Finish paint composite and preparation method and use method thereof

A composition and topcoat technology, applied in the direction of pretreatment surface, device for coating liquid on surface, polyurea/polyurethane coating, etc., can solve the problem of high photoinitiator content, insufficient paint film adhesion, and fast light curing speed and other problems, to achieve the effect of short curing time, reduced internal stress residual, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method of the above-mentioned topcoat composition, comprising:

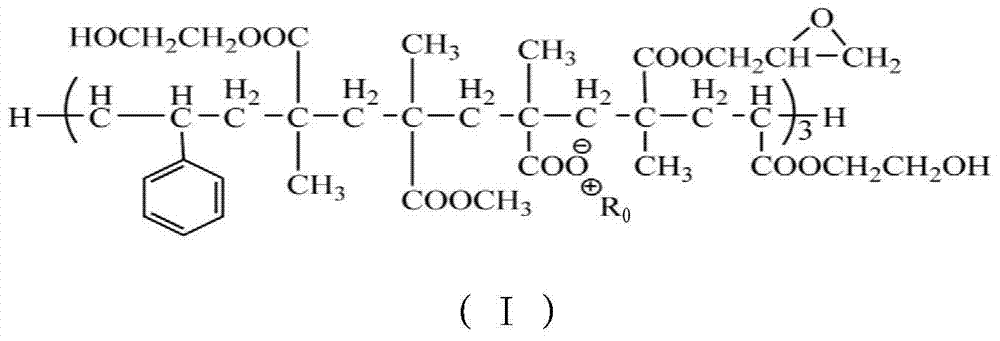

[0049] a) Add pigments and fillers and the water-based hydroxyacrylic resin with the structure shown in (I) to the additives in turn, stir for the first time, and grind after stirring to obtain the first top coat;

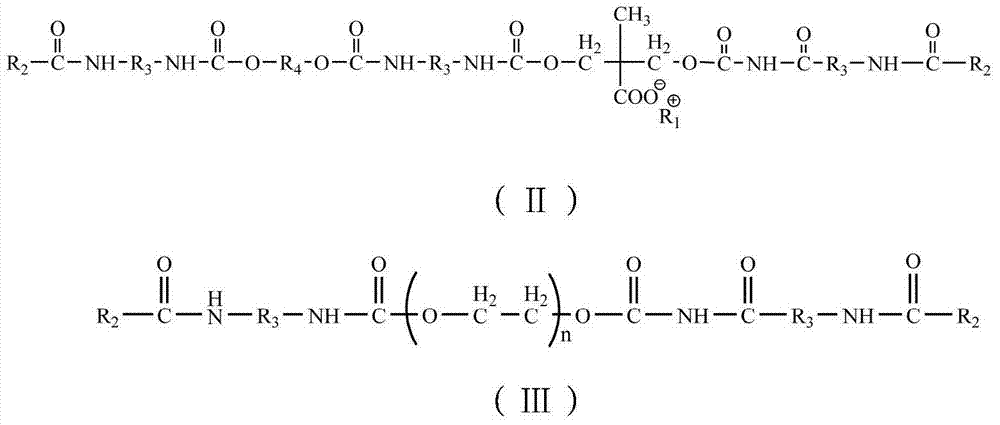

[0050] b) Add water-based polyurethane acrylic resin, cross-linking agent, deionized water and photoinitiator to the first topcoat with the structure shown in (II) or (III) and stir for the second time, filter after stirring, get topcoat;

[0051]

[0052] R in formula (Ⅰ) 0 is a tertiary amino group, R in formula (II) and formula (III) 1 is a tertiary amino group, R 2 is a hydroxyacrylate group, R 3 is a diisocyanate group, R 4 is a polymer diol group, 20≤n≤60. The process of stirring the additives, pigments and water-based hydroxyacrylic resin can be a method well known to those skilled in the art, such as stirring the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com