LATP composite positive plate with low interface internal resistance, preparation method and all-solid-state lithium ion battery

A technology of composite positive electrode and positive electrode sheet, applied in the direction of positive electrode, battery electrode, secondary battery, etc., can solve the problem of affecting the electrochemical performance and cycle life of solid lithium battery, irreversible decomposition of inorganic solid electrolyte, reducing solid interface layer resistance, etc. The problem is to shorten the sintering time, improve the electrochemical performance and cycle life, and reduce the sintering temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

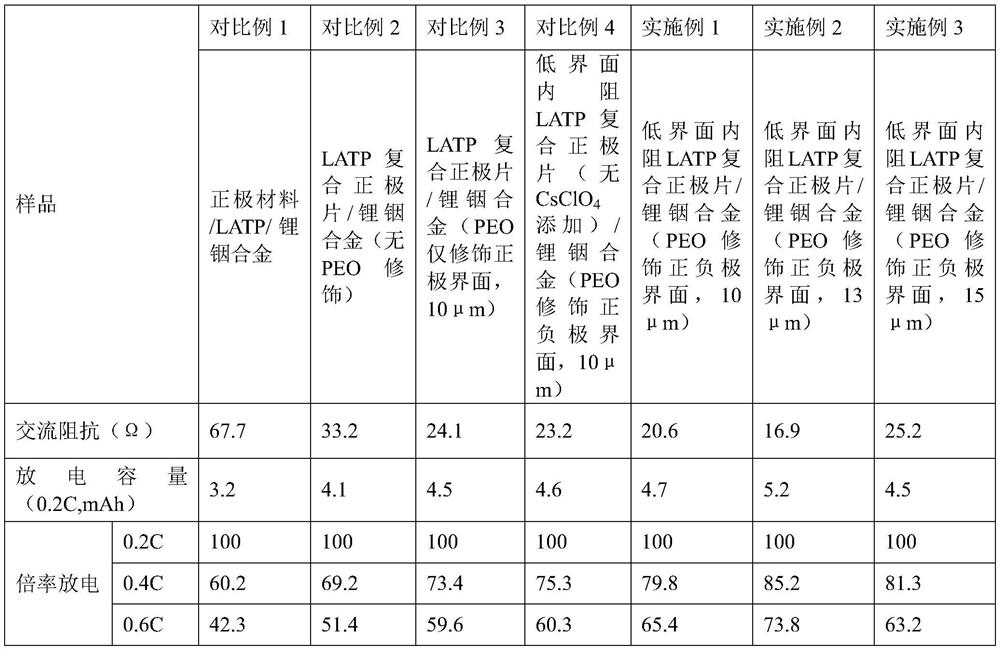

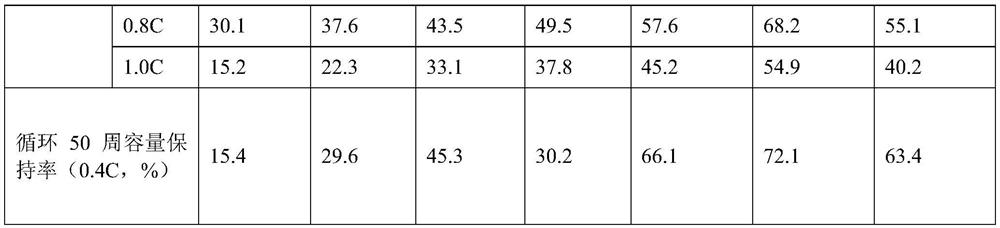

Examples

preparation example Construction

[0039] A method for preparing the LATP composite positive electrode sheet with low interfacial internal resistance is characterized in that, comprising the following steps: a. preparing LATP composite solid electrolyte

[0040] (1) LiNO 3 , Al(NO 3 ) 3 ·9H 2 O and NH 4 H 2 PO 4 Add to the solvent and mix well until completely dissolved;

[0041] (2) adding a citric acid solution with a mass fraction of 10 to 15%, the molar ratio of the citric acid to the metal element in the solution is 1:1 to 1.5, then adding titanium lactate to the mixed solution, at 70 to 80 ° C Stir for 10-20 hours to obtain a viscous liquid;

[0042] (3) calcining the viscous liquid obtained in step (2) at 200-250° C. for 10-30 minutes, and then calcining at 300-350° C. for 2-3 hours to obtain a solid material;

[0043] (4) the solid material, Li obtained in step (3) 4 SiO 4 Mixing with the positive active material in a mass ratio of 25-30:0.5-1.0:25-30, ball milling for 15-20 minutes to obtain ...

Embodiment 1

[0054] A LATP composite positive electrode sheet with low interfacial internal resistance, comprising a positive electrode sheet and a composite solid electrolyte, the positive electrode sheet includes a positive electrode active material and a conductive agent, a positive electrode active material is added to the composite solid electrolyte, and the positive electrode sheet is placed in the On one side of the composite solid electrolyte, the composite solid electrolyte is a PEO-coated LATP composite solid electrolyte.

[0055] The mass ratio of the positive electrode sheet to the composite solid electrolyte is 1.2:2, and in the positive electrode sheet, the mass ratio of the positive electrode active material to the conductive agent is 20:1; the positive electrode active material is lithium iron phosphate; the conductive agent For conductive carbon black.

[0056] A method for preparing the LATP composite positive electrode sheet with low interfacial internal resistance is ch...

Embodiment 2

[0072] A LATP composite positive electrode sheet with low interfacial internal resistance, comprising a positive electrode sheet and a composite solid electrolyte, the positive electrode sheet includes a positive electrode active material and a conductive agent, a positive electrode active material is added to the composite solid electrolyte, and the positive electrode sheet is placed in the On one side of the composite solid electrolyte, the composite solid electrolyte is a PEO-coated LATP composite solid electrolyte.

[0073] The mass ratio of the positive electrode sheet to the composite solid electrolyte is 1:2, and in the positive electrode sheet, the mass ratio of the positive electrode active material to the conductive agent is 15:1; the positive electrode active material is lithium manganate; the conductive agent For conductive graphite.

[0074] A method for preparing the LATP composite positive electrode sheet with low interfacial internal resistance is characterized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com