Calamine hemostatic compound based on Y molecular sieve carrier and preparation thereof

A molecular sieve and calamine technology, applied in the field of biomedical materials, can solve the problems of inflammation and local vasodilation, unfavorable wound hemostasis healing, bacterial infection, etc., and achieve high hemostatic performance, good biosafety, prothrombin time improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

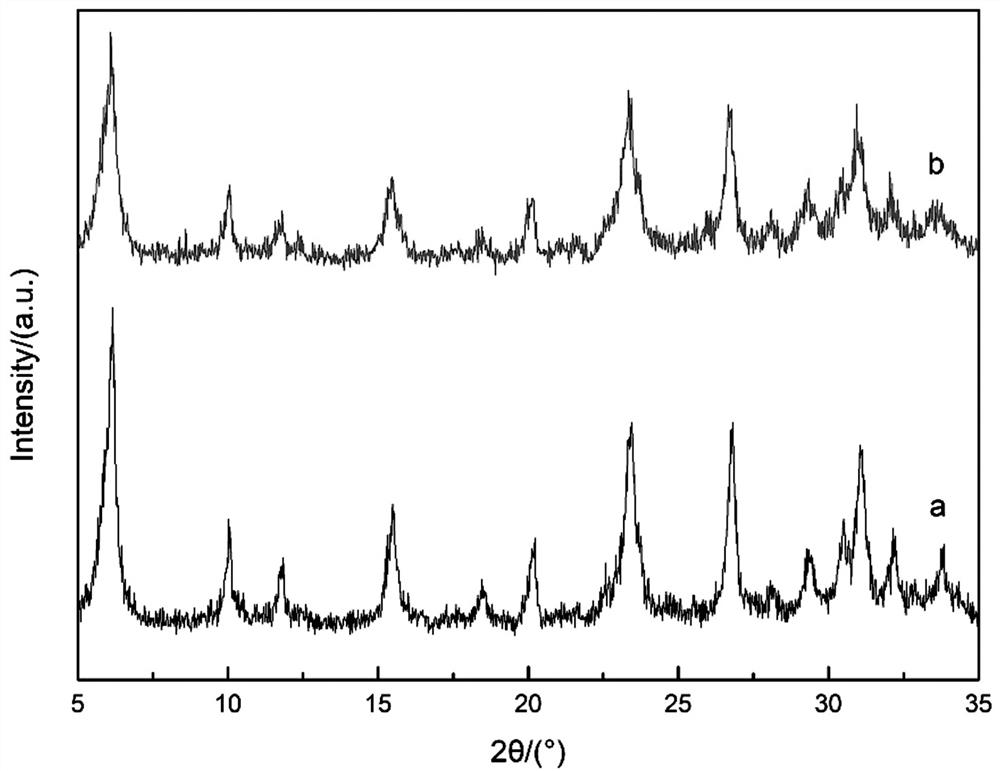

[0039] Add 30mL of deionized water, 2.33g of sodium hydroxide, 0.2g of sodium chloride, 1.99g of sodium metaaluminate, and 4.33mL of 40% silica sol into a container lined with polytetrafluoroethylene, and stir for 60 minutes at room temperature.

[0040] Afterwards, the container was placed in a water bath at 25°C, stirred at a constant temperature for 24 hours, then the temperature of the water bath was raised to 45°C, stirred at a constant temperature for 24 hours, and finally the temperature was raised to 60°C and stirred at a constant temperature for 12 hours, then the stirring was stopped.

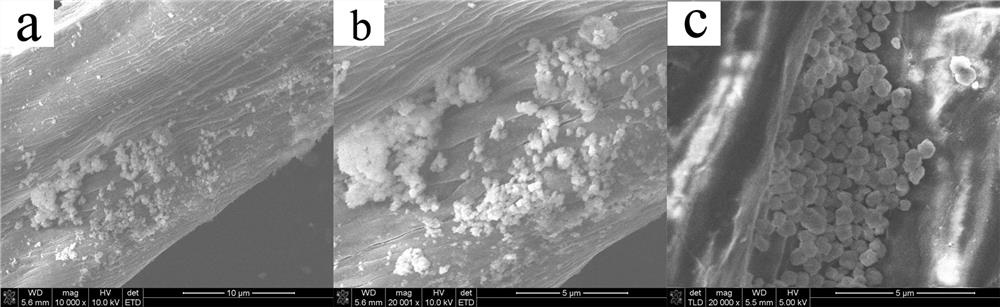

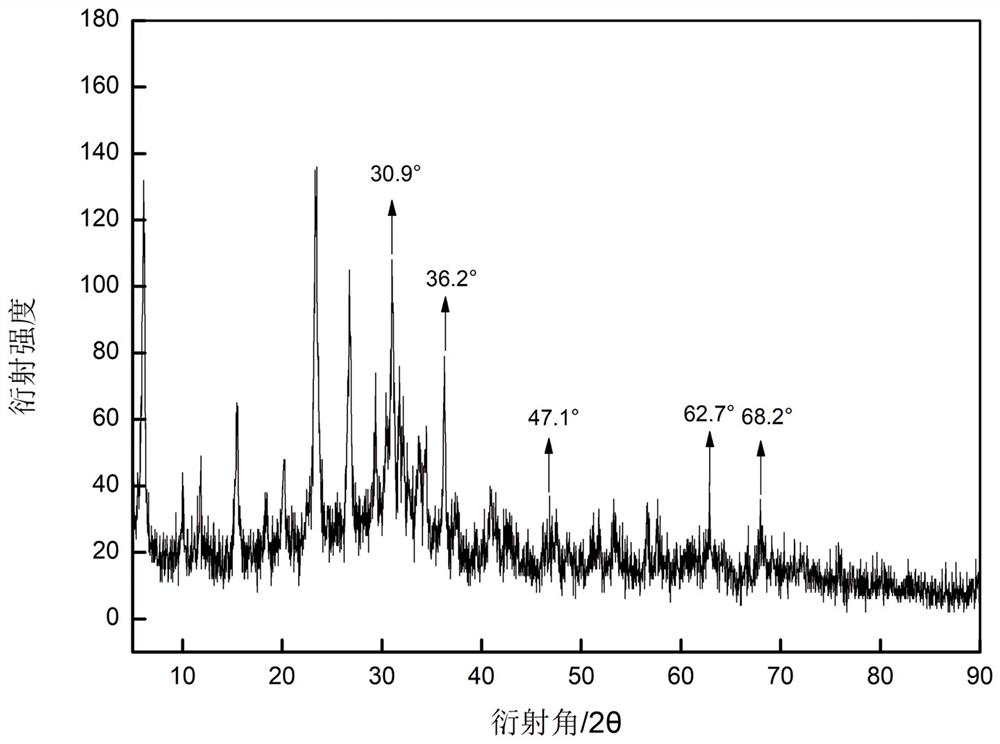

[0041] Add a layer of medical absorbent cotton and sprinkle a layer of calamine, add 1.5g of medical absorbent cotton torn into fiber sheets and 0.2g of calamine into a container with a polytetrafluoroethylene liner, put it into a stainless steel reaction The kettle was sealed, and heated to 100°C in a constant temperature box for 24 hours of constant temperature crystallization reacti...

Embodiment 2

[0057] Add 35mL of deionized water, 1.285g of sodium hydroxide, 0.2g of sodium chloride, 1.99g of sodium metaaluminate, and 2.33g of white carbon black in sequence in a container lined with polytetrafluoroethylene, and stir for 60 minutes at room temperature.

[0058] Afterwards, the container was placed in a water bath at 25°C, stirred at a constant temperature for 24 hours, then the temperature of the water bath was raised to 45°C, stirred at a constant temperature for 24 hours, and finally the temperature was raised to 60°C and stirred at a constant temperature for 12 hours, then the stirring was stopped.

[0059] Add a layer of medical absorbent cotton and sprinkle a layer of calamine, add 1.5g of medical absorbent cotton torn into fiber sheets and 0.27g of calamine into a container with a polytetrafluoroethylene liner, put it into a stainless steel reaction The kettle was sealed, and heated to 100°C in a constant temperature box for 24 hours of constant temperature crystal...

Embodiment 3

[0062] Add 32mL of deionized water, 1.8g of sodium hydroxide, 0.2g of sodium chloride, 3.41g of sodium metaaluminate, and 9.7mL of 40% silica sol into a container lined with polytetrafluoroethylene, and stir for 60 minutes at room temperature.

[0063] Afterwards, the container was placed in a water bath at 25°C, stirred at a constant temperature for 24 hours, then the temperature of the water bath was raised to 45°C, stirred at a constant temperature for 24 hours, and finally the temperature was raised to 60°C and stirred at a constant temperature for 12 hours, then the stirring was stopped.

[0064] Add a layer of medical absorbent cotton and sprinkle a layer of calamine, add 1.0g of medical absorbent cotton torn into fiber sheets and 0.15g of calamine into a container with a polytetrafluoroethylene liner, put it into a stainless steel reaction The kettle was sealed, and heated to 100°C in a constant temperature box for 24 hours of constant temperature crystallization reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com