Negative-pressure automatic feeding system and NO preparation system and method

A technology of automatic feeding and negative pressure, applied in chemical instruments and methods, methods of chemically changing substances by using atmospheric pressure, nitric oxide, etc., can solve problems such as introducing nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

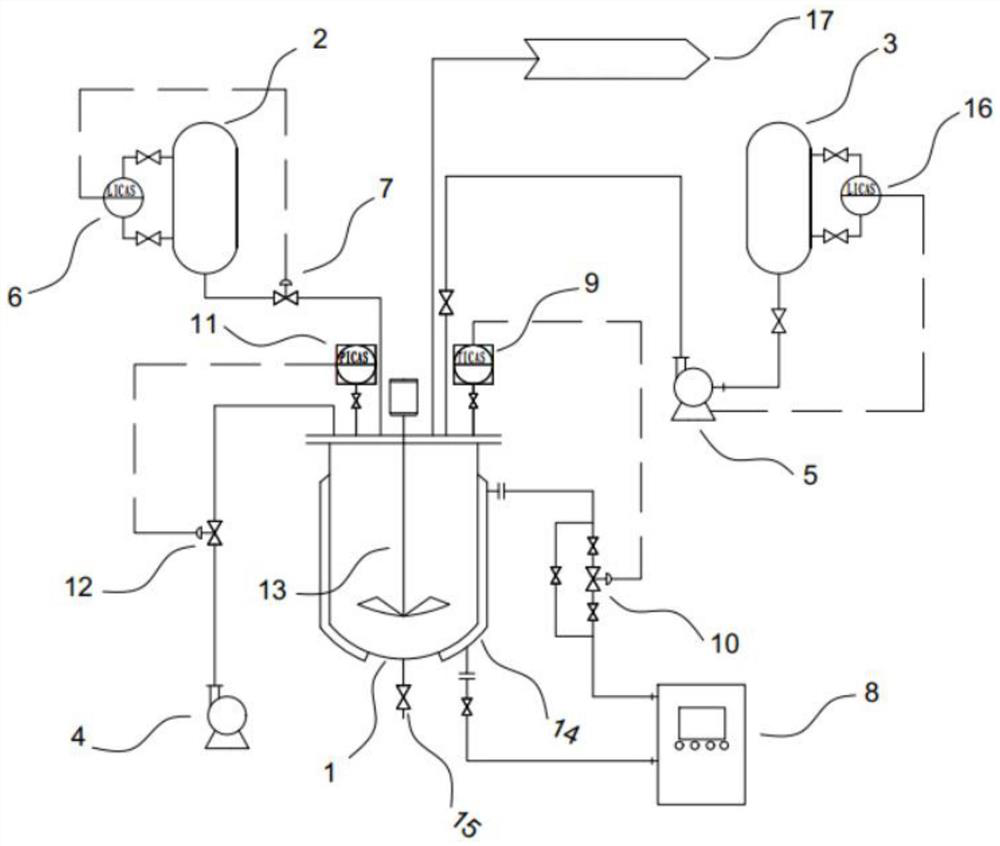

[0056] use figure 1 The apparatus shown produces NO crude product.

[0057] The solid sodium nitrite was dissolved in water to prepare 18 L of a sodium nitrite solution with a concentration of 40 wt %, and the sodium nitrite solution was added to the first storage container 2 . 12 L of dilute sulfuric acid with a volume fraction of 25% was prepared by mixing 98% concentrated sulfuric acid with water, and adding the dilute sulfuric acid into the second storage container 3 . Use oil-free vacuum pump 4 to evacuate the 50L reactor 1 to a pressure of -0.088MPa. The sodium nitrite solution is sucked into the reaction kettle 1 by negative pressure. When the remaining volume of the solution in the first storage container 2 is 3L, the first liquid level gauge 6 controls the liquid level gauge automatic control valve 7 to close and stop feeding. The metering part 5 adds the dilute sulfuric acid into the reaction kettle 1. When the volume of the remaining dilute sulfuric acid in the se...

Embodiment 2

[0062] use figure 1 The apparatus shown produces NO crude product.

[0063] The solid sodium nitrite was dissolved in water to prepare 21 L of a sodium nitrite solution with a concentration of 35 wt %, and the sodium nitrite solution was added to the first storage container 2 . 15 L of dilute sulfuric acid with a volume fraction of 20% was prepared by mixing 98% concentrated sulfuric acid with water, and adding the dilute sulfuric acid into the second storage container 3 . Use the oil-free vacuum pump 4 to evacuate the inside of the 50L reactor 1 to a pressure of -0.086MPa. The sodium nitrite solution is sucked into the reaction kettle 1 by negative pressure. When the remaining volume of the solution in the first storage container 2 is 3.5L, the first liquid level gauge 6 controls the liquid level gauge automatic control valve 7 to close and stop feeding. The metering part 5 adds dilute sulfuric acid into the reaction kettle 1. When the volume of the remaining solution in th...

Embodiment 3

[0068] use figure 1 The apparatus shown produces NO crude product.

[0069]The solid sodium nitrite was dissolved in water to prepare 32 L of a sodium nitrite solution with a concentration of 42 wt %, and the sodium nitrite solution was added to the first storage container 2 . 23 L of dilute sulfuric acid with a volume fraction of 28% was prepared by mixing concentrated sulfuric acid with a mass fraction of 98% and water, and the diluted sulfuric acid was added to the second storage container 3 . Use oil-free vacuum pump 4 to evacuate the 100L reactor 1 to a pressure of -0.083MPa. The sodium nitrite solution is sucked into the reactor 1 by negative pressure. When the remaining volume of the solution in the first storage container 2 is 4L, the first liquid level gauge 6 controls the liquid level gauge automatic control valve 7 to close and stop feeding. The metering part 5 adds dilute sulfuric acid into the reaction kettle 1, and when the volume of the remaining solution in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com