Preparation method of high-thermal-conductivity insulating heat-conducting layer

An insulating and thermally conductive layer, high thermal conductivity technology, applied in the direction of printed circuit manufacturing, manufacturing printed circuit precursors, printed circuit components, etc., can solve the problems of decreased PCB toughness, poor thermal conductivity, limited thermal conductivity, etc. Strength, simple machinability, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

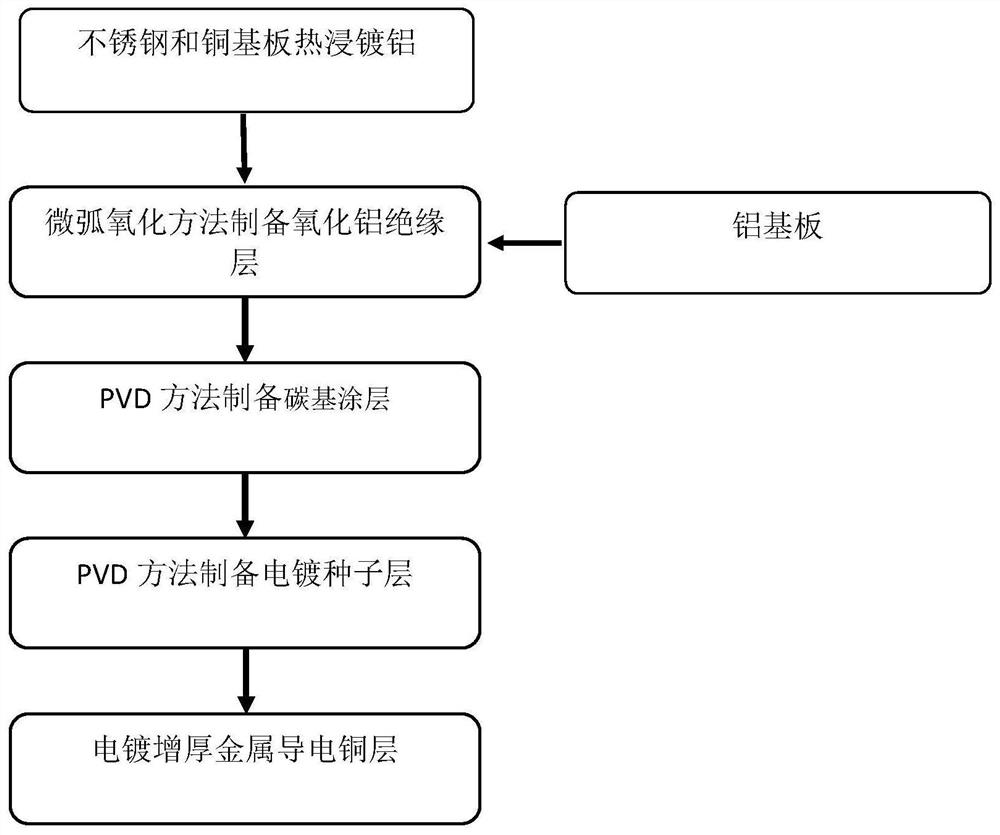

[0031] like figure 1 As shown, the preparation method of a high thermal conductivity insulating heat conduction layer provided by the present invention adopts micro-arc oxidation technology to prepare the insulating layer on the surface of the aluminum substrate, and improves the withstand voltage value of the aluminum oxide insulating layer through the atomic level filling technology of carbon ions, and at the same time Improve the thermal conductivity of the insulating layer, and solve the heat dissipation and heat resistance problems of power electronic devices caused by the substantial increase in power density and calorific value. Specifically include the following steps:

[0032] Step 1. Preparation of alumina insulating layer

[0033] Select a pure aluminum substrate of grade 1050 with a thickness of 1-1.5mm, and prepare an aluminum oxide insulating layer with a thickness of 50±10μm on the surface of the aluminum substrate by micro-arc oxidation, and the thickness of t...

Embodiment 2

[0048] Prepare a layer of aluminum film by hot-dipping aluminum on the surface of the stainless steel substrate, and then complete the preparation of the insulating heat-conducting layer and the surface metal layer according to Example 1, including the following steps:

[0049] Step 1, hot-dip plating on the surface of the stainless steel substrate to prepare an aluminum layer

[0050] The surface of the stainless steel substrate is degreased and then dried, and industrial pure aluminum is used as the raw material for hot-dip plating at a temperature of 750°C. The thickness of the aluminum layer is 80-100 μm after hot-dip plating.

[0051] Step 2. Preparation of alumina insulating layer

[0052] After the aluminum film is prepared on the stainless steel substrate, the surface micro-arc oxidation method is used to prepare the aluminum oxide insulating layer with a thickness of 50 ± 10 μm, and the thickness of the dense layer is ≥ 30 μm. Specific preparation process:

[0053] Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com