Polyester material with high toughness and preparation method thereof

A polyester material and toughness technology, applied in the field of polyester material with strong toughness and its preparation, can solve the problem of low toughness of polyester, and achieve the effects of excellent strength, improved strength and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

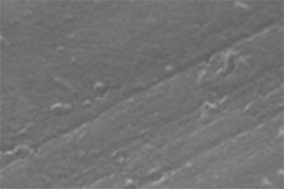

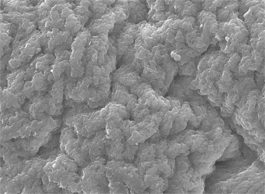

Image

Examples

preparation example Construction

[0020] A preparation method of a polyester material with strong toughness, the method at least comprises the following steps:

[0021] (1) Preparation of prepolymer: get L-tartaric acid, dihydromuconic acid, 1,7 heptanediol and dinonylnaphthalene sulfonic acid of the above-mentioned parts by weight, add them successively in the reactor containing carbon tetrachloride , introduce nitrogen, heat up to 166-170°C and stir for 30min, vacuumize and cool down to 120°C for 1-2h reaction, add the above-mentioned cyclohexyl isocyanate to the reaction kettle, and purify to obtain a prepolymer;

[0022] (2) Preparation of microcapsules: Microcapsules are prepared by spray cooling method;

[0023] (3) Blending: add the prepolymer and microcapsules into a stirring vessel for mixing, perform ultrasonic treatment on the vessel while stirring, mix for 20-30 min, and add the above-mentioned azobisisobutylene to the vessel. Nitrile, aromatic alcohol, auxiliary agent, and heat up to 100 °C, reac...

Embodiment 1

[0026] A tough polyester material, the material is composed of the following components in parts by weight: 10 parts of benzyl alcohol, 5 parts of cyclohexyl isocyanate, 5 parts of L-tartaric acid, 20 parts of dihydromuconic acid, 1,7 heptanedi 27 parts of alcohol, 1 part of dinonylnaphthalene sulfonic acid, 5 parts of microcapsules, 2 parts of azobisisobutyronitrile, 1 part of monoalkoxy fatty acid titanate, and 3 parts of silane coupling agent KH792; The wall material is polyethylene with a molecular weight of less than 10,000, the core material is a mixture of sodium alginate and nano-titanium dioxide, the diameter is about 30nm, the mass ratio of the two is 1:3, and the weight of the core material is 80% of the total weight of the microcapsules.

[0027] The preparation method of the tough polyester material comprises the following steps:

[0028] (1) Preparation of prepolymer: get L-tartaric acid, dihydromuconic acid, 1,7 heptanediol and dinonylnaphthalene sulfonic acid o...

Embodiment 2

[0033] A tough polyester material, the material is composed of the following components by weight: 20 parts of aryl alcohol, 6 parts of cyclohexyl isocyanate, 4 parts of L-tartaric acid, 16 parts of dihydromuconic acid, 1,7 parts of heptyl 22 parts of diols, 2 parts of dinonylnaphthalene sulfonic acid, 4 parts of microcapsules, 1 part of azobisisobutyronitrile, 0.5 parts of monoalkoxy fatty acid titanate, 1.5 parts of silane coupling agent KH570; microcapsules The wall material is polyethylene with a molecular weight of less than 10000, the core material is a mixture of sodium alginate and nano-titanium dioxide (30nm), the mass ratio of the two is 1:3, and the weight of the microcapsule core material is 80% of the total weight of the microcapsule;

[0034] The preparation method of the tough polyester material at least comprises the following steps:

[0035] (1) Preparation of prepolymer: get L-tartaric acid, dihydromuconic acid, 1,7 heptanediol and dinonylnaphthalene sulfonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com