Antifreeze zwitterionic hydrogel electrolyte based on ion transition and Grotthuss transmission mechanism

An electrolyte and hydrogel technology, applied in the field of supercapacitors of antifreeze zwitterionic hydrogel electrolytes and their preparation, can solve the problems of loss of mechanical properties and electrical conductivity, no antifreeze properties, etc., and achieve good mechanical fatigue resistance. , the effect of good low temperature tolerance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

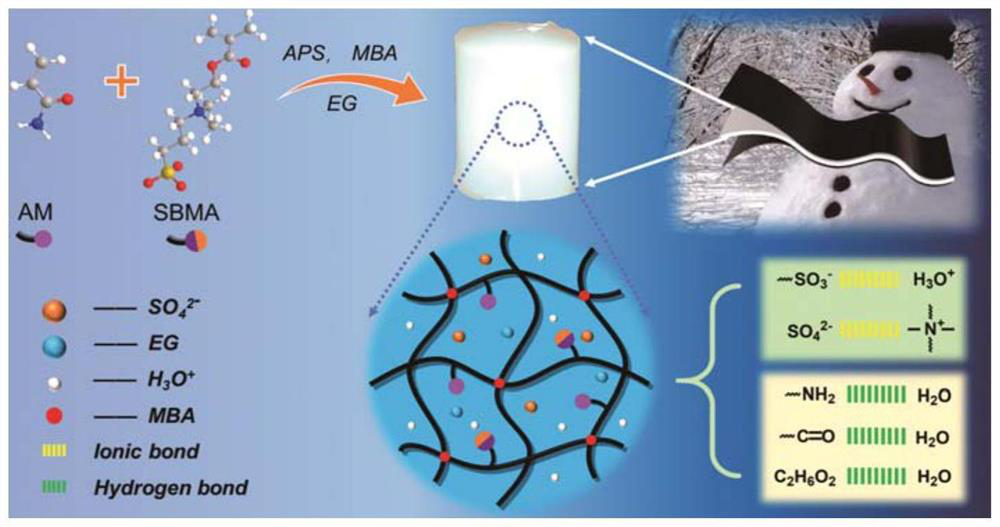

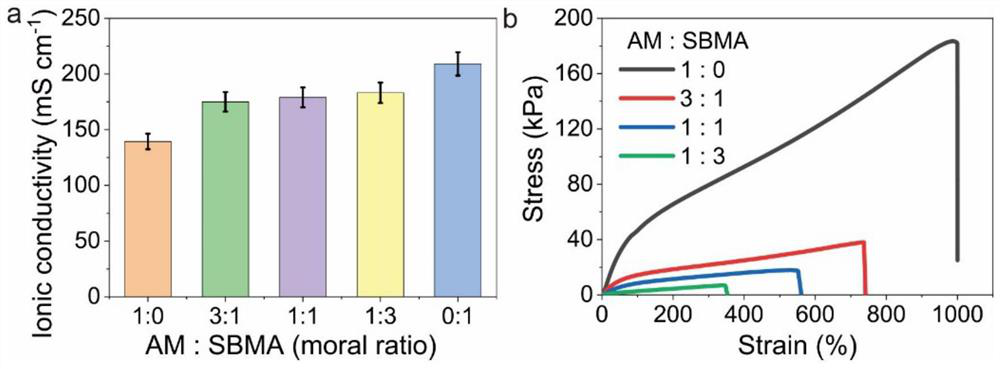

[0072] Example 1 Preparation of PolyAS hydrogel electrolyte and exploration of monomer ratio

[0073] The polyAS-EG gel electrolyte was obtained by random copolymerization of AM and SBMA. First, different molar ratios (1:0, 3:1, 1:1, 1:3, 0:1) of AM and SBMA (total mass: 2 g) were added to 5 ml of EG / H 2 O mixture, add 1MH 2 SO 4 and 0.2mg mL -1 MBA, then stirred in an ice bath for 1 hr. Subsequently, 0.02 g of the initiator APS (1 wt % relative to the total monomer mass) was added to the above solution, which was stirred under ice bath stirring for 30 minutes. Finally, the resulting precursor solution was sonicated for 10 minutes to remove air bubbles, the precursor solution was injected into a mold, sealed and polymerized at 45°C for 12 hours.

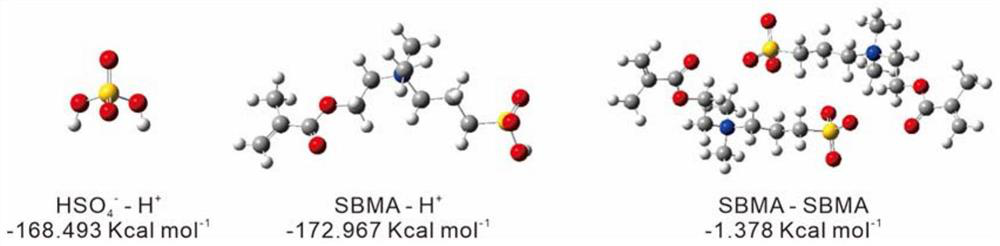

[0074] -SO in SBMA 3 - thought to promote proton conduction. First, density function theory (DFT) calculations were used to demonstrate the positive effect of SBMA on proton conductivity. Addition of H to poly(AM-SBMA) hydro...

Embodiment 2

[0080] Example 2 EG content and mechanical properties and antifreeze research

[0081] The polyzwitterionic hydrogel electrolyte was obtained by random copolymerization of AM and SBMA. First, according to the volume ratio of EG, the configuration contains 0%, 30%, 45%, 60% and 100% (volume concentration) of H 2 O / EG binary solvent system, then add MBA and sulfuric acid to the binary solvent system, and prepare the concentration of sulfuric acid to be 1 mol / L and the concentration of MBA to be 0.2 g / L. Then the monomer with a molar ratio of 3:1 (AM:SBMA) and a total mass of 2g (AM=0.866g, SBMA=1.134g) was added to the prepared binary solvent system (5ml), and the mixture was placed in an ice bath. Stir for 1 hour. Subsequently, under stirring in an ice bath, an initiator 0.02 g APS (1 wt% relative to the total monomer mass) was added to the above solution and stirring was continued for 30 min. Finally, the obtained precursor solution was sonicated for 10 min to remove air bu...

Embodiment 3

[0093] Example 3 PolyAS-EG 45 Conductivity Studies of Electrolytes

[0094] Using the antifreeze hydrogel electrolyte prepared in Example 2, the conductivity of electrolytes with different EG contents measured at different temperatures is as follows: Figure 7 a shown. With the increase of EG content, the conductivity of the electrolyte first increased and then decreased, mainly because the increase of EG content has a conductive effect on antifreeze, but too high EG content is not conducive to ion migration. polyAS-EG 45 Exhibits the highest ionic conductivity of 1.51 mS cm at -50 °C -1 (Table 1), is antifreeze 2M NaClO 4 / DMSO aqueous solution (0.11mS cm at -50°C -1 , Q.Nian,J.Wang,S.Liu,T.Sun,S.Zheng,Y.Zhang,Z.Tao,J.Chen,Angew.Chem.Int.Ed.2019,58,16994) ten times , further confirming the advantage of proton conduction. The ultra-low temperature conductivity of our hydrogel electrolyte is also the head level among the reported antifreeze hydrogel electrolytes, even th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com