Polymer cement waterproof paint and method for preparing waterproof coating layer

A waterproof coating and polymer technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of large residual stress of the coating, large shrinkage of cement, and reduced service life, so as to improve the use of Long life, not easy to crack, and reduce the effect of stress residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of polymer cement waterproof coating

[0048] Preparation of component A

[0049] Add 12kg of deionized water in the liquid stirring tank, open the stirring tank, set the stirring speed as 80 rpm, then add 82kg of acrylic acid emulsion in the stirring tank and continue to stir for 20 minutes, then add 3kg of nano-titanium dioxide, 1.5kg of dispersant and 1.5kg of preservative were stirred for 30 minutes to obtain component A.

[0050] Preparation of component B

[0051] Add 91.8kg of Portland cement into the twin-shaft powder mixer for stirring, then add 37.5kg of calcium carbonate powder and 15kg of silicon micropowder, continue stirring for 20 minutes, add 4.5kg of shrinkage reducing agent, 1.2kg of water reducing agent and stir for 60 minutes , to obtain component B.

[0052] 2. Coating

[0053] Mix component A and component B to obtain a waterproof coating, coat the above-mentioned flexible waterproof coating with a thickness of 2 mm on the surfac...

Embodiment 2~ Embodiment 5

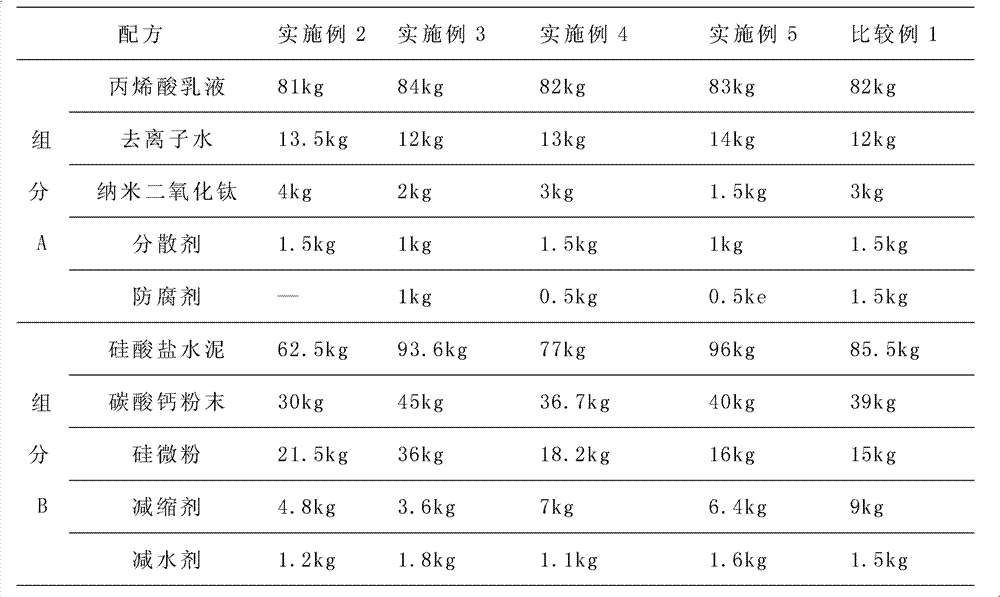

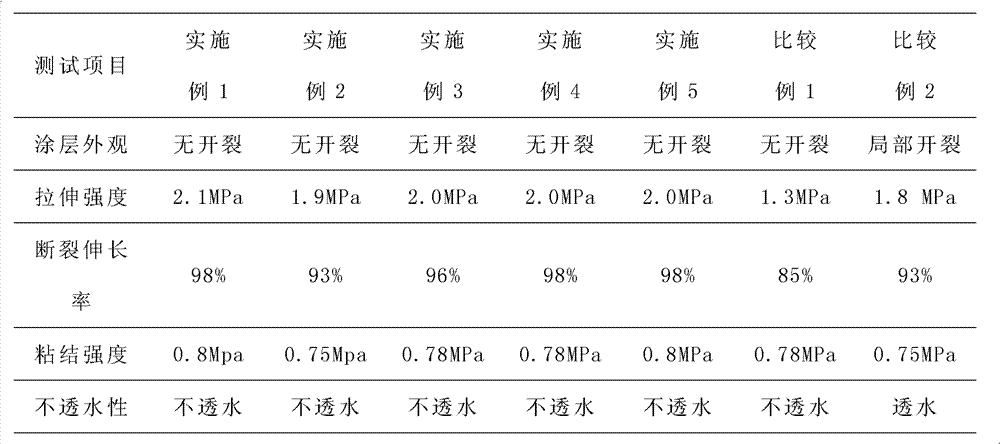

[0055] The polymer cement waterproof coating formula that above-mentioned 4 embodiments prepare is listed in Table 1, and the preparation method of embodiment 3~embodiment 5 is identical with embodiment 1, and the preparation method of the component B of embodiment 2 is identical with embodiment 1, Component A preparation method is as follows:

[0056] Preparation of component A

[0057] Add deionized water to the liquid stirring tank, open the stirring tank, set the stirring speed to 80 rpm, then add acrylic acid emulsion to the stirring tank and continue stirring for 20 minutes, then add nano-titanium dioxide and dispersant to the stirring tank in sequence, After stirring for 30 minutes, component A was obtained.

[0058] The coating method of embodiment 2~embodiment 4 is identical with embodiment, and embodiment 5 is coated according to following method:

[0059] Mix component A and component B to obtain a waterproof coating, coat the above-mentioned flexible waterproof c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com