Nanocrystalline TaNbTi medium-entropy alloy coating and preparation method thereof

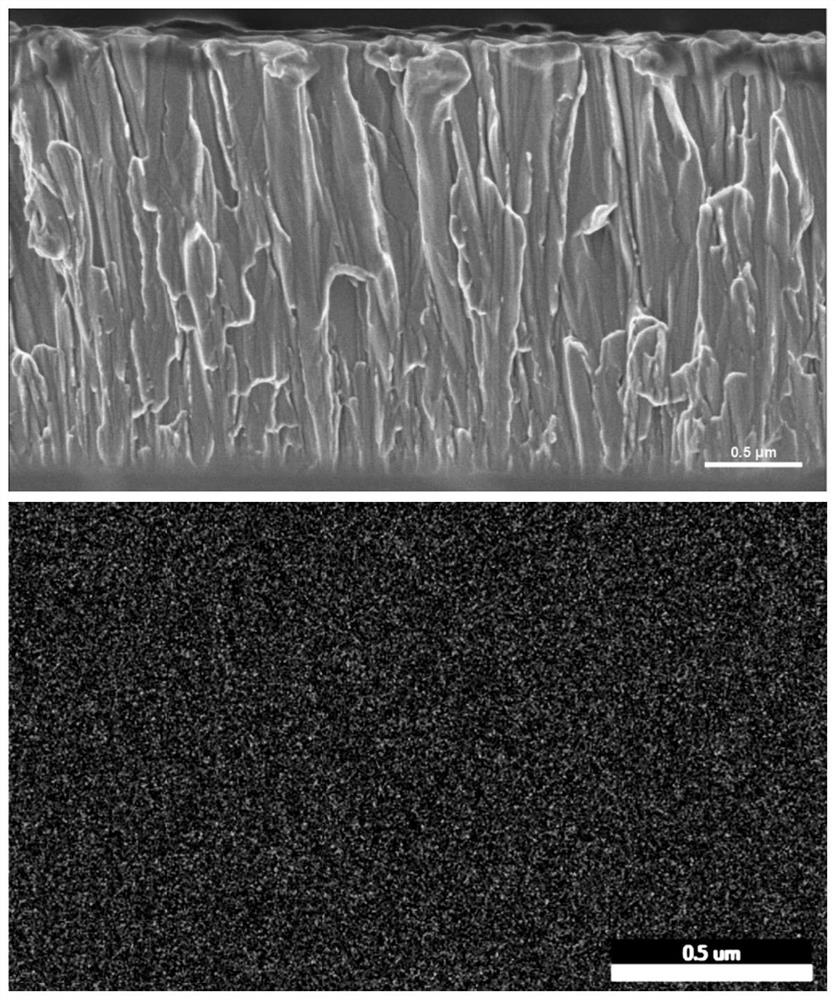

A technology of entropy alloy and high entropy alloy, applied in the field of entropy alloy coating in nanocrystalline TaNbTi and its preparation, can solve the problem that nuclear fuel cannot be completely burned, limit the safe service and service life of fuel cladding tubes, and the service environment of fuel cladding materials. Harsh and other problems, to achieve uniform and dense microstructure, excellent high temperature strength and anti-oxidation performance, good film-based bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of the above-mentioned TaNbTi refractory medium-entropy alloy coating, comprising the following steps:

[0030] Step 1: ultrasonically clean and dry the surface of the substrate;

[0031] Take the single-crystal silicon substrate polished on one side, ultrasonically clean it in acetone and ethanol for 10 minutes in turn, and dry it to ensure that the surface of the substrate is clean and free of stains and dust. The surface roughness of the single-crystal silicon substrate after ultrasonic cleaning is less than 0.8nm. Ultrasonic cleaning of the polished single crystal silicon substrate is beneficial to improve the bonding force between the coating and the substrate and improve the quality of film formation.

[0032] The substrates are single crystal silicon substrates and steel substrates.

[0033] Step 2: Vacuum etching the substrate.

[0034] The single crystal silicon substrate after ultrasonic cleaning is fi...

Embodiment 1

[0040] Step 1: The single-crystal silicon substrate polished on one side was ultrasonically cleaned in acetone and ethanol for 10 minutes, respectively, and dried with a hair dryer.

[0041] Step 2: Fix the substrate on the substrate, and then automatically accompany it into the vacuum coating chamber. The vacuum degree of the backside should be lower than 4.0×10 before deposition. -4Pa, and etching for 5min, the etching power is 200W.

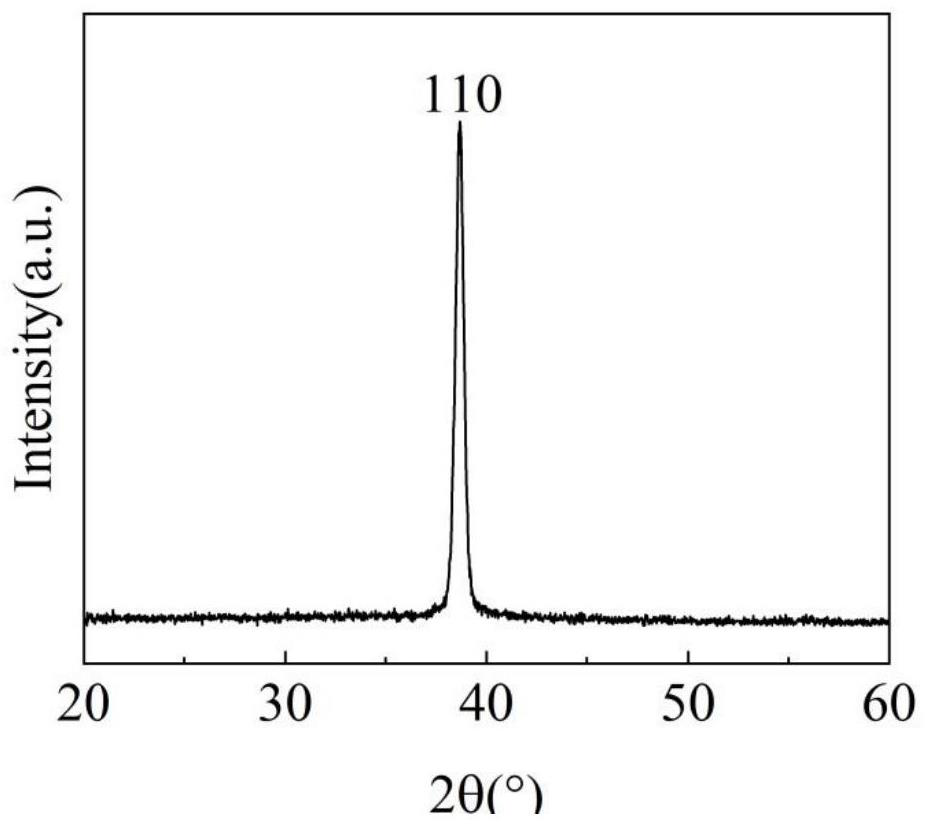

[0042] Step 3: A TaNbTi refractory medium-entropy alloy coating was prepared by DC magnetron sputtering of two TaNbTi alloy targets.

[0043] Among them, the purity of TaNbTi alloy target is 99.9wt.% (Ta:Nb:Ti=30.8:32.5:36.7at.%) using DC power supply, the power of both targets is 100W, the deposition time is 18000s, and the working pressure is set to 0.3Pa , the deposition temperature was room temperature, and the substrate speed was 15 r / min.

[0044] Step 4: After the deposition, the substrate is naturally cooled in a vacuum coating chamb...

Embodiment 2

[0047] Step 1: The steel substrate was ultrasonically cleaned in acetone and ethanol for 10 min, and dried with a hair dryer.

[0048] Step 2: Fix the substrate on the substrate, and then automatically accompany it into the vacuum coating chamber. The vacuum degree of the background should be lower than 4.0×10 before deposition. -4 Pa, and etching for 5min, the etching power is 200W.

[0049] Step 3: A TaNbTi refractory medium-entropy alloy coating was prepared by DC magnetron sputtering of two NbMoTaW alloy targets.

[0050] Among them, the purity of NbMoTaW alloy target is 99.9wt.% (Ta:Nb:Ti=30.8:32.5:36.7at.%) using DC power supply, the power of both targets is 150W, the deposition time is 25000s, and the working pressure is set to 0.3Pa , the deposition temperature was room temperature, and the substrate speed was 15 r / min.

[0051] Step 4: After the deposition, the substrate is naturally cooled in a vacuum coating chamber for 5 hours and taken out to obtain a TaNbTi ref...

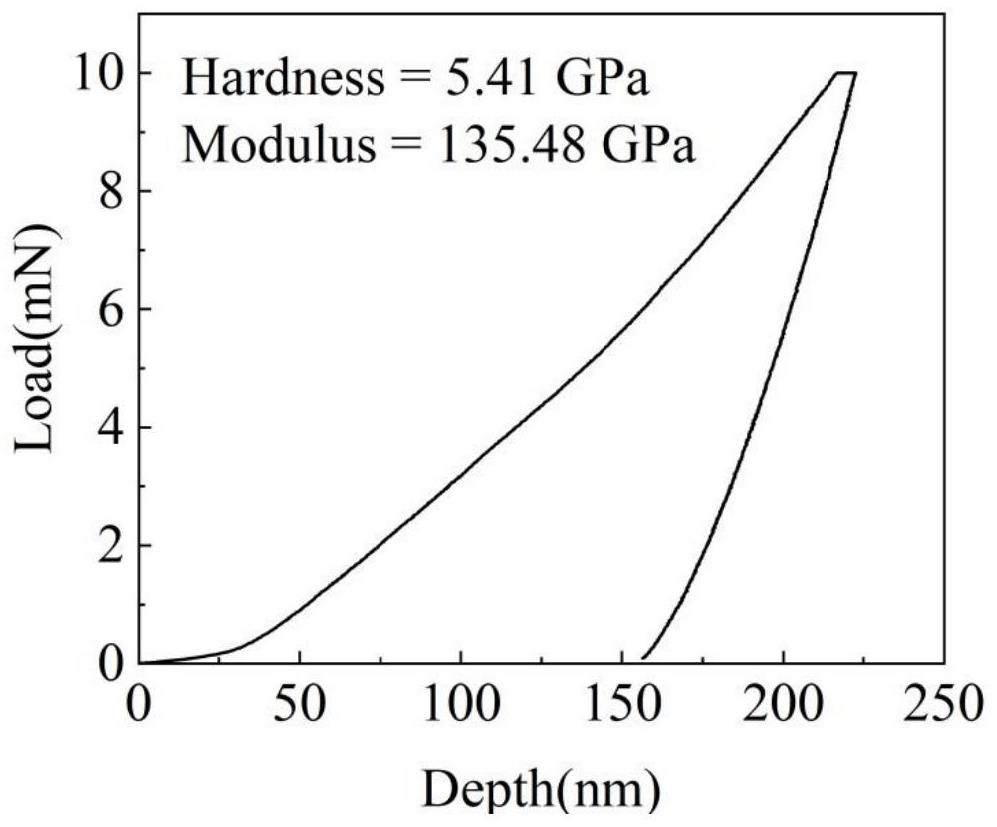

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com