Jade simulating stone die

A technology of imitating jade and stone, applied in the direction of mold fixtures, mold auxiliary parts, manufacturing tools, etc., can solve problems such as chipping, falling off, and uneven curing time of materials, so as to reduce stress residue, delay curing time, and improve production Efficiency and product quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

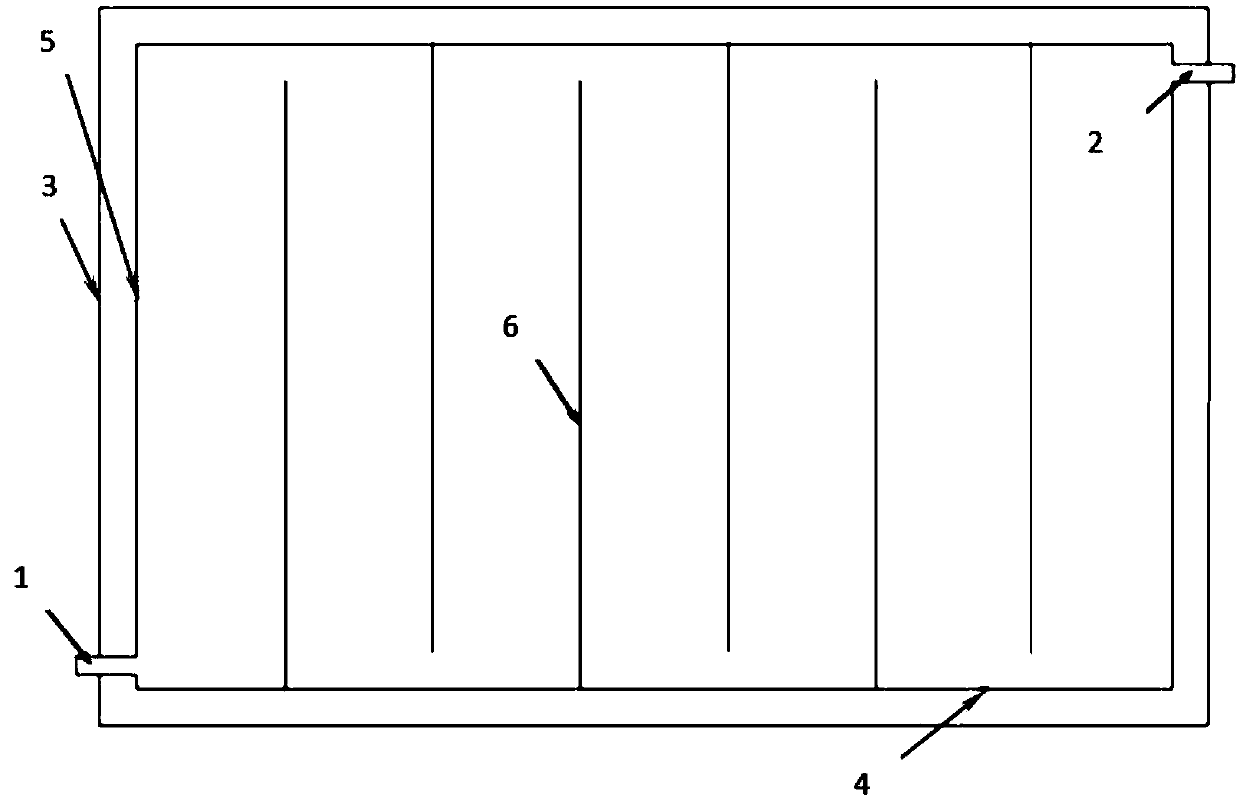

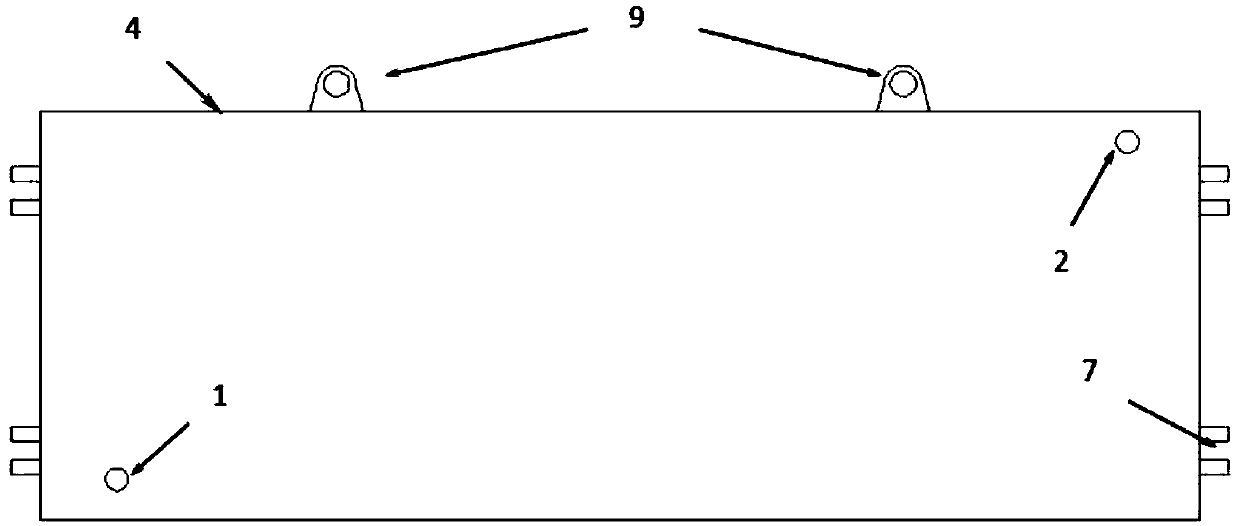

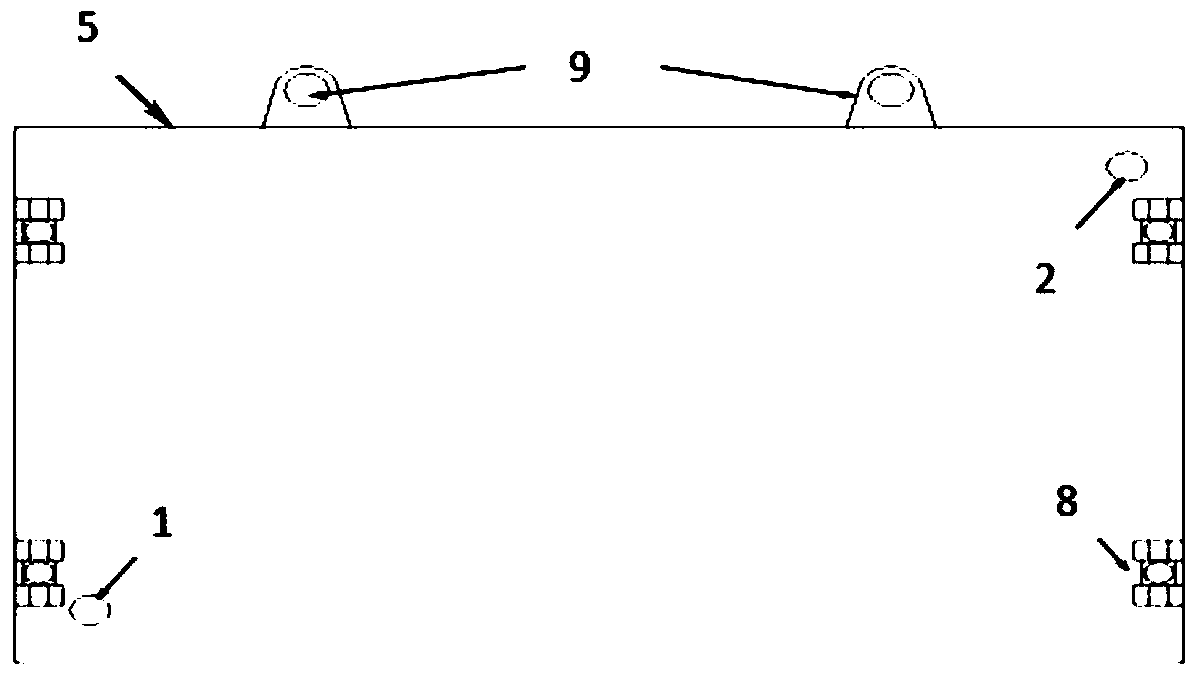

[0021] Such as Figure 1-3 Shown: a jade imitation stone mold, including water inlet 1, water outlet 2, bottom plate 3, long side plate 4, short side plate 5, partition plate 6, nut buckle 7, single head fixed screw rod 8, lifting ring 9 , the water inlet 1 is set on the left bottom of the long side plate 4 and the short side plate 5, the water outlet 2 is set on the right top of the long side plate 4 and the short side plate 5, and the nut buckle 7 is set on the long side plate On the left and right sides of the side plate 4, the single-head fixed screw 8 is arranged on the left and right sides of the short side plate 5, and the nut buckle 7 is matched with the single-head fixed screw 8, so that the bottom plate 3, the long The side plate 4 and the short side plate 5 surround and form a large groove, and the partition plate 6 separates the inside of the large groove, wherein 6 partition plates 6 are parallel to the short side plate 5 to form 7 small grooves, and each small gr...

Embodiment 2

[0031] Such as Figure 1-3 Shown: a jade imitation stone mold, including water inlet 1, water outlet 2, bottom plate 3, long side plate 4, short side plate 5, partition plate 6, nut buckle 7, single head fixed screw rod 8, lifting ring 9 , the water inlet 1 is set on the left bottom of the long side plate 4 and the short side plate 5, the water outlet 2 is set on the right top of the long side plate 4 and the short side plate 5, and the nut buckle 7 is set on the long side plate On the left and right sides of the side plate 4, the single-head fixed screw 8 is arranged on the left and right sides of the short side plate 5, and the nut buckle 7 is matched with the single-head fixed screw 8, so that the bottom plate 3, the long The side plate 4 and the short side plate 5 surround and form a large groove, and the partition plate 6 separates the inside of the large groove, wherein 6 partition plates 6 are parallel to the short side plate 5 to form 7 small grooves, and each small gr...

Embodiment 3

[0041] Such as Figure 1-3 Shown: a jade imitation stone mold, including water inlet 1, water outlet 2, bottom plate 3, long side plate 4, short side plate 5, partition plate 6, nut buckle 7, single head fixed screw rod 8, lifting ring 9 , the water inlet 1 is set on the left bottom of the long side plate 4 and the short side plate 5, the water outlet 2 is set on the right top of the long side plate 4 and the short side plate 5, and the nut buckle 7 is set on the long side plate On the left and right sides of the side plate 4, the single-head fixed screw 8 is arranged on the left and right sides of the short side plate 5, and the nut buckle 7 is matched with the single-head fixed screw 8, so that the bottom plate 3, the long The side plate 4 and the short side plate 5 surround and form a large groove, and the partition plate 6 separates the inside of the large groove, wherein 6 partition plates 6 are parallel to the short side plate 5 to form 7 small grooves, and each small gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com