High-performance all-solid-state supercapacitor based on gel polymer electrolyte and preparation method thereof

A gel polymer, supercapacitor technology, applied in the field of energy storage, can solve the problems of volatile, flammable, easy to leak liquid electrolytes, achieve good electrochemical performance, good low temperature tolerance, and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

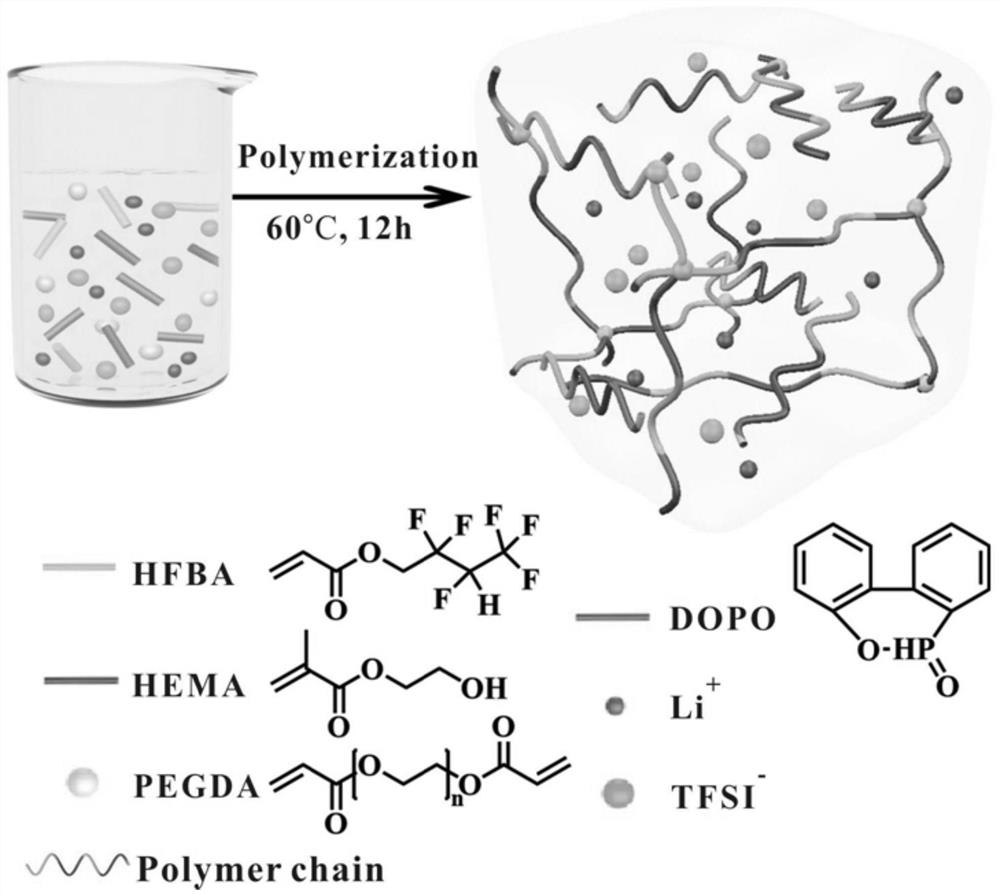

[0061] The preparation method of the flame retardant gel polymer electrolyte of the present invention comprises the following steps:

[0062] 1) Add hexafluorobutyl acrylate (HFBA) and hydroxyethyl methacrylate (HEMA) to the solvent. The solvent is an organic solvent such as DMF, acetonitrile, DMSO, etc., and the solvent consumption is preferably 50%-75%. Based on the total weight of the monomer and the solvent, the solvent accounts for between 50%-75% of the total weight. The amount of solvent has a great influence on the conductivity. In step 1), the molar ratio of HFBA and HEMA is greater than 2:1; its ratio can be very high or even close to infinity, such as the situation that the molar ratio of HFBA and HEMA is 1:0; more preferably, the molar ratio of HFBA and HEMA is ( 2-10): 1; more preferably, the molar ratio of HFBA to HEMA is 4-10:1 (including 4:1, 6:1, 8:1, 10:1). More preferably, the molar ratio of HFBA to HEMA is 8:1.

[0063] 2) Add flame retardant, polyethyle...

Embodiment 1

[0065] The preparation of embodiment 1 gel polymer electrolyte

[0066] HFBA (hexafluorobutyl acrylate) and HEMA (hydroxyethyl methacrylate) were added to the DMF solvent at a molar ratio of 6:1 (the mass ratio of monomer to solvent was 4:6). Then, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) at 1% by weight relative to the total mass of the monomers was added under stirring, relative to the total mass of the monomers 1.5% by weight polyethylene glycol diacrylate (PEGDA) and 2.5mol L -1 LiTFSI (4.306g) was added to the above solution. Finally, after addition of the initiator (2% AIBN relative to the total mass of monomers), the solution was transferred to a mold. After polymerization at 60 °C for 12 hours, the resulting gel polymer electrolyte (abbreviated as poly(HFBAx-co-HEMAy) was obtained.

Embodiment 2-8

[0067] Preparation of Example 2-8 Gel Polymer Electrolyte

[0068] HFBA and HEMA with different molar ratios (1:0, 10:1, 8:1, 6:1, 4:1, 2:1) were added to a 20 mL glass vial. The solvent consumption is between 50%-75%. Then, DOPO (1% by weight relative to the total mass of the monomer), PEGDA (1.5% by weight relative to the total mass of the monomer) and 0-3mol L -1 LiTFSI was added to the above solution. LiTFSI concentrations were controlled at 0.5, 1, 1.5, 2, 2.5, 3mol L -1 . Finally, after addition of the initiator (2% AIBN relative to the total mass of monomers), the solution was transferred to a mold. After polymerization at 50–80°C for 10–14 hours, the resulting gel polymer electrolyte (abbreviated as poly(HFBAx-co-HEMAy), where x and y represent the molar ratios of HFBA and HEMA, respectively, was obtained. For the reaction conditions, see Table 1.

[0069]Table 1 Preparation parameters of gel polymer electrolyte

[0070]

[0071] In a specific embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com