Preparation method of skin-core structure electrostatic spinning nanofiber

A nanofiber and electrospinning technology is applied in the field of preparation of skin-core structure electrospinning nanofibers, which can solve the problems of low content of nanofiber skin-core nanofibers, high precision, difficult cleaning and maintenance, etc. Simple, improved thermal performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

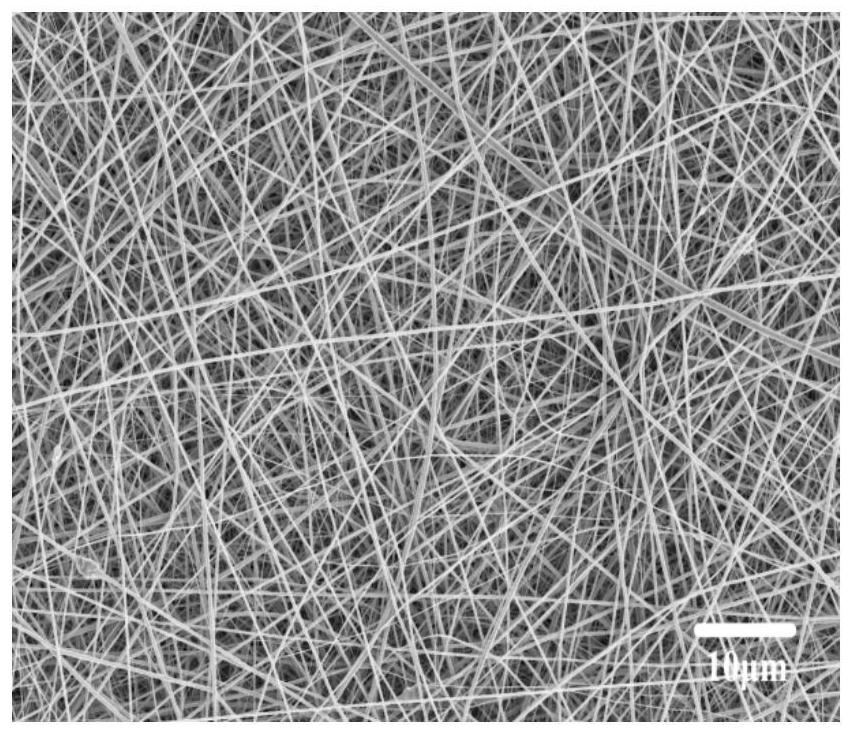

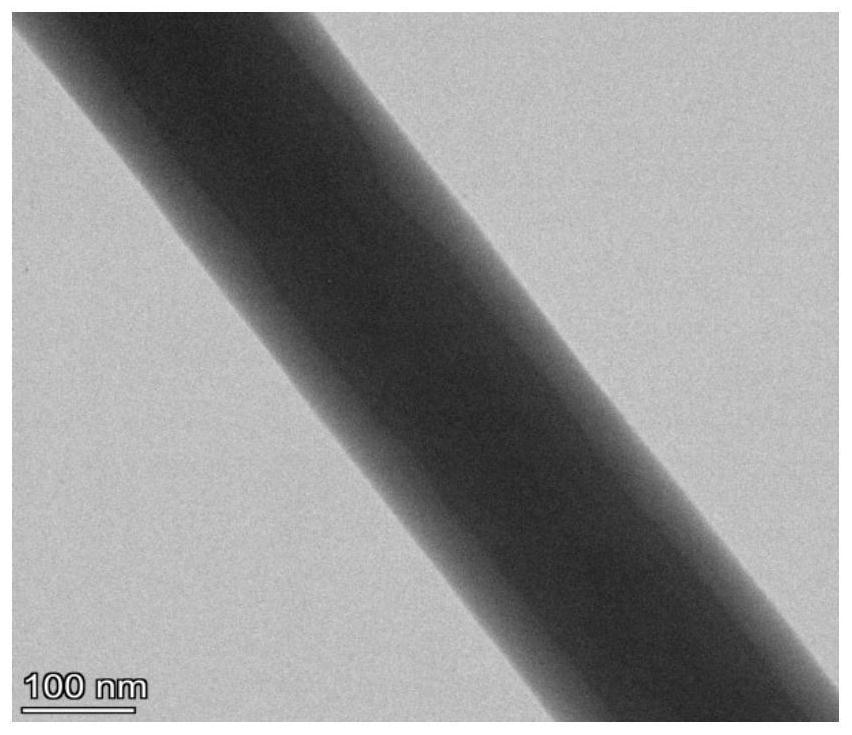

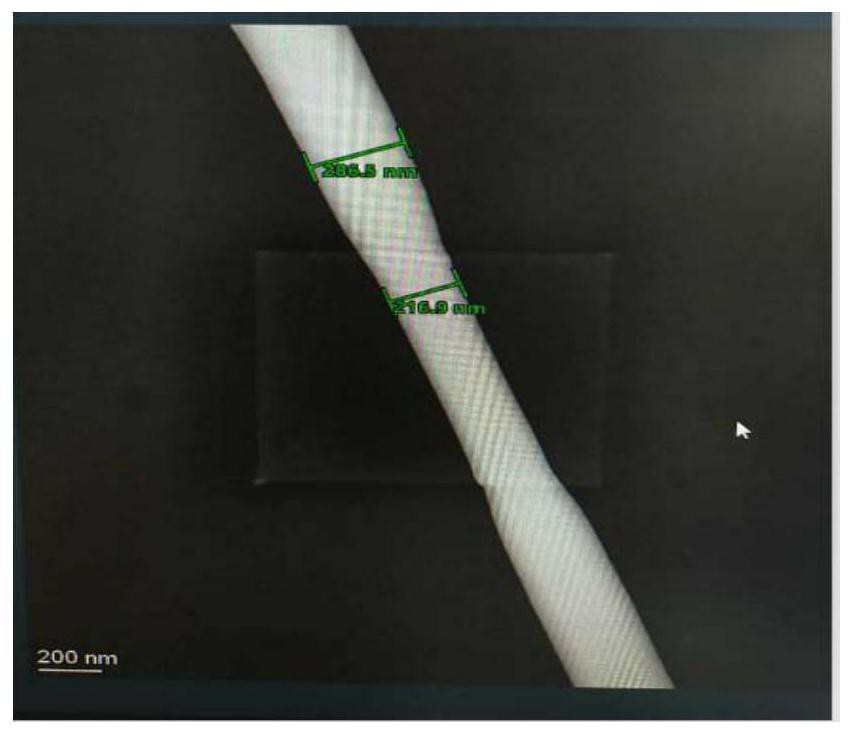

Image

Examples

Embodiment 1

[0038] A preparation method of a skin-core structure electrospinning nanofiber, the specific preparation steps are as follows:

[0039] (1) prepare organic montmorillonite, and the concrete preparation process is as follows:

[0040] (1.1) 10 g of sodium-based montmorillonite was added to 200 mL of deionized water to obtain a montmorillonite dispersion;

[0041] (1.2) 7.2 g of tetradecyltributylphosphonium bromide was added to the montmorillonite dispersion obtained in step (1.1), and the reaction was stirred at 40° C. for 8 hours, followed by centrifugation and 50% ethanol. The aqueous solution is washed, freeze-dried, and ground through a 200-mesh sieve to obtain organic montmorillonite;

[0042] (2) Add 0.016 g of the organic montmorillonite prepared in the above steps and 0.8 g of polylactic acid into 10 mL of hexafluoroisopropanol, stir at room temperature for 12 hours to obtain a mixed solution, and prepare a skin-core structure electrospun nanometer by electrospinning ...

Embodiment 2

[0052] A preparation method of a skin-core structure electrospinning nanofiber, the specific preparation steps are as follows:

[0053] (1) prepare organic montmorillonite, and the concrete preparation process is as follows:

[0054] (1.1) 10 g of calcium-based montmorillonite was added to 200 mL of deionized water to obtain a montmorillonite dispersion;

[0055] (1.2) 7.1 g of tetradecyltrimethylphosphonium bromide was added to the montmorillonite dispersion obtained in step (1.1), and the reaction was stirred at 25° C. for 12 hours, and then centrifuged in turn, mixed with 50% ethanol The aqueous solution is washed, freeze-dried, and ground through a 200-mesh sieve to obtain organic montmorillonite;

[0056] (2) Add 0.0012 g of the organic montmorillonite obtained in the above steps and 1.2 g of collagen into 10 mL of hexafluoroisopropanol, stir at room temperature for 12 hours to obtain a mixed solution, and prepare the skin-core structure electrospun nanometers by electro...

Embodiment 3

[0059] A preparation method of a skin-core structure electrospinning nanofiber, the specific preparation steps are as follows:

[0060] (1) prepare organic montmorillonite, and the concrete preparation process is as follows:

[0061] (1.1) 10g lithium-based montmorillonite was added to 150mL of deionized water to obtain a montmorillonite dispersion;

[0062] (1.2) 7.7g of cetylpyridinium bromide was added to the montmorillonite dispersion obtained in step (1.1), and the reaction was stirred at 80°C for 4h, followed by centrifugation, washing with 50% ethanol aqueous solution, Freeze-dry, grind and pass through a 200-mesh sieve to obtain organic montmorillonite;

[0063] (2) Add 0.08 g of the organic montmorillonite prepared in the above steps and 0.8 g of polycaprolactone into 10 mL of hexafluoroisopropanol, stir at room temperature for 12 hours to obtain a mixed solution, and prepare the skin-core structure electrostatically by electrospinning Spinning nanofibers; the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com