Transparent polystyrene with ultraviolet aging resistance and good yellowing resistance and preparation method thereof

A transparent polystyrene, UV-resistant technology, applied in the field of polystyrene resin, can solve the problem of high cost, achieve the effect of prolonging the service life, eliminating yellowing, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

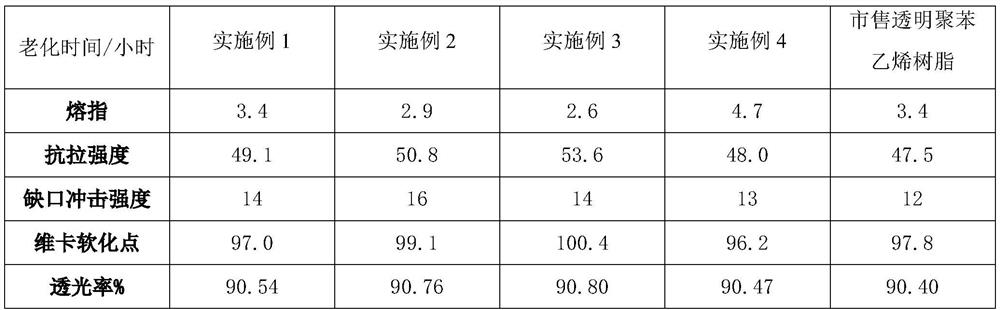

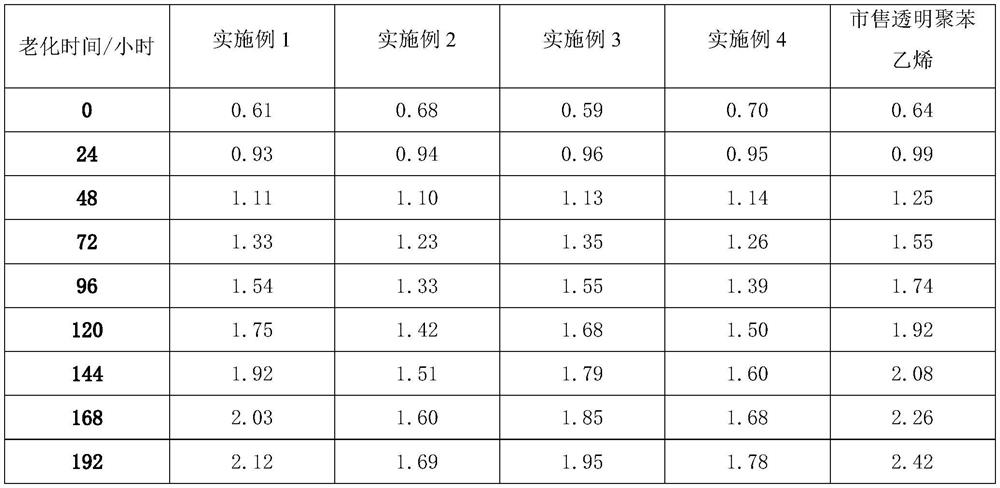

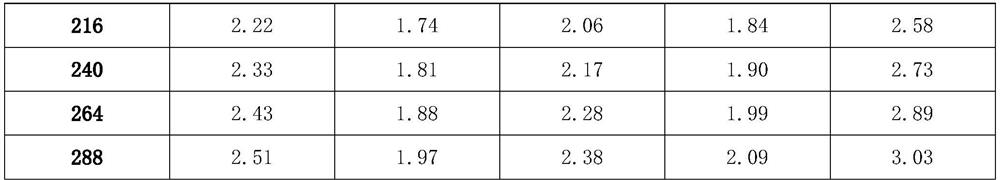

Examples

Embodiment 1

[0037] A transparent polystyrene with UV aging resistance and good yellowing resistance, consisting of the following components in parts by weight: 115 parts of styrene, 2.55 parts of white oil, 1 part of zinc stearate, 0.5 parts of calcium stearate lubricant 0.001 part of Iganox168, 0.001 part of Tinuvin327, 0.15 part of tert-butyl peroxybenzoate, 0.2 part of tert-butyl peroxypivalate, 2 parts of ethylbenzene, 2 parts of sulfide, poly a-ph methyl 1 part of styrene.

[0038] The preparation method of above-mentioned embodiment 1, comprises the steps:

[0039] 1. Preparation of materials:

[0040] Weigh materials such as styrene, lubricant, antioxidant, light stabilizer, initiator and chain transfer agent in proportion, store them in predetermined storage tanks, and use corresponding conveying equipment to transport the materials according to the predetermined flow rate to the preheating and prepolymerizing device;

[0041] 2. Prepolymerization reaction:

[0042] Continuous...

Embodiment 2

[0054] A transparent polystyrene with UV aging resistance and good yellowing resistance, consisting of the following components in parts by weight: 115 parts of styrene, 0.01 part of paraffin, 0.25 part of magnesium stearate, 0.25 part of acyl stearate, BHT 0.1 part, Irganox10760.2 part, Tinuvin UVP 0.1 part, Tinuvin320 0.2 part, 1,1 di-tert-butylperoxy-3 0.1 part, 3,5 trimethylcyclohexane 0.3 part, 1,1 di-tert-butyl 0.1 part of base peroxy-cyclohexane, 1 part of thioether, 1 part of poly-a-ph methylstyrene, and 2 parts of terpinolene.

[0055] The preparation method of above-mentioned embodiment 2, comprises the steps:

[0056] 1. Preparation of materials:

[0057] Weigh materials such as styrene, lubricant, antioxidant, light stabilizer, initiator and chain transfer agent in proportion, store them in predetermined storage tanks, and use corresponding conveying equipment to transport the materials according to the predetermined flow rate to the preheating and prepolymerizin...

Embodiment 3

[0071] A transparent polystyrene with UV aging resistance and good yellowing resistance, consisting of the following components in parts by weight: 110 parts of styrene, 0.01 part of white oil, 0.01 part of zinc stearate, 0.2 part of Irganox1076, and 0.35 part of Irganox1010 , 0.0001 part of Tinuvin327, 0.25 part of 1,1-di-tert-butylperoxy-cyclohexane, 0.3 part of tert-butylperoxynonanoate, and 0.001 part of ethylbenzene.

[0072] The preparation method of above-mentioned embodiment 3, comprises the steps:

[0073] 1. Preparation of materials:

[0074] Weigh materials such as styrene, lubricant, antioxidant, light stabilizer, initiator and chain transfer agent in proportion, store them in predetermined storage tanks, and use corresponding conveying equipment to transport the materials according to the predetermined flow rate to the preheating and prepolymerizing device;

[0075] 2. Prepolymerization reaction:

[0076] Continuously and stably transport the material in step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com