Glass fiber reinforced plastic pipeline flange opening connecting structure

A connection structure, glass fiber reinforced plastic technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, pipe element, etc., can solve the problems of lengthening replacement cycle, easy rusting of connecting bolts, dust accumulation, limiting bolt removal method, etc. Guaranteed smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

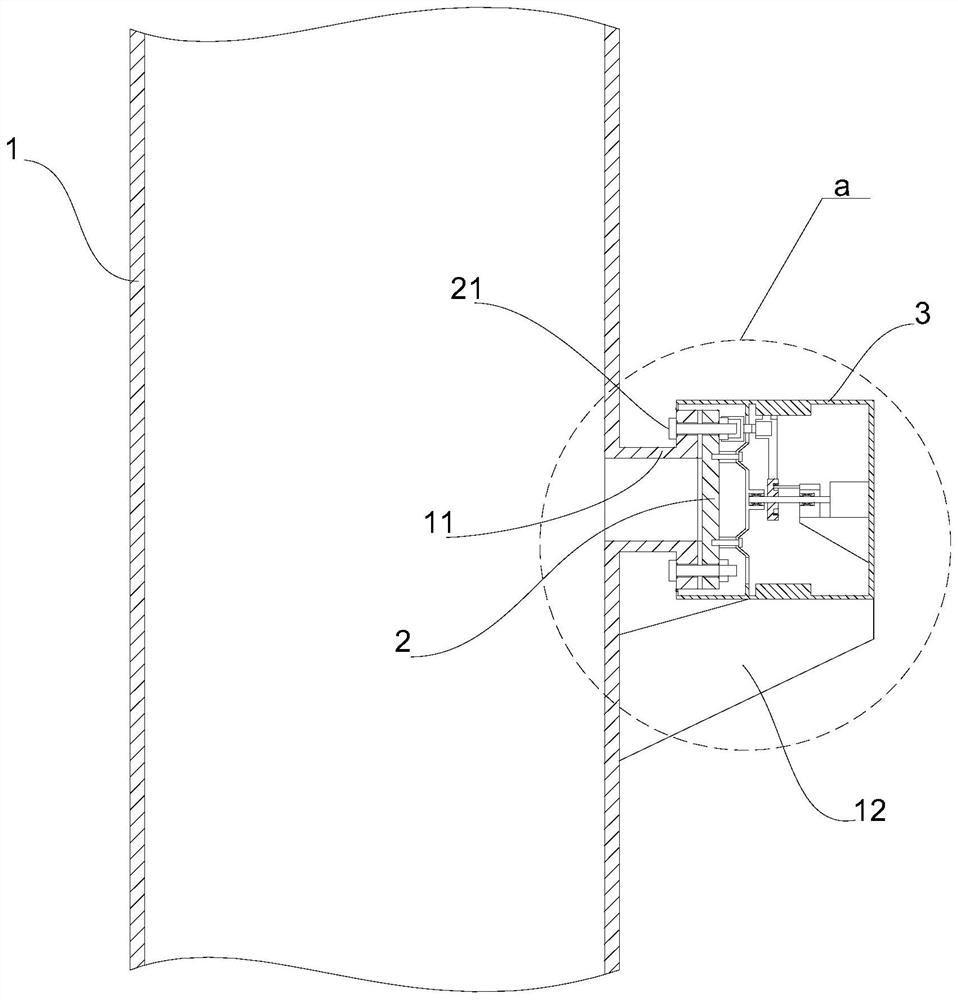

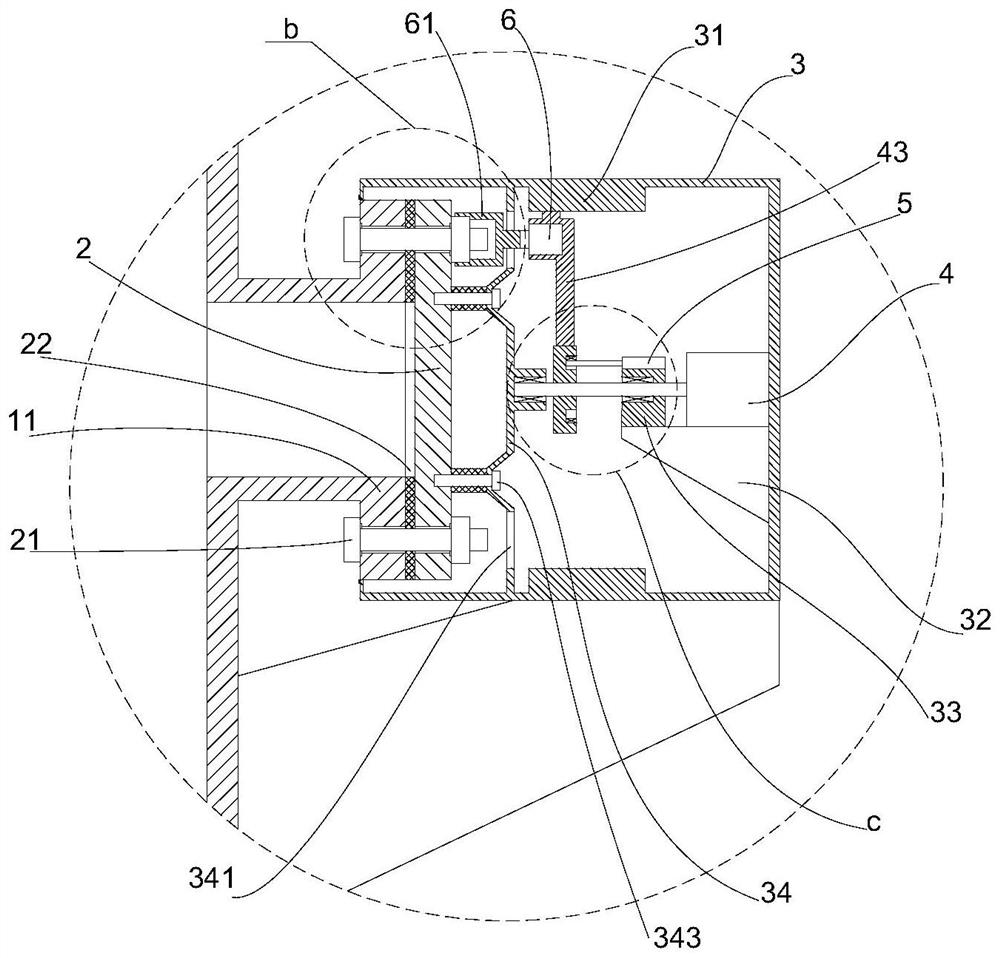

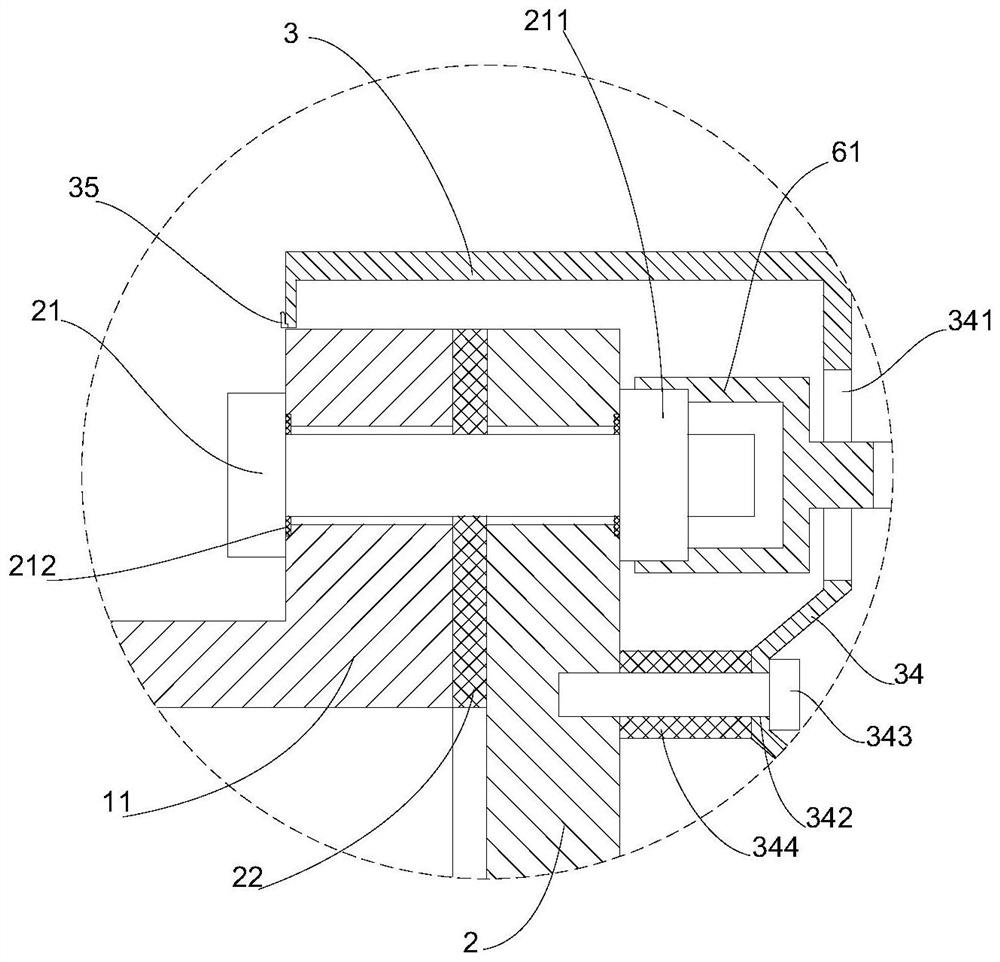

[0029] like Figures 1 to 5 As shown, a FRP pipe flange connection structure includes a pipe 1, a flange port 11 is provided on the pipe 1, and the flange port 11 and the cover body 2 are connected by a plurality of locking bolts 21.

[0030] A dust cover 3 is set on the periphery of the flange port 11, and the dust cover 3 can cover all the flange port 11 and the cover body 2. A mounting seat 12 is provided on the side wall of the pipe 1, and the cover body 2 is provided on the mounting seat 12. The dust cover 3 is divided into two cavities by an intermediate partition plate 34, the intermediate partition plate 34 and the cover body 2 are connected and fixed, and a nut tightening mechanism is arranged inside the dust cover 3.

[0031] The nut tightening mechanism includes a buckle head 61 , a tightening motor 6 , a telescopic cylinder 5 and an adjusting motor 4 . The rotating shaft 41 of the adjusting motor 4 is slidably provided with a turntable 42 . The axial sliding of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com