic membrane

A metal-organic framework and defect state technology, applied in the field of water treatment, can solve the problems of secondary pollution tolerance, complex catalyst preparation process, etc., and achieve high tolerance, convenient recycling and multiple utilization, and enhanced mass transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a method for preparing a metal-organic framework-derived defective catalytic membrane, comprising the following steps:

[0038] (1) In the three-electrode system, the nickel foam is used as the working electrode, and the methanol solution of 2-methylimidazole is used as the electrolyte solution, and it runs for a certain period of time under a certain potential;

[0039] (2) then adding the methanol solution of cobalt nitrate into the electrolyte solution, adjusting the potential and running for a certain period of time to obtain a foamed nickel-based ZIF-67 membrane;

[0040](3) The foamed nickel-based ZIF-67 film was calcined in a certain oxygen atmosphere to obtain a defect state catalytic film derived from the metal-organic framework.

[0041] In the present invention, the counter electrode of the three-electrode system in step (1) is preferably a Pt electrode, and the reference electrode is preferably an Ag / AgCl electrode.

[0042] I...

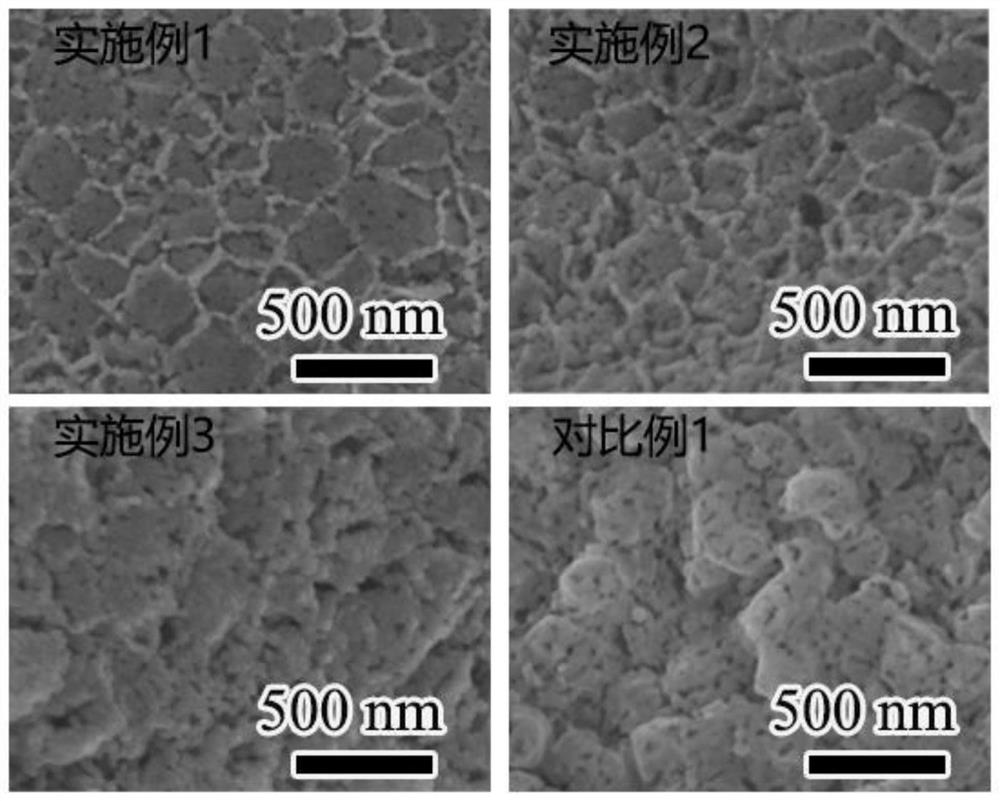

Embodiment 1

[0055] The present embodiment provides a method for preparing a metal-organic framework-derived defective catalytic membrane, comprising the following steps:

[0056] (1) In a three-electrode system, with nickel foam as the working electrode, Pt electrode as the counter electrode, Ag / AgCl electrode as the reference electrode, 50 mL of methanol solution containing 4 mmol of 2-methylimidazole as the electrolyte solution, at 1.0 V vs. Run for 1 min at Ag / AgCl potential;

[0057] (2) Then 50 mL containing 0.5 mmol Co(NO 3 ) 2 ·6H 2 The methanol solution of O was added to the above electrolyte solution, and the potential was adjusted to -1.5V vs Ag / AgCl and then run for 20 min to obtain a foamed nickel-based ZIF-67 film, which was recorded as NFZ film;

[0058] (3) After cleaning and drying the NFZ film, it was placed in a muffle furnace, the oxygen pressure was set to 5Pa, the temperature was raised to 450°C at a heating rate of 5°C / min, and calcined at 450°C for 2 hours to obt...

Embodiment 2

[0060] This embodiment provides a metal-organic framework-derived defect state catalytic membrane. For details, refer to Embodiment 1. The difference is that the oxygen pressure in step (3) is set to 10Pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com