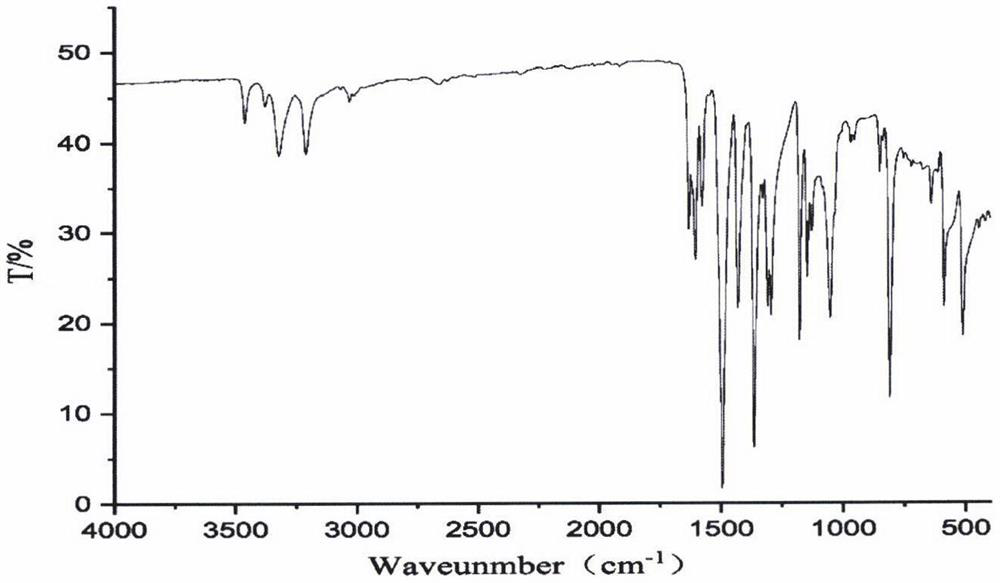

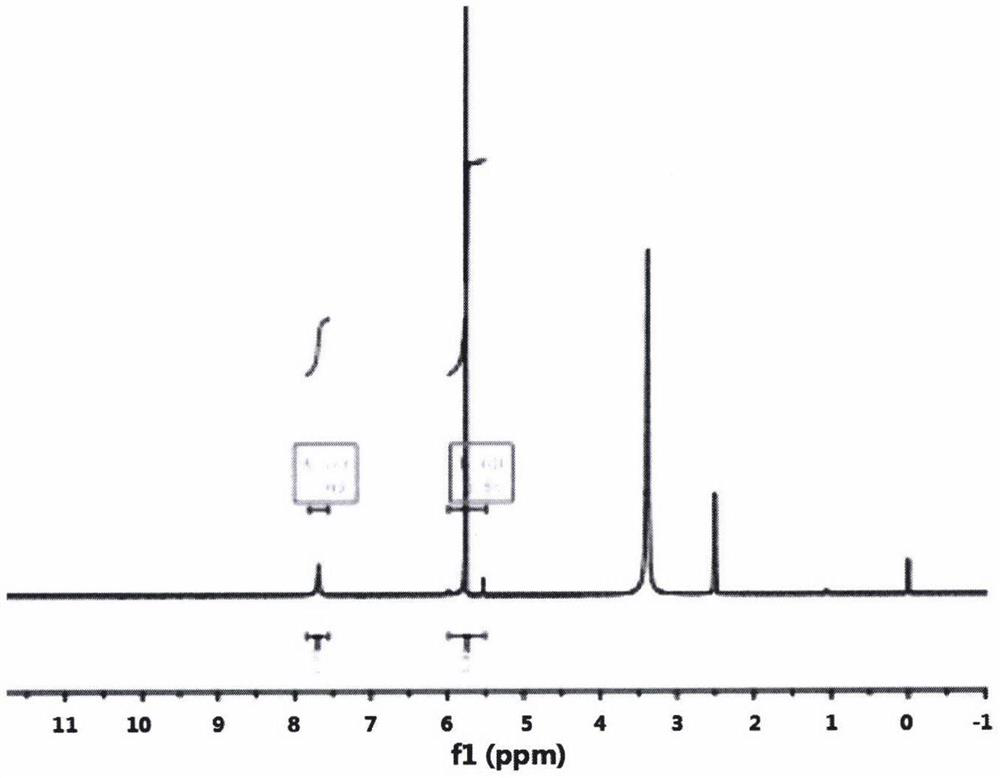

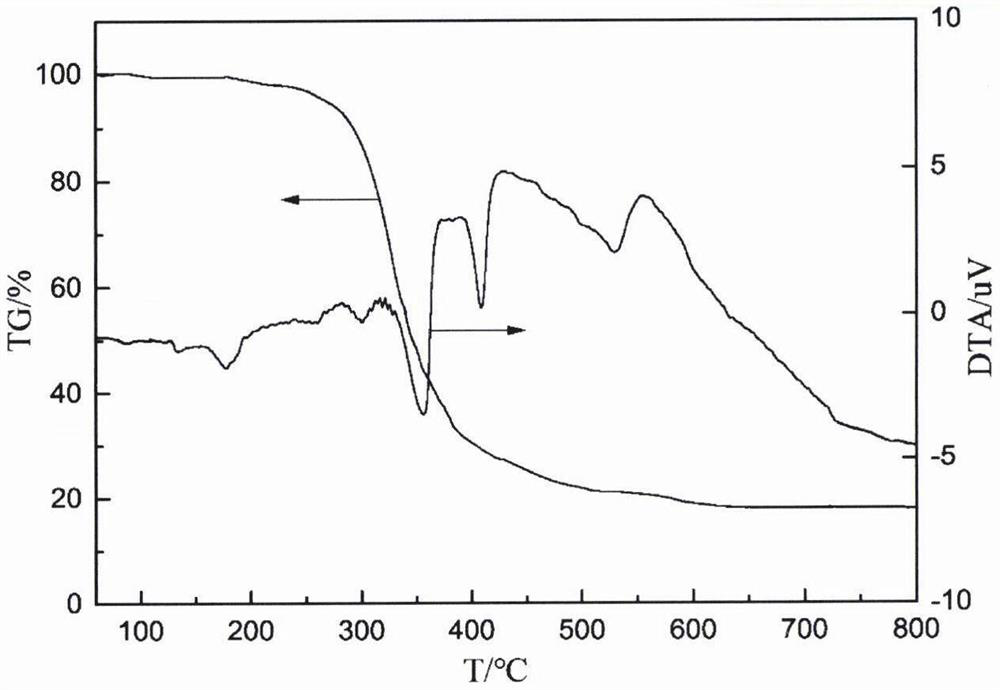

Flame retardant phosphoryl melamine compound and preparation method thereof

A technology of flame retardant phosphoramidide and phosphoramidide, which is applied in the field of flame retardant phosphoramidine compound and its preparation, can solve the problems of poor permanence, easy migration, easy blooming, etc., and achieve structural stability Good, easy to obtain raw materials, good anti-melt dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 In a 500mL four-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a drying tube, under nitrogen protection, add dry melamine sodium salt 29.62g (0.2mol) and 150mL of chloroform, within 30 minutes at room temperature. 30.66g (17.1mL, 0.2mol) of phosphorus oxychloride was added dropwise, after dropping, the temperature was raised to 60°C, refluxed for 6 hours, 3.6mL of water was added dropwise, the reaction was performed for 1 hour until no hydrogen chloride gas was generated, and the temperature was lowered to 30°C, Then add 18 mL of water to dissolve the sodium chloride, suction filtration, rinse the filter cake three times with 60 mL of ice water, compact and drain for each rinse, and vacuum dry at 80 °C to obtain white crystal phosphoramide. . The product yield was 88.3%.

Embodiment 2

[0031] Embodiment 2 In a 500mL four-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a drying tube, under nitrogen protection, add dry melamine sodium salt 29.62g (0.2mol) and 180mL of dichloroethane, at room temperature 30.66g (17.1mL, 0.2mol) of phosphorus oxychloride was added dropwise within 30 minutes, after the drop was completed, the temperature was raised to 80°C, the reaction was refluxed for 6 hours, 3.6mL of water was added dropwise, the reaction was performed for 1 hour until no hydrogen chloride gas was generated, and the temperature was cooled to 30 ℃, then add 18 mL of water to dissolve the generated sodium chloride, suction filtration, the filter cake is rinsed three times with 60 mL of ice water, each rinse is compacted and drained, and dried at 80 ℃ in vacuum to obtain white crystalline phosphorus amide. The product yield was 90.5%.

Embodiment 3

[0032] Embodiment 3 In the 500mL four-necked flask equipped with agitator, thermometer, reflux condenser and drying tube, under nitrogen protection, add dry melamine sodium salt 29.62g (0.2mol) and 180mL carbon tetrachloride, at room temperature 30.66g (17.1mL, 0.2mol) of phosphorus oxychloride was added dropwise within 30 minutes, after dropping, the temperature was raised to 75°C, refluxed for 5 hours, 3.6mL of water was added dropwise, the reaction was performed for 1 hour until no hydrogen chloride gas was produced, and the temperature was cooled to 30 ℃, then add 18 mL of water to dissolve the generated sodium chloride, suction filtration, the filter cake is rinsed three times with 60 mL of ice water, each rinse is compacted and drained, and dried at 80 ℃ in vacuum to obtain white crystalline phosphorus amide. The product yield was 86.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com