Petroleum machinery winch cable tension intelligent control method

A petroleum machinery and intelligent control technology, applied in the direction of mechanical pressure/force control, adaptive control, general control system, etc., can solve the problems of error uncertainty, easy oscillation, single parameter, etc., to eliminate transmission error and friction High precision of torque and control, and the effect of reducing the number of iterations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

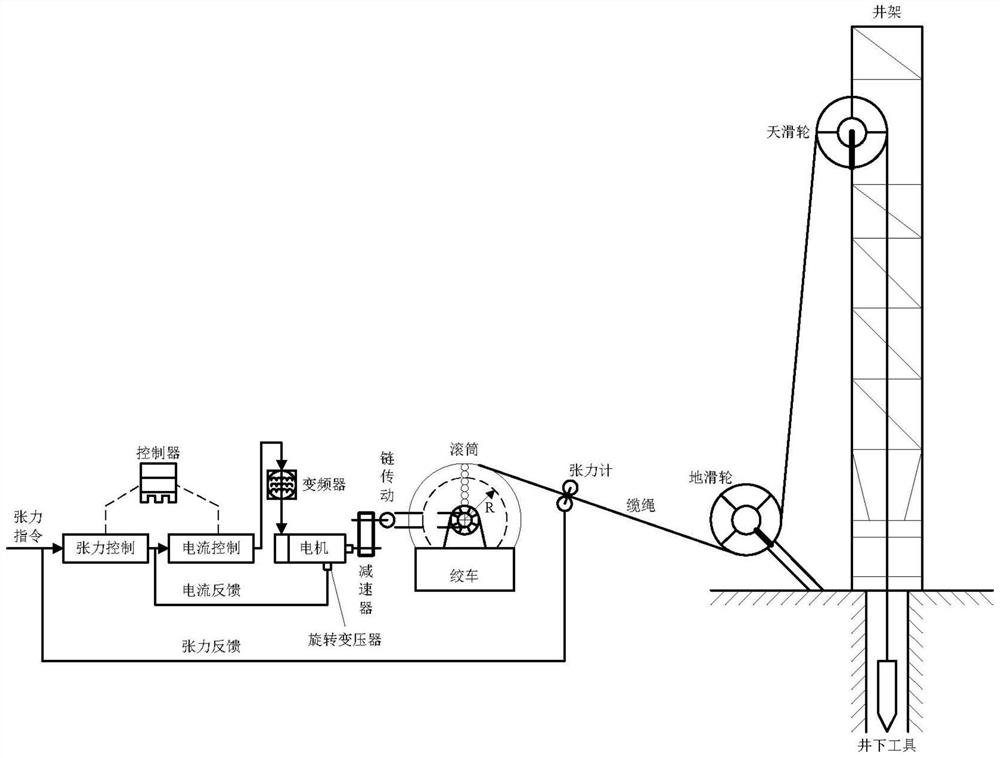

[0024] An intelligent control method for the cable tension of a petroleum machinery winch in this embodiment 1, combined with figure 1 Examples of the present invention will be described.

[0025] For the 7000-meter electric drive logging vehicle as the object, as shown in the attached figure 1 As shown in the figure, the fuzzy PID control algorithm is written into the S7-1200 CPU in the form of PLC language, and the tension signal of the tensiometer is transmitted to the PLC for self-adaptive PID parameter setting. Automatic control process.

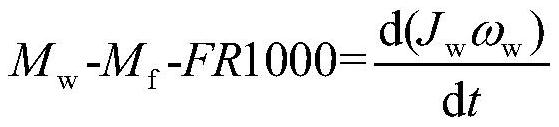

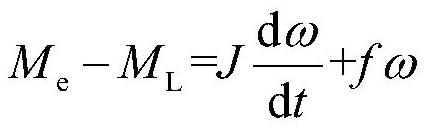

[0026] For the closed-loop control of the tension of the cable winch, it is first necessary to establish a mathematical model of the tension PID control. If the cable is in the lifting state, the real-time radius after the cable is wound around the drum is R, and the angular velocity of the winch drum is ω w , the cable tension is F, and the winch driving torque M w , the viscous friction torque M of the winch drum f , J w It is t...

Embodiment 2

[0049] The difference between this implementation and Example 1 is that, in order to describe the cable tension nonlinear control system, improve the stability, and have better generalization ability, the neural network is combined with the PID controller, and the self-learning of the neural network is fully utilized. Ability to continuously self-learn and self-tune the adjustable parameters of the PID controller, so as to independently find the best combination that can optimize the control performance of the PID controller. The details are as follows:

[0050] Taking into account the operating efficiency and control performance requirements of the tension control system, the "4-5-3" three-layer BP neural network structure is adopted, that is, the input layer is 4 neural nodes, the hidden layer is 5 neural nodes, and the output layer is 3 neural nodes. The learning algorithm uses the gradient descent method to continuously update the weights between layers through error backp...

Embodiment 3

[0055] The difference between this implementation and Example 1 and Example 2 is that, in order to combine the advantages of fuzzy logic and neural network control, the fuzzy system has the learning ability and the physical meaning of each node of the neural network is clear. The knowledge of tension approximate dynamics model and manual debugging experience are used to construct the framework to speed up the learning process. The self-learning ability of the fuzzy neural network can be used to correct the adjustable parameters of the PID online. The details are as follows:

[0056] Fuzzy logic has a set of rule bases based on expert experience, which can express knowledge with fewer rules; neural network has strong learning ability and parallel processing ability, and can generate rules without expressing knowledge. And both can be applied to the system where the input-output relationship is a nonlinear mapping. The FNN-PID controller is composed of a fuzzy neural network and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com