Glass strengthening liquid as well as preparation method and application thereof

A glass strengthening and glass technology, which is applied in the field of glass strengthening, can solve the problems of small increase in glass impact strength, adverse effects on the health of workers, and scratches, etc., to eliminate or passivate micro-cracks, reduce the proportion of scratches, and reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The present invention also provides the above-mentioned preparation method of glass strengthening liquid, comprising the following steps:

[0073] The alkaline agent, surfactant, chelating agent, auxiliary agent and water are mixed.

[0074] In one embodiment, the preparation method of described glass strengthening liquid, comprises the steps:

[0075] According to the ratio, take 10% to 40% of the target water mass, add alkaline reagent first, stir to dissolve, cool down to 40 °C, add auxiliary, chelating agent, surfactant and the remaining amount of water in turn, stir evenly Afterwards, a glass strengthening liquid is obtained.

[0076] The present invention also provides the application of the glass strengthening liquid as described above. The technical solution is as follows:

[0077] A glass strengthening method, comprising the steps of:

[0078] Pretreating the glass, and then contacting the pretreated glass with the above-mentioned glass strengthening liquid...

Embodiment 1

[0087] This embodiment provides a glass strengthening liquid and a preparation method and application thereof.

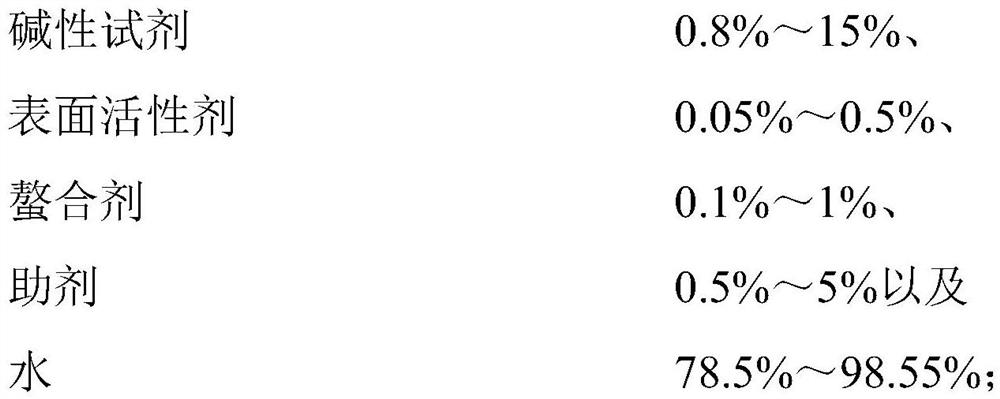

[0088] (1) In terms of mass percentage, the composition of the glass strengthening liquid of the present embodiment is as follows:

[0089]

[0090] (2) the preparation method of the glass strengthening liquid of the present embodiment is as follows:

[0091] Take water that accounts for 20% of the target water mass, add sodium hydroxide first, stir to dissolve, cool down to 40 ° C, add glycerol, sodium gluconate, OEP-98, fast penetrant T and the remaining amount of water in turn, stir evenly to obtain Glass strengthening fluid.

[0092] (3) The steps of the strengthening method of the glass provided by the present embodiment are as follows:

[0093] The glass is subjected to cutting and CNC processing, polishing treatment and tempering treatment in sequence, and then the tempered glass is immersed in a glass strengthening solution with a temperature of 70 ° C ...

Embodiment 2

[0095] This embodiment provides a glass strengthening liquid and a preparation method and application thereof.

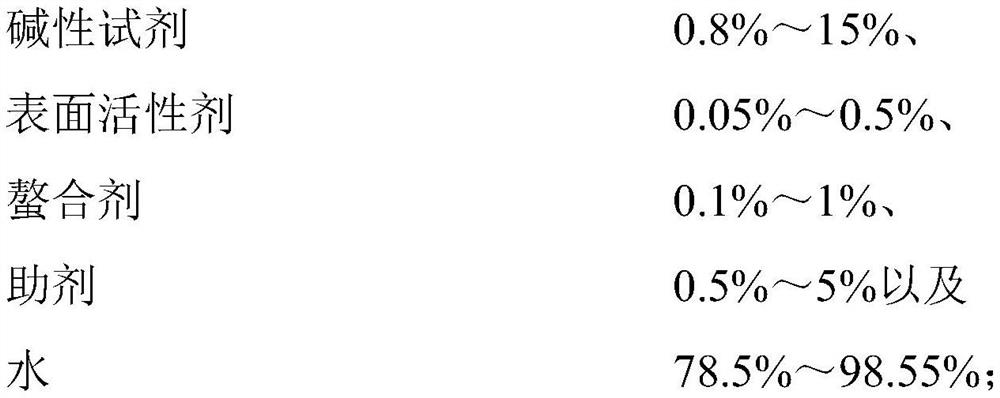

[0096] (1) In terms of mass percentage, the composition of the glass strengthening liquid of the present embodiment is as follows:

[0097]

[0098] (2) the preparation method of the glass strengthening liquid of the present embodiment is as follows:

[0099] Take water that accounts for 20% of the target water mass, add sodium hydroxide first, stir to dissolve, cool down to 40 ° C, add glycerol, sodium gluconate, OEP-98, fast penetrant T and the remaining amount of water in turn, stir evenly to obtain Glass strengthening fluid.

[0100] (3) The steps of the strengthening method of the glass provided by the present embodiment are as follows:

[0101] The glass is subjected to cutting and CNC processing, polishing treatment and tempering treatment in sequence, and then the tempered glass is immersed in a glass strengthening solution with a temperature of 70 ° C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com