Self-assembled fresh ginger essential oil microcapsule and preparation method thereof

A technology of ginger essential oil and self-assembly, applied in directions such as microcapsules, capsule delivery, and drug combination, can solve problems such as poor stability of ginger essential oil, and achieve the effects of good biological safety, high production efficiency, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

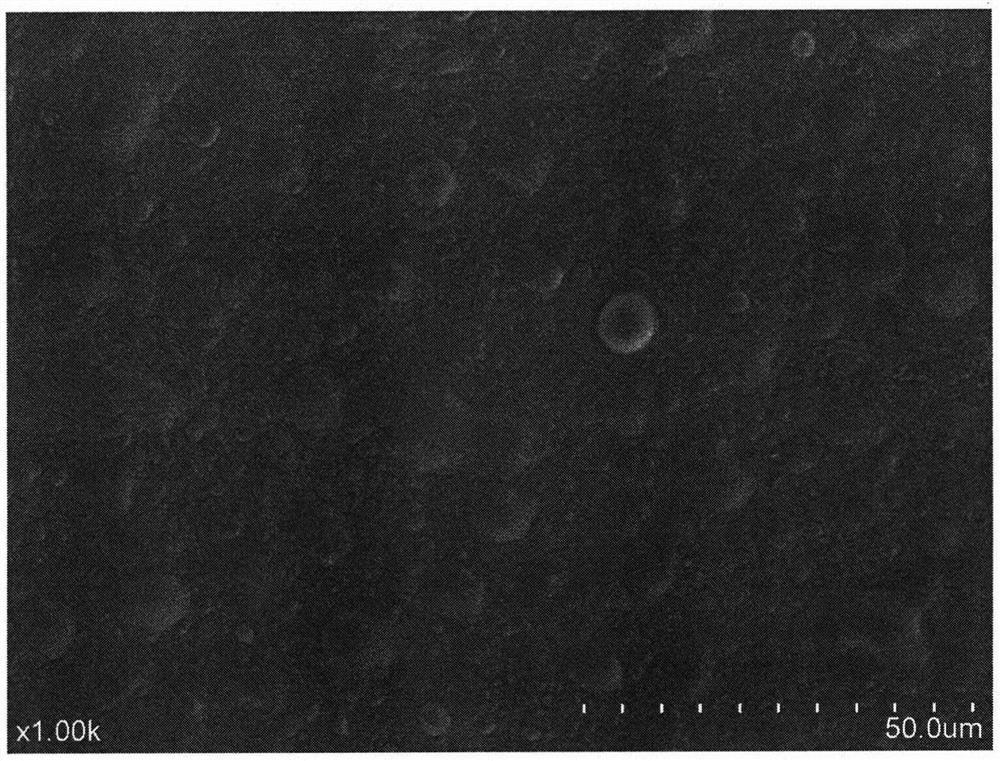

Image

Examples

Embodiment 1

[0029] Take 2% lecithin, dissolve the two wall materials in acetate buffer with a ratio of 1:3 of chitosan:lecithin, stir with a magnetic stirrer at a speed of 700r / min for 20min, Lecithin and chitosan stock solutions were obtained, respectively. Mix 5% ginger essential oil, 2.5% ethanol and 2% Tween 80, add it to the lecithin stock solution, and stir it with a constant temperature magnetic stirrer at a speed of 800 r / min for 25 minutes to obtain a primary emulsion; The sugar stock solution was added to the primary emulsion, and stirred at a constant temperature of 40 °C and a speed of 800 r / min for 30 min to obtain a secondary emulsion; after adjusting the pH of the secondary emulsion to 3, homogenize at 17000 r / min for 20 min Wet microcapsules are obtained; after the wet microcapsules are pre-frozen at -80° C. for 24 hours, and then vacuum freeze-dried for 48 hours, the self-assembled ginger essential oil microcapsules are obtained.

Embodiment 2

[0031] Take 1% pectin, dissolve the two wall materials in acetate buffer at a ratio of pectin: soybean protein isolate of 1:5, stir with a magnetic stirrer at a speed of 800 r / min for 13 min, Pectin and soy protein isolate stock solutions were obtained, respectively. Mix 3% ginger essential oil, 1% glycerol and 1.5% fatty acid monoglyceride, add it to the pectin stock solution, and stir it with a constant temperature magnetic stirrer at a speed of 900r / min for 30min to obtain a primary emulsion; The protein isolate stock solution was added to the primary emulsion, and stirred at a constant temperature of 50 °C and a speed of 700 r / min for 40 min to obtain a secondary emulsion; after adjusting the pH value of the secondary emulsion to 4.5, homogenize at 18000 r / min. Wet microcapsules were obtained in 15 minutes; the wet microcapsules were pre-frozen at -80°C for 24 hours, and then vacuum freeze-dried for 48 hours to obtain self-assembled ginger essential oil microcapsules.

Embodiment 3

[0033] Get 0.4% calcium stearoyl lactylate, dissolve two kinds of wall materials in the phosphate buffer solution with calcium stearoyl lactylate: gelatin at a ratio of 1:9 respectively, and use a magnetic stirrer under the speed condition of 950r / min. Stir for 25 min to obtain calcium stearoyl lactylate and gelatin stock solutions, respectively. Mix 9% ginger essential oil, 4.5% propylene glycol and 3% Tween 20 with span40 compound emulsifier, add it to the calcium stearoyl lactylate stock solution, and stir with a constant temperature magnetic stirrer at a speed of 10000r / min 18min to obtain the primary emulsion; add the gelatin stock solution to the primary emulsion, stir at a constant temperature of 45°C and a speed of 900r / min for 26min to obtain the secondary emulsion; after adjusting the pH of the secondary emulsion to 6, at 20000r / min The wet microcapsules were obtained by homogenizing for 10 minutes under the condition of -1 The self-assembled ginger essential oil mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com