Graphite-based powder metallurgy material for drilling lock and preparation method of graphite-based powder metallurgy material

A powder metallurgy and powder material technology is applied in the field of powder metallurgy to prepare easy-drilling graphite-based lock body materials. Processability, improving density and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

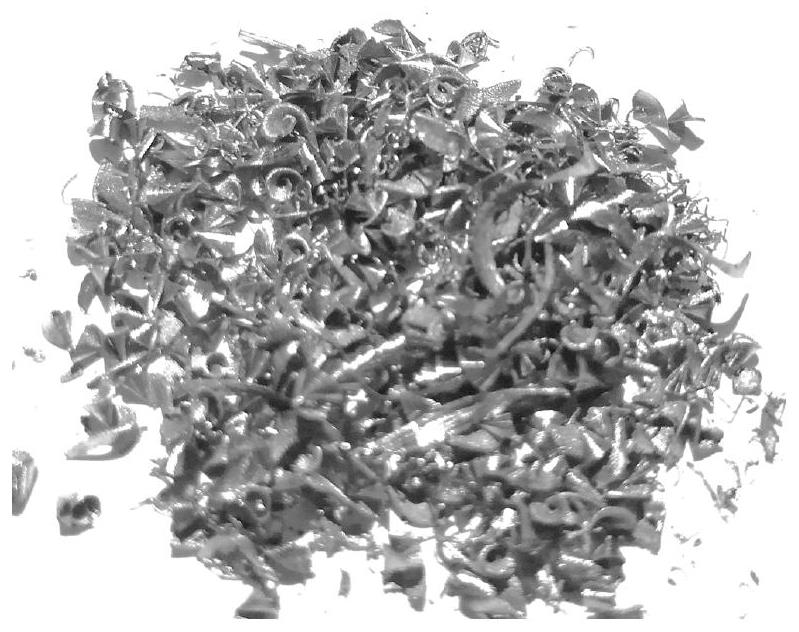

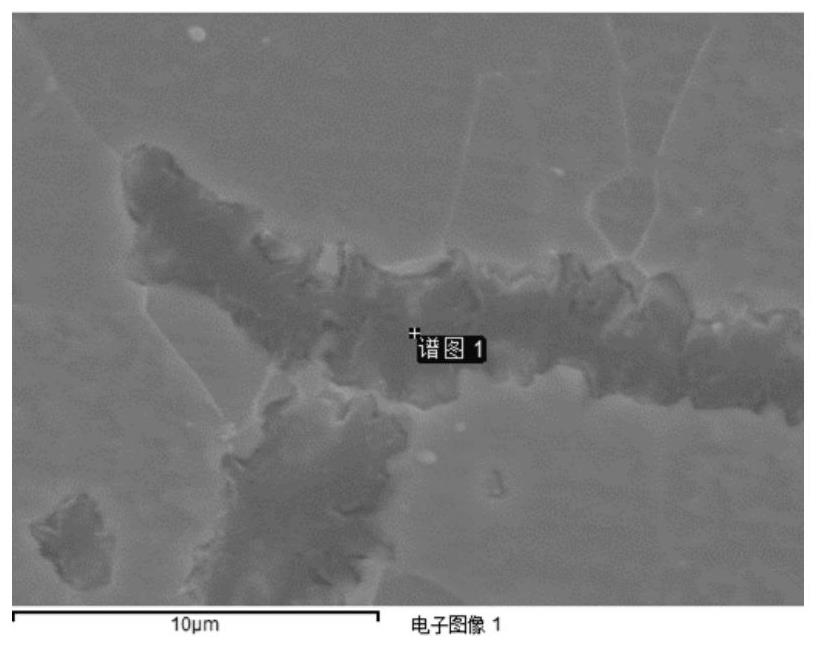

[0039] A method for preparing easy-drilling graphite-based lock materials by powder metallurgy in this embodiment is carried out according to the following steps: 959kg of iron blocks, 3kg of silicon particles, and 18kg of aluminum particles are heated and melted in a medium frequency induction furnace to 1550° C. and then injected into high-pressure mist. In the atomizing tower (the pressure of atomized argon gas and the diameter of the nozzle are 1.5MPa and 1.5mm respectively), atomized and condensed into pre-alloyed Fe-Si-Al powder material, and then sieved with a mesh to obtain Fe-Si with 250-300 meshes -Al sintering raw material; mix 98 parts of 250-300 mesh Fe-Si-Al sintering raw material and 2 parts of 500-600 mesh graphite powder in a mixer for 30 minutes at a speed of 30 r / min, and then add 0.8 part of a binder The solution (the ratio of binder and acetone is 1:10) is bonded, dried after bonding for 10 minutes, and then 0.2 parts of lubricant is added and mixed for 45 ...

Embodiment 2

[0041] A method for preparing easy-drilling graphite-based lock materials by powder metallurgy in this embodiment is carried out according to the following steps: 965kg of iron blocks, 2kg of silicon particles, and 15kg of aluminum particles are heated and melted in a medium frequency induction furnace to 1580° C. and then injected into high-pressure mist. In the atomizing tower (the pressure of atomized argon gas and the diameter of the nozzle are 1.5MPa and 1.5mm respectively), atomized and condensed into pre-alloyed Fe-Si-Al powder material, and then sieved with a mesh to obtain Fe-Si with 250-300 meshes -Al sintering raw material; mix 98.2 parts of 250-300 mesh Fe-Si-Al sintering raw material and 1.8 parts of 500-600 mesh graphite powder in a mixer for 25 minutes at a speed of 25 r / min, and then add 1.2 parts of binder The solution (the ratio of binder and acetone is 1:9) is bonded, dried for 8 minutes, then 0.5 part of lubricant is added and mixed for 40 minutes at a speed...

Embodiment 3

[0043] A method for preparing easy-drilling graphite-based lock materials by powder metallurgy in this embodiment is carried out according to the following steps: 971kg iron blocks, 1kg silicon particles, and 13kg aluminum particles are heated and melted in a medium frequency induction furnace to 1600° C. and then injected into high-pressure mist. In the atomizing tower (the pressure of atomized argon gas and the diameter of the nozzle are 1.5MPa and 1.5mm respectively), atomized and condensed into pre-alloyed Fe-Si-Al powder material, and then sieved with a mesh to obtain Fe-Si with 250-300 meshes -Al sintering raw material; mix 98.5 parts of 250-300 mesh Fe-Si-Al sintering raw material and 1.5 parts of 500-600 mesh graphite powder in a mixer for 35 minutes at a speed of 35 r / min, and then add 1.0 part of a binder The solution (the ratio of binder and acetone is 1:8) is bonded, dried after bonding for 15 minutes, then 0.3 parts of lubricant is added and the secondary mixing is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com