Organogel electrolyte, extremely low temperature zinc-air battery prepared from organogel electrolyte and preparation method of extremely low temperature zinc-air battery

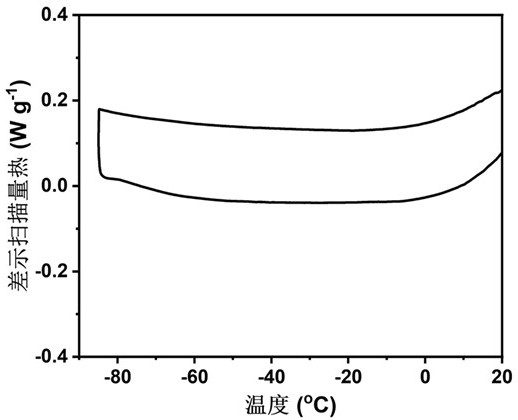

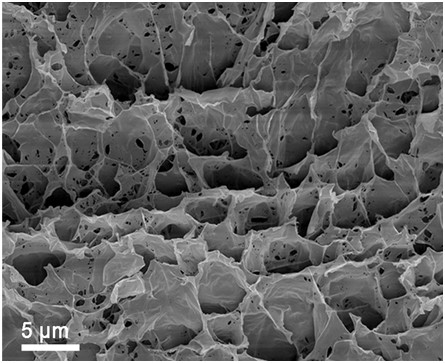

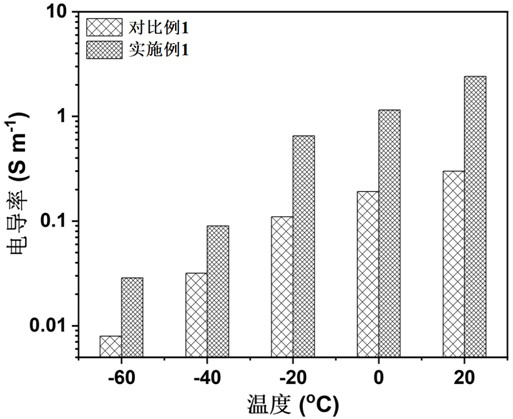

An organic gel and air battery technology, which is applied to fuel cell type half cells and primary cell type half cells, electrical components, secondary batteries, etc., can solve problems such as inability to meet low temperature use, limited application, easy freezing, etc. , to achieve low interface resistance and ion transport resistance, stable charge-discharge cycle performance, and good low temperature tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0112] Reference Example 1: Preparation method of nitrogen-doped graphene-anchored atomically dispersed Fe site catalyst

[0113] In 30mL graphene aqueous solution (mass concentration is 2mg·mL -1 ), add 20mg Fe(NO 3 ) 2 ·6H 2 O, at 20kHz, 240W, ultrasonically disperse for 1h, then add 300mg carbon nitride nanosheets, stir at room temperature for 2h, put 30mL of the mixed solution in a 50mL airtight hydrothermal kettle, and conduct a hydrothermal reaction at 180 ℃ for 12h, Cool, take out the black hydrogel, freeze-dry it at -25 °C for 72 h, and then place it in a tube furnace under a high-purity nitrogen atmosphere at a rate of 3 °C·min -1 The temperature was raised to 800°C, the temperature was kept for 3 hours, and the high temperature treatment was carried out, and then cooled to room temperature, and it was finished.

reference example 2

[0114] Reference Example 2: Preparation method of nitrogen-doped graphene-supported carbon-coated Fe nanoparticle catalyst

[0115] 2 mL of FeCl 3 ·6H 2 O ethanol solution (the mass concentration is 5 mg·mL -1 ) and 2 mL of CoCl 2 ·6H 2 O ethanol solution (the mass concentration is 5 mg·mL -1 ) was added to 200 mg of glucose and 1 g of carbon nitride powder, ground at a speed of 100 r / min for 30 min, and then placed in a tube furnace under a high-purity nitrogen atmosphere at a rate of 3 °C·min -1 The temperature was raised to 900°C, the temperature was kept for 2 hours, and the high temperature treatment was carried out, and then cooled to room temperature, and finished.

reference example 3

[0116] Reference Example 3: Mo-α-Co(OH) 2 the preparation method of

[0117] 27.3 mg (0.1 mmol) of molybdenum pentachloride, 249 mg (1.0 mmol) of cobalt acetate tetrahydrate and 1206 mg (9.0 mmol) of sodium oxalate were mixed and dissolved in 20 mL of ethylene glycol solvent, and stirred at room temperature at 1000 r / min for 1 h. , to obtain solution A; add 60 mg of sodium hydroxide to 10 mL of ethylene glycol solution, at room temperature, at a speed of 1000 r / min, and stir for 1 h to obtain solution B; mix solutions A and B, at room temperature, at a speed of 1000 r / min, Stir for 1 h, and then put 30 mL of the mixed solution in a 50 mL airtight polytetrafluoroethylene hydrothermal kettle for solvothermal reaction at 200 °C for 16 h, naturally cool to room temperature, wash 3 times with deionized water, centrifuge, at 60 °C, 20kPa Under vacuum drying for 24h, it is ready.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com