A manufacturing method to solve the mass production of electromagnetic shielding type rigid-flex board

A rigid-flex technology, high-volume board technology, applied in the reduction of crosstalk/noise/electromagnetic interference (, printed circuit manufacturing, multi-layer circuit manufacturing, etc., can solve the feasibility of mass production and high fixture cost , PET protective film scrapped and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

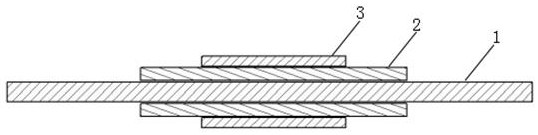

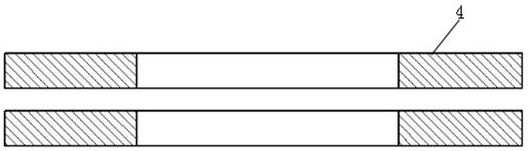

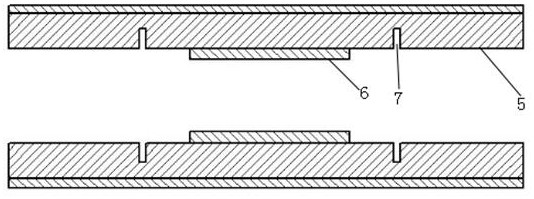

[0027] refer to Figure 1-Figure 5 , a manufacturing method of the present invention that solves the mass production of electromagnetic shielding type rigid-flex boards, comprising a flexible core board manufacturing step, a low-flow prepreg manufacturing step, a rigid core board manufacturing step, a lamination press synthesis step, and a cover removal step . Wherein, the manufacturing step of the rigid core board includes: setting a protective film 6 on the uncovered area of the rigid core board 5 . In the laminate lamination step, the protective film 6 completely covers the electromagnetic wave shielding film 3 on the flexible core board 1 . Because the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com