Nano ceramic coating and use method thereof

A nano-ceramic and coating technology, applied in coatings and other directions, can solve the problems of high price of commercial coatings, difficult to balance the hydrophobicity and adhesion of hydrophobic coatings, and achieve good adhesion and flatness, excellent anti-ultraviolet ability, Durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

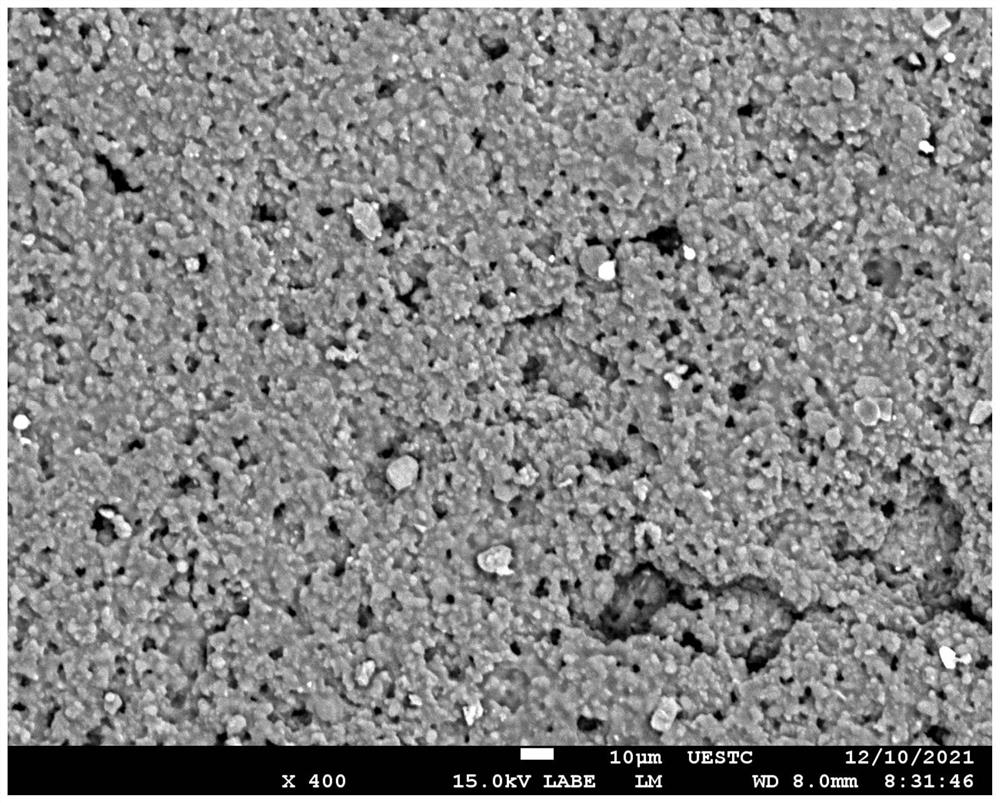

[0027] 0.4 g of nano-silica powder, 0.4 g of nano-titanium dioxide powder, 0.9 g of polydimethylsiloxane, 0.835 g of fluorocarbon resin, and 12 g of ethyl acetate were mixed to obtain coating component A.

[0028] 0.1 g of ethyl orthosilicate, 0.2 g of dibutyltin dilaurate, and 0.165 g of isocyanate were mixed to obtain a topcoat coating component B.

[0029] All components A and B of the hydrophobic nano-ceramic coating were added to a beaker and mixed, and the beaker containing the mixed hydrophobic nano-ceramic coating was placed in an ultrasonic cleaner for ultrasonic treatment for 3 minutes.

[0030] The hydrophobic nano-ceramic coating completed by ultrasonic dispersion is loaded into the spray gun and sprayed evenly on the surface of the substrate.

[0031] The sprayed aluminum plate was put into an oven, the oven temperature was set to 50° C., and the temperature was maintained for 2 hours, and then a hydrophobic nano-ceramic coating was obtained.

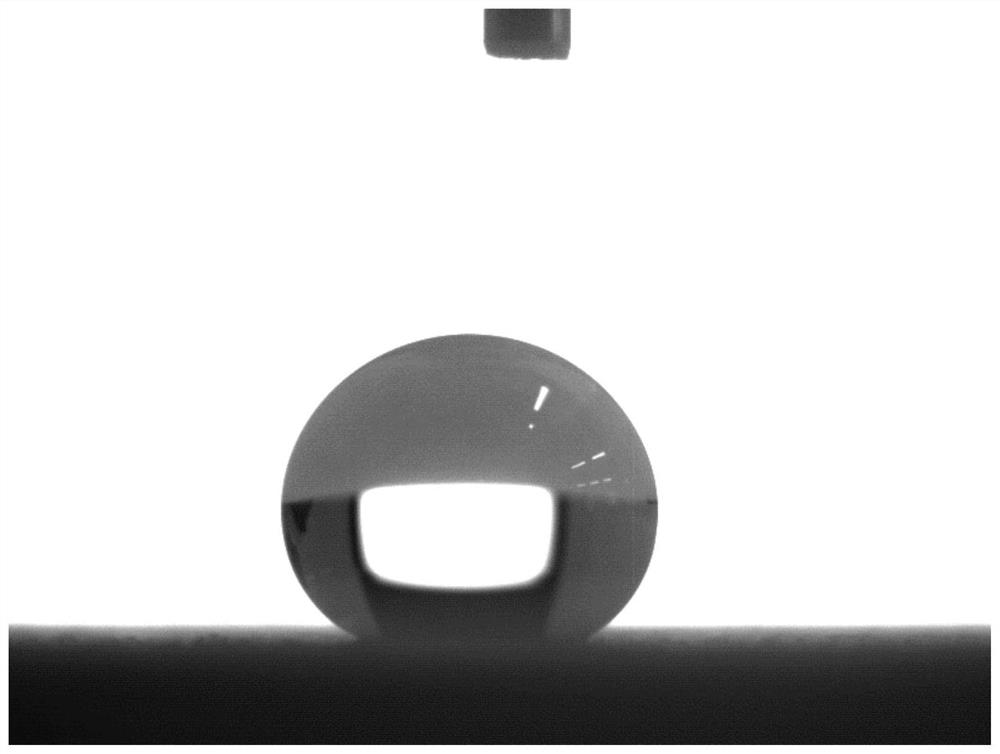

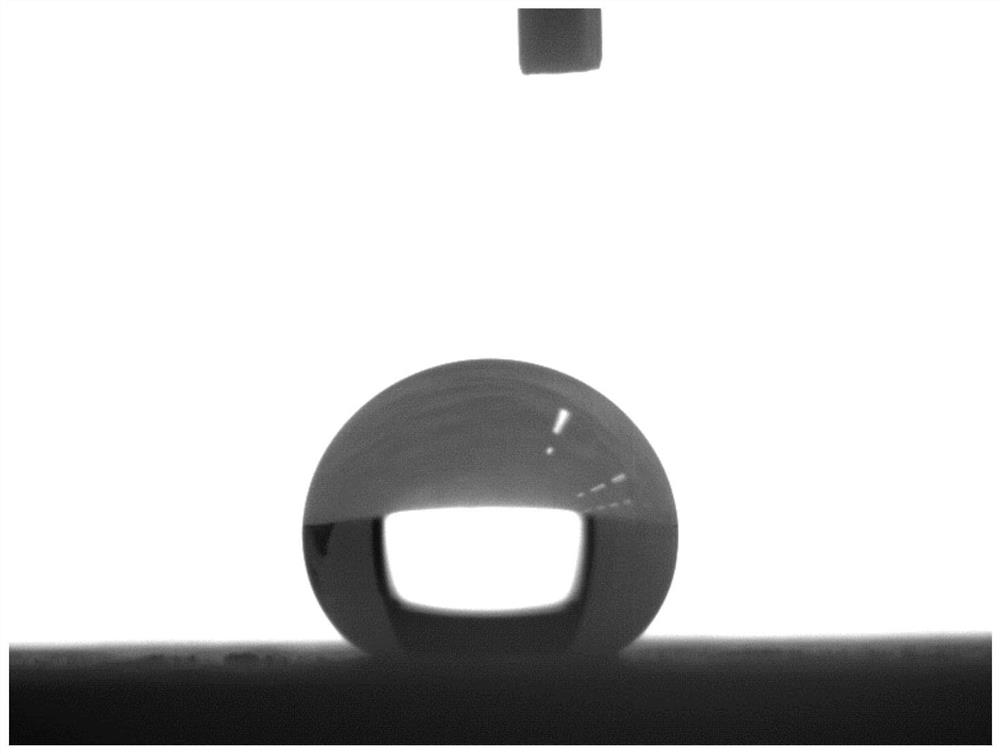

[0032] The test an...

Embodiment 2

[0034] Coating component A was obtained by mixing 0.3 g of nano-silica powder, 0.3 g of nano-titanium dioxide powder, 0.9 g of polydimethylsiloxane, 0.835 g of fluorocarbon resin, and 12 g of ethyl acetate.

[0035] 0.1 g of ethyl orthosilicate, 0.2 g of dibutyltin dilaurate, and 0.165 g of isocyanate were mixed to obtain a topcoat coating component B.

[0036] The coating preparation method is the same as that of Example 1.

[0037] The test analysis of the hydrophobic nano-ceramic coating is as follows, the contact angle of the coating is 141.93°, the contact angle after irradiation is 140.35°, the contact angle after sanding is 130.22°, the rolling angle of the coating is 16.61°, and the surface roughness is 3.2 μm. Icing gain 0.2g.

Embodiment 3

[0039] Coating component A was obtained by mixing 0.4 g of nano-silica powder, 0.2 g of nano-titanium dioxide powder, 0.9 g of polydimethylsiloxane, 0.835 g of fluorocarbon resin, and 12 g of ethyl acetate.

[0040] 0.1 g of ethyl orthosilicate, 0.2 g of dibutyltin dilaurate, and 0.165 g of isocyanate were mixed to obtain a topcoat coating component B.

[0041] The coating preparation method is the same as that of Example 1.

[0042] The test analysis of the hydrophobic nano-ceramic coating is as follows, the contact angle of the coating is 136.72°, the contact angle after irradiation is 136.14°, the contact angle after sanding is 122.41°, the rolling angle of the coating is 17.06°, and the surface roughness is 3.2 μm. Icing gain 0.2g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Antenna | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com