A motor rotor cooling system for an electric drive assembly

A motor rotor and cooling system technology, which is applied to the layout of the cooling combination of power plants, motors, electric vehicles, etc., can solve the problems of unfavorable integrated design of electric drive assembly, small heat exchange area of coolant, and insufficient cooling effect , to achieve the effect of reducing the structural mass, ensuring the cooling effect, and reducing the mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

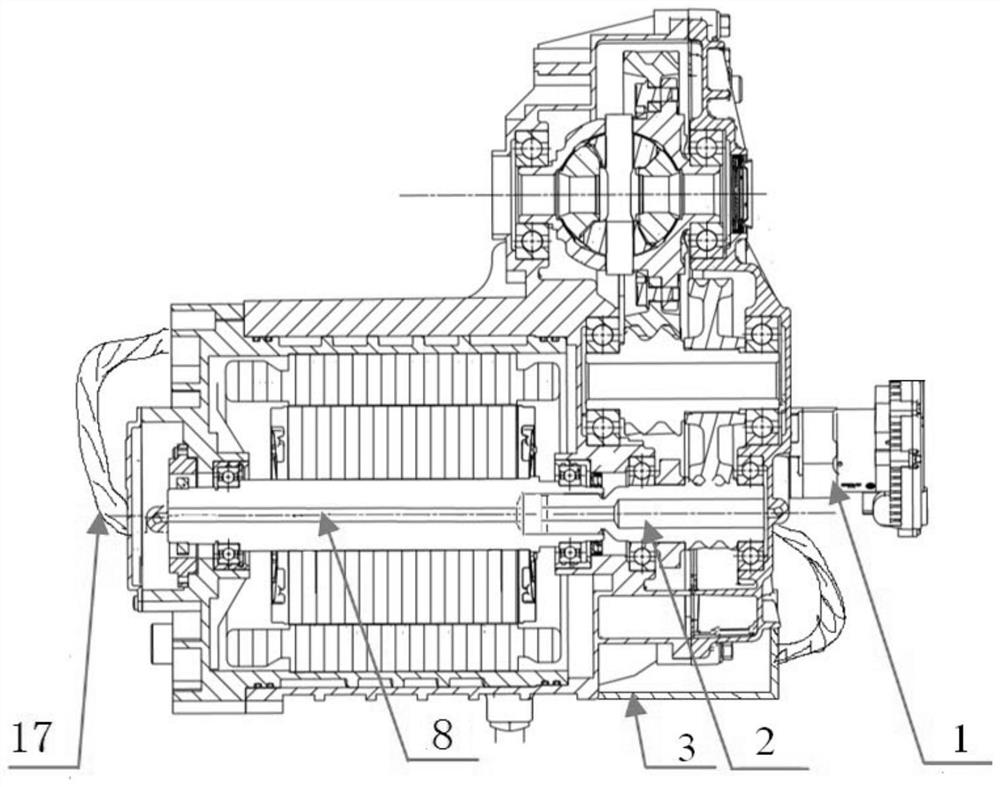

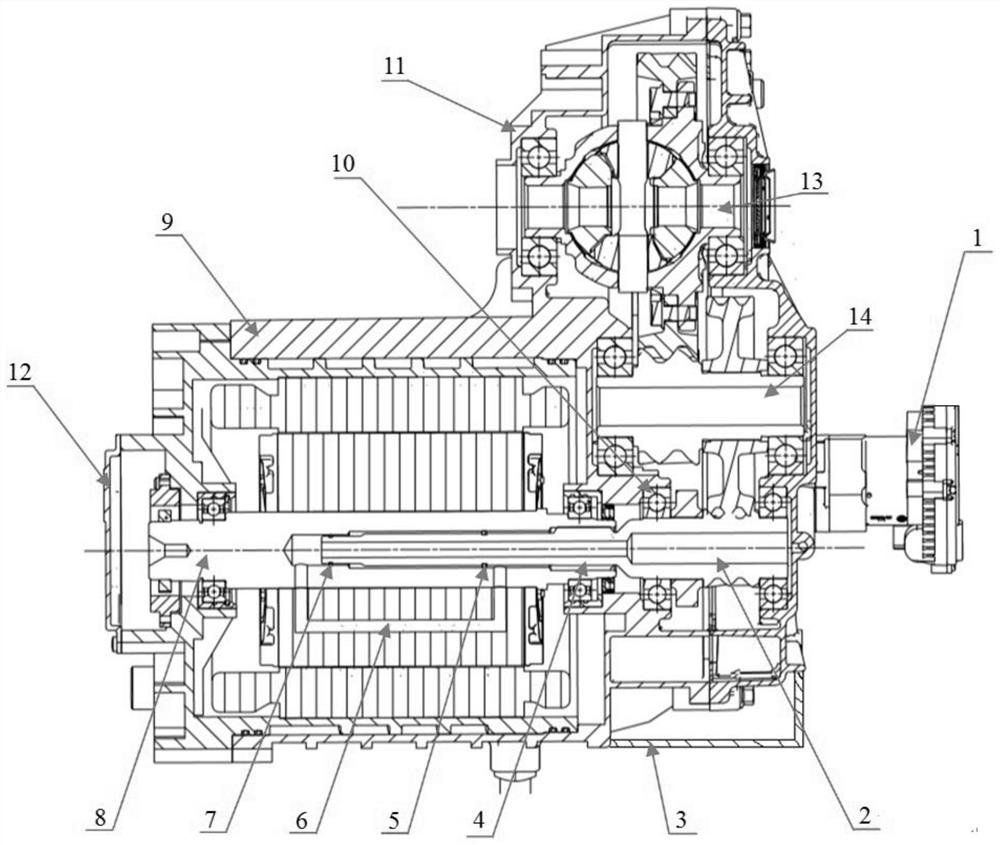

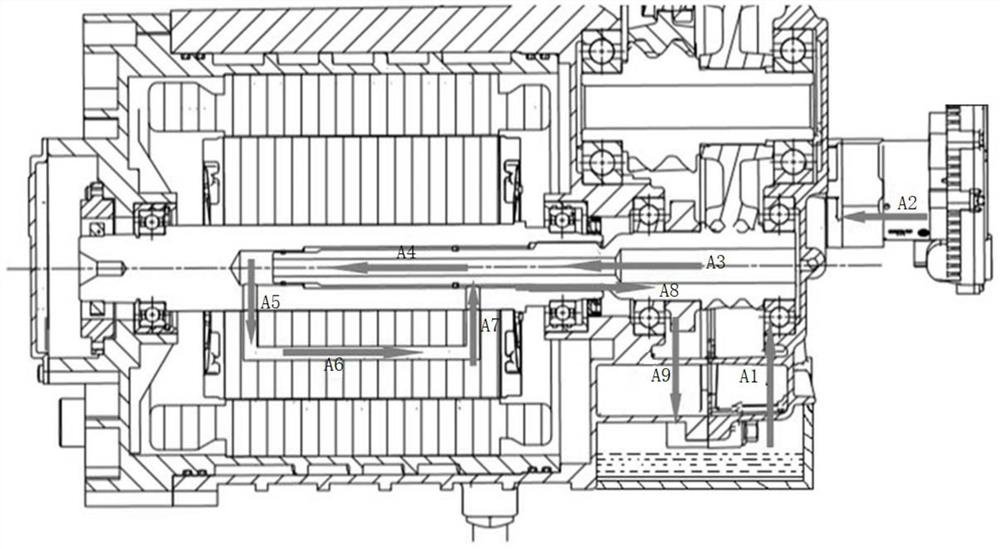

[0023] According to the following Figure 2 to Figure 5 The specific embodiments of the present invention are further described:

[0024] This embodiment provides a motor rotor cooling system for an electric drive assembly, such as figure 2 As shown, including pump 1, oil pan 3, motor rotor, reducer hollow input shaft 2, motor housing 9, bearing 10 at the front end of reducer hollow input shaft 2, bearing 10 at the rear end of reducer hollow input shaft 2, reducer Housing 11 , motor rear housing 12 , reducer differential assembly 13 , reducer intermediate shaft assembly 14 .

[0025] like figure 2 As shown, the motor rotor of this embodiment includes a motor rotor lamination core and a motor hollow shaft 8 fixed inside the motor rotor lamination core. The oil suction port of the pump 1 is immersed in the oil pan 3, and the pump 1 The oil outlet is sealed with one end of the hollow input shaft 2 of the reducer, the other end of the hollow input shaft 2 of the reducer is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com