Preparation method of fibrilia wig

The technology of hemp fiber and hemp fiber is applied in the field of preparation of hemp fiber wigs, which can solve the problems of no antibacterial, itching, and difficulty in dyeing, and achieve the effects of fast ultraviolet absorption, fast moisture absorption and moisture release, and good drapability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of hemp fiber wig, comprising:

[0030] The hemp fiber is subjected to pretreatment, ionic liquid finishing, soft finishing and dyeing finishing to obtain a hemp fiber wig.

[0031] In the present invention, the pretreatment method preferably includes:

[0032] Use a comb to comb the hemp fiber evenly and straightly along the straight line of the fiber to remove the free fibers and short fibers in the fibers, and use tweezers to pick out the hard and filaments and impurities in the fibers.

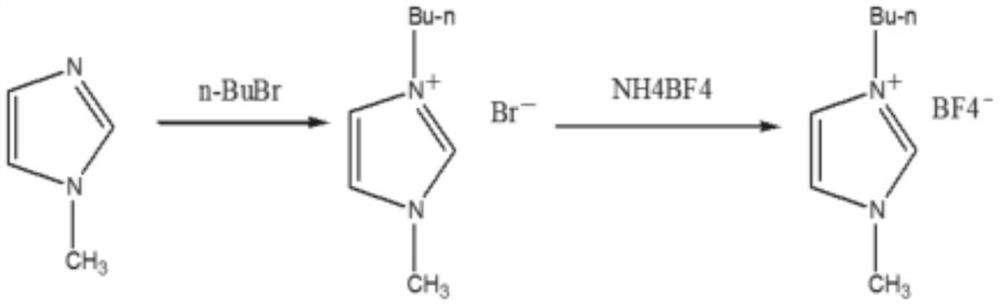

[0033] In the present invention, the method for finishing the ionic liquid preferably includes:

[0034] The pretreated product is treated in an ionic liquid solution.

[0035] In the present invention, the ionic liquid solution preferably includes:

[0036] 1-Methyl-3-n-butyl-imidazolium tetrafluoroborate ionic liquid (BMIBF 4 ) and water.

[0037] The present invention has no special limitation on the source of the 1-methyl-3-n-buty...

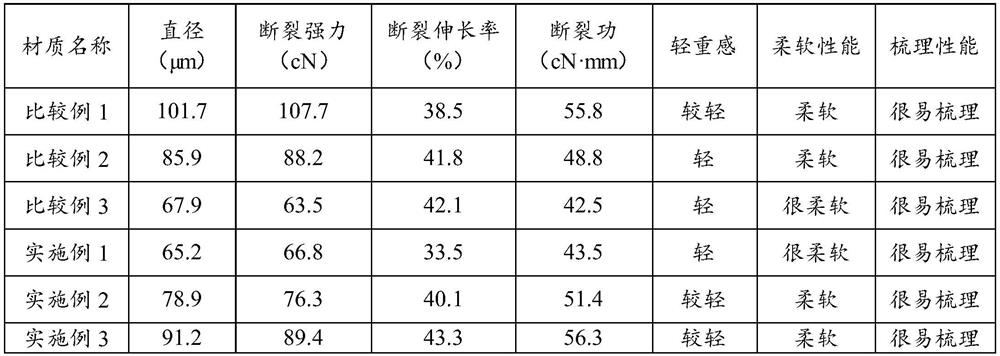

Embodiment 1

[0077] Weigh a hemp fiber sample of about 600g, and use a comb to comb evenly and straightly along the fiber straight line to remove the free fibers and short fibers in the fibers, and use tweezers to remove the hard fibers and impurities in the fibers.

[0078] Use a constant temperature oil bath or water bath to heat the BMIBF 4 After the ionic liquid solution (mass concentration: 5g / L) was heated to 70°C, the carded fibers (the bath ratio of 1:10) were put into it for treatment for about 30min, and ultrasonic vibration was continued during the treatment to ensure uniformity; the treatment was completed. The ionic liquid adhering to the fiber was removed by rolling, rinsed with deionized water, and finally dried in an oven at 80°C or naturally air-dried.

[0079] Put the fibers treated with ionic liquid into the amino silicone oil softener treatment solution (solvent is water) with a mass concentration of 5g / L, the bath ratio is 1:10, the temperature is 40 °C for 10 minutes,...

Embodiment 2

[0082] Weigh about 500g of hemp fiber samples, and use a comb to comb evenly and straightly along the fiber straight line to remove the free fibers and short fibers in the fibers, and use tweezers to pick out the hard fibers and impurities in the fibers.

[0083] Use a constant temperature oil bath or water bath to heat the BMIBF 4 After the ionic liquid solution (mass concentration: 4g / L) is heated to 65°C, the carded fibers (bath ratio of 1:8) are put into it for about 25 minutes, and ultrasonic vibration is continued during the treatment to ensure uniformity; the treatment is completed. The ionic liquid adhering to the fiber was removed by rolling, rinsed with deionized water, and finally dried in an oven at 85°C or air-dried naturally.

[0084] Put the fiber after ionic liquid treatment into the concentration of 3.5g / L, the bath ratio is 1:8, the temperature is 45℃, and the temperature is 45℃ for softening and finishing in the treatment liquid of amino silicon softener (th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com