Texture baffle capable of reducing semiconductor coating stress residue

A semiconductor and texture technology, applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve problems such as peeling, increase surface adhesion thickness, surface stress residual, etc., to reduce design cost, switching and testing Convenient and fast, reducing the effect of stress residual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

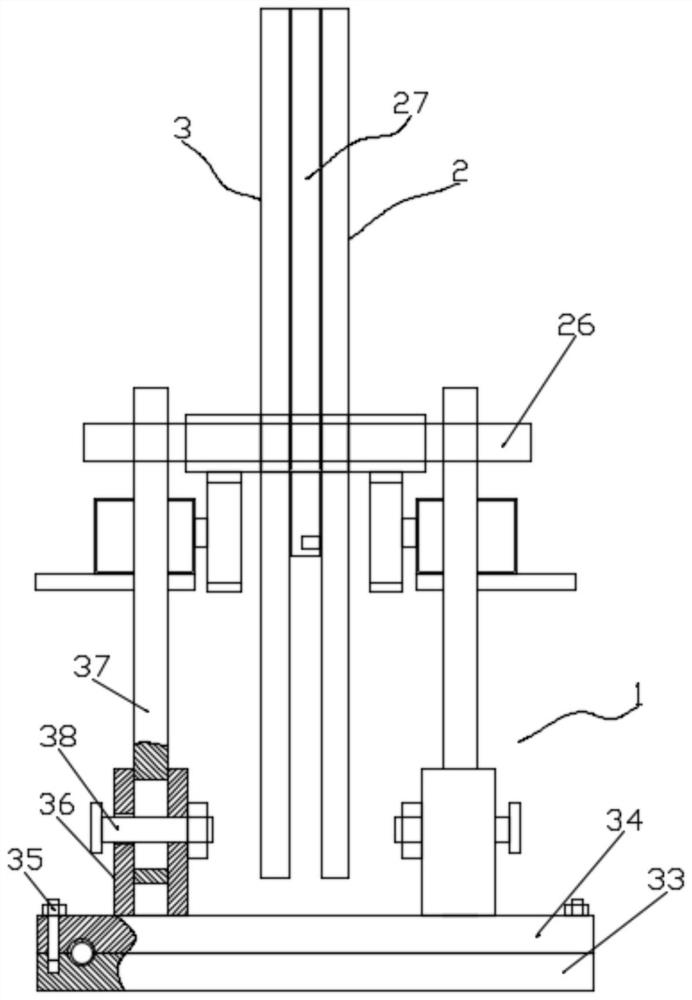

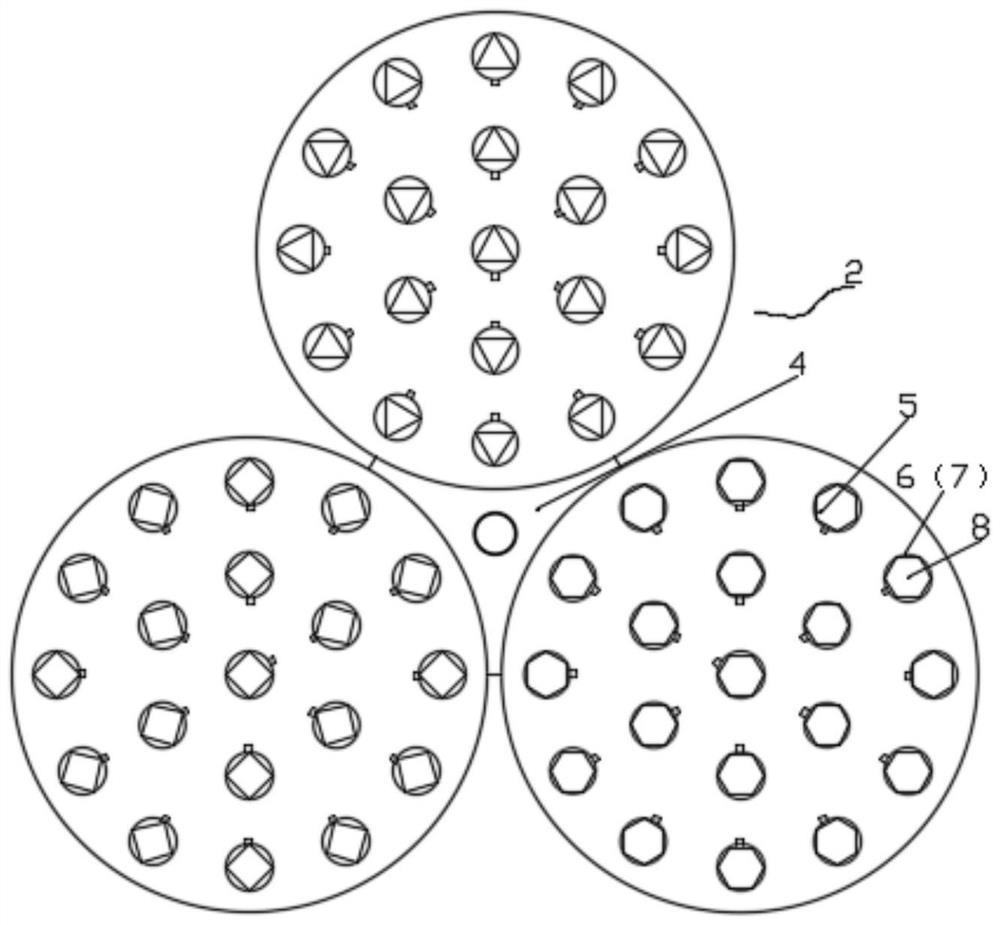

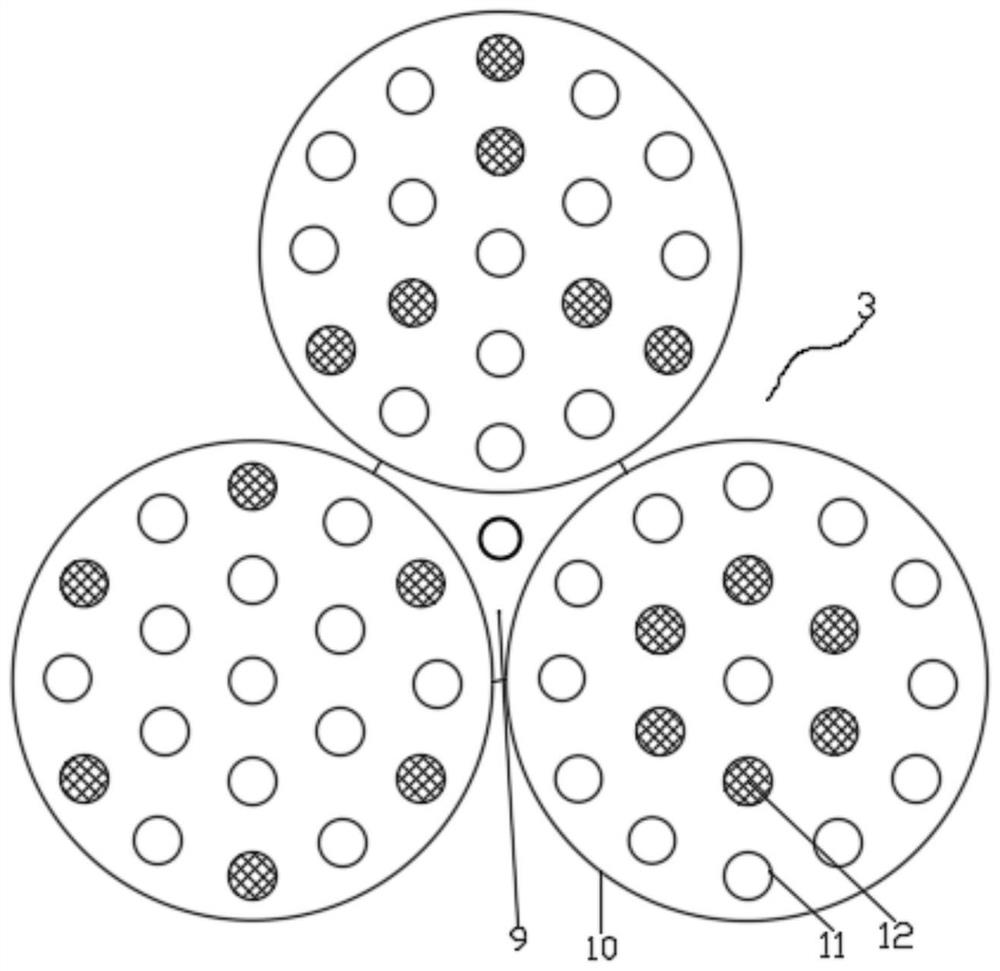

[0030] like figure 1 As shown, the present invention is a texture baffle capable of reducing the residual stress of semiconductor coating, comprising a mounting bracket 1, a texture shape transforming plate 2 and a texture shape shielding plate 3 which are coaxially rotatably arranged on the mounting bracket 1, such as figure 2 As shown, the texture shape changing plate 2 includes a first central connecting plate 4, and three groups of single-textured plates 5 annularly evenly distributed in the circumferential direction of the first central connecting plate 4. 120° evenly distributed. A plurality of first through holes 6 are uniformly arranged on the single-texture board 5 in an array, and a texture module 7 is matched in the first through hole 6. The texture module 7 is provided with a texture through hole 8, and the texture through hole 8 is divided into three shapes. They are triangles, quadrilaterals and hexagons, respectively, and the sandblasting or thermal spraying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com