Polytetrafluoroethylene flexible copper-clad plate containing glass fabric and preparation method thereof

A technology of polytetrafluoroethylene and flexible copper-clad laminates, which is applied in the direction of chemical instruments and methods, other household appliances, glass/slag layered products, etc., and can solve the problem of discounting dielectric properties, low cohesive energy, and glass fiber cloth mesh Small size and other problems, to achieve the effect of reducing the reduction of the overall thickness, saving energy and equipment, and large pressing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

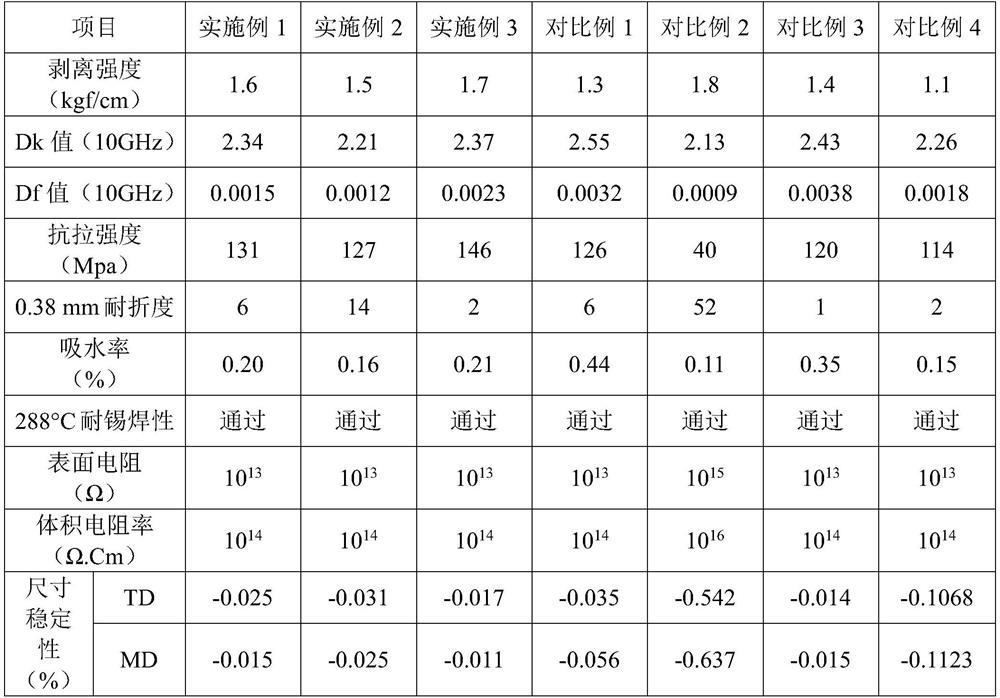

Examples

Embodiment 1

[0046] A polytetrafluoroethylene flexible copper clad laminate containing glass fiber cloth, the structure of the polytetrafluoroethylene flexible copper clad laminate containing glass fiber cloth, from top to bottom, sequentially includes an upper copper foil layer, an upper fusible polytetrafluoroethylene Vinyl layer, upper mixed layer, glass fiber cloth layer, lower mixed layer, lower fusible PTFE layer and lower copper foil layer;

[0047] in,

[0048] The upper mixed layer and the lower mixed layer are prepared by blending polytetrafluoroethylene and fusible polytetrafluoroethylene;

[0049] In the mixed layer, the mass ratio of polytetrafluoroethylene and fusible polytetrafluoroethylene is 20:80;

[0050] The glass fiber cloth has a grid structure;

[0051] The size of the grid is 0.8mm;

[0052] The thickness of the upper mixed layer and the lower mixed layer is 10 μm;

[0053] The thickness of the upper fusible PTFE layer and the lower fusible PTFE layer is 30 μm; ...

Embodiment 2

[0062] A polytetrafluoroethylene flexible copper clad laminate containing glass fiber cloth, the structure of the polytetrafluoroethylene flexible copper clad laminate containing glass fiber cloth, from top to bottom, sequentially includes an upper copper foil layer, an upper fusible polytetrafluoroethylene Vinyl layer, upper mixed layer, glass fiber cloth layer, lower mixed layer, lower fusible PTFE layer and lower copper foil layer;

[0063] in,

[0064] The upper mixed layer and the lower mixed layer are prepared by blending polytetrafluoroethylene and fusible polytetrafluoroethylene;

[0065] In the mixed layer, the mass ratio of polytetrafluoroethylene and fusible polytetrafluoroethylene is 25:80;

[0066] The glass fiber cloth has a grid structure;

[0067] The size of the grid is 0.8mm;

[0068] The thickness of the upper mixed layer and the lower mixed layer is 10 μm;

[0069] The thickness of the upper fusible PTFE layer and the lower fusible PTFE layer is 35 μm; ...

Embodiment 3

[0076] A polytetrafluoroethylene flexible copper clad laminate containing glass fiber cloth, the structure of the polytetrafluoroethylene flexible copper clad laminate containing glass fiber cloth, from top to bottom, sequentially includes an upper copper foil layer, an upper fusible polytetrafluoroethylene Vinyl layer, upper mixed layer, glass fiber cloth layer, lower mixed layer, lower fusible PTFE layer and lower copper foil layer;

[0077] in,

[0078] The upper mixed layer and the lower mixed layer are prepared by blending polytetrafluoroethylene and fusible polytetrafluoroethylene;

[0079] In the mixed layer, the mass ratio of polytetrafluoroethylene and fusible polytetrafluoroethylene is 30:80;

[0080] The glass fiber cloth has a grid structure;

[0081] The size of the grid is 0.8mm;

[0082] The thickness of the upper mixed layer and the lower mixed layer is 10 μm;

[0083] The thickness of the upper fusible PTFE layer and the lower fusible PTFE layer is 25 μm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com