Wear-resistant shoe outsole and preparation method thereof

A technology of shoe outsole and wear-resistant layer, which is applied in the field of wear-resistant shoe outsole and its preparation, can solve the problems of heavy weight, short service life and heavy load on the foot of rubber soles, so as to improve wear resistance and wear resistance Good performance and small average gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of wear-resistant shoe outsole, comprising the following steps:

[0023] Step 1, prepare the wear-resistant layer: A. First mix and stir the raw materials except glycerol monostearate, methyl propylene glycol, and dicumyl peroxide, and then add glycerol monostearate, methyl propylene glycol, Dicumyl peroxide is mixed evenly, then kneaded by a calender, and formed into rubber granules through kneading, sheeting, extrusion and granulation; B. According to the vulcanization and foaming parameters, the rubber granules are directly molded in the shoe mold Molding, molding temperature 130-140 ℃, molding time 20-30min;

[0024] Step 2, prepare the midsole: first mix ethylene-vinyl acetate copolymer, talc, zinc oxide, bamboo fiber, triethylenediamine, calcium stearate, and ethylenediamine evenly, add azodicarbonamide, hard Fatty acid is rolled with a roll, and then cross-linking agent is added for mixing, and the sheet is cut out, placed in a mold, hot-pre...

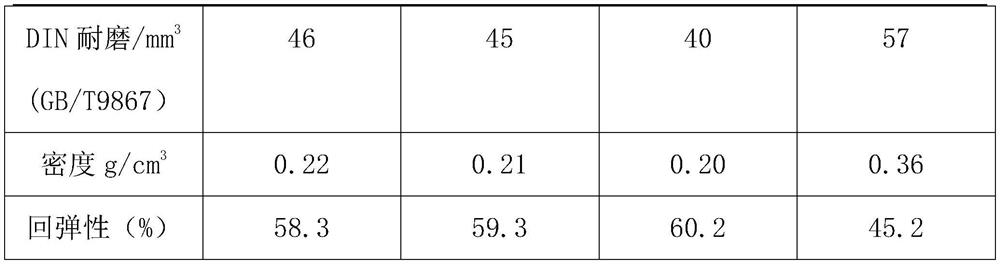

Embodiment 1

[0027] A wear-resistant shoe outsole comprises a wear-resistant layer and a midsole compounded on the wear-resistant layer.

[0028] The wear-resistant layer is composed of the following raw materials by weight: 50 parts of styrene-butadiene rubber, 30 parts of natural rubber, 30 parts of bromobutyl rubber, 12 parts of glycerol monostearate, 8 parts of methyl propylene glycol, and diisopropyl peroxide 10 parts of benzene, 5 parts of polyethylene glycol, 10 parts of modified glass fiber, 10 parts of polydimethylsiloxane, 3 parts of polyethylene wax, 8 parts of modified bentonite, and 1 part of calcium stearate.

[0029] The midsole is composed of the following raw materials by weight: 70 parts of ethylene-vinyl acetate copolymer, 18 parts of talcum powder, 3 parts of zinc oxide, 5 parts of bamboo fiber, 2.5 parts of azodicarbonamide, 1.8 parts of benzoyl peroxide , 0.5 parts of stearic acid, 0.6 parts of triethylenediamine, 1.5 parts of calcium stearate, and 2 parts of ethylene...

Embodiment 2

[0035] A wear-resistant shoe outsole comprises a wear-resistant layer and a midsole compounded on the wear-resistant layer.

[0036] The wear-resistant layer is composed of the following raw materials by weight: 70 parts of styrene-butadiene rubber, 20 parts of natural rubber, 40 parts of bromobutyl rubber, 5 parts of glycerol monostearate, 15 parts of methyl propylene glycol, and diisopropyl peroxide 12 parts of benzene, 3 parts of polyethylene glycol, 15 parts of modified glass fiber, 5 parts of polydimethylsiloxane, 6 parts of polyethylene wax, 5 parts of modified bentonite, and 2 parts of calcium stearate.

[0037] The midsole is composed of the following raw materials by weight: 80 parts of ethylene-vinyl acetate copolymer, 12 parts of talcum powder, 10 parts of zinc oxide, 3 parts of bamboo fiber, 4.2 parts of azodicarbonamide, 2.7 parts of benzoyl peroxide , 0.3 parts of stearic acid, 1.2 parts of triethylene diamine, 2.5 parts of calcium stearate, and 1 part of ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com