Cylinder for an internal combustion engine for a manually guided implement

一种内燃机气缸、手工操作的技术,应用在机器/发动机、汽缸、汽缸盖等方向,能够解决影响压合连接等问题,达到几何构形简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

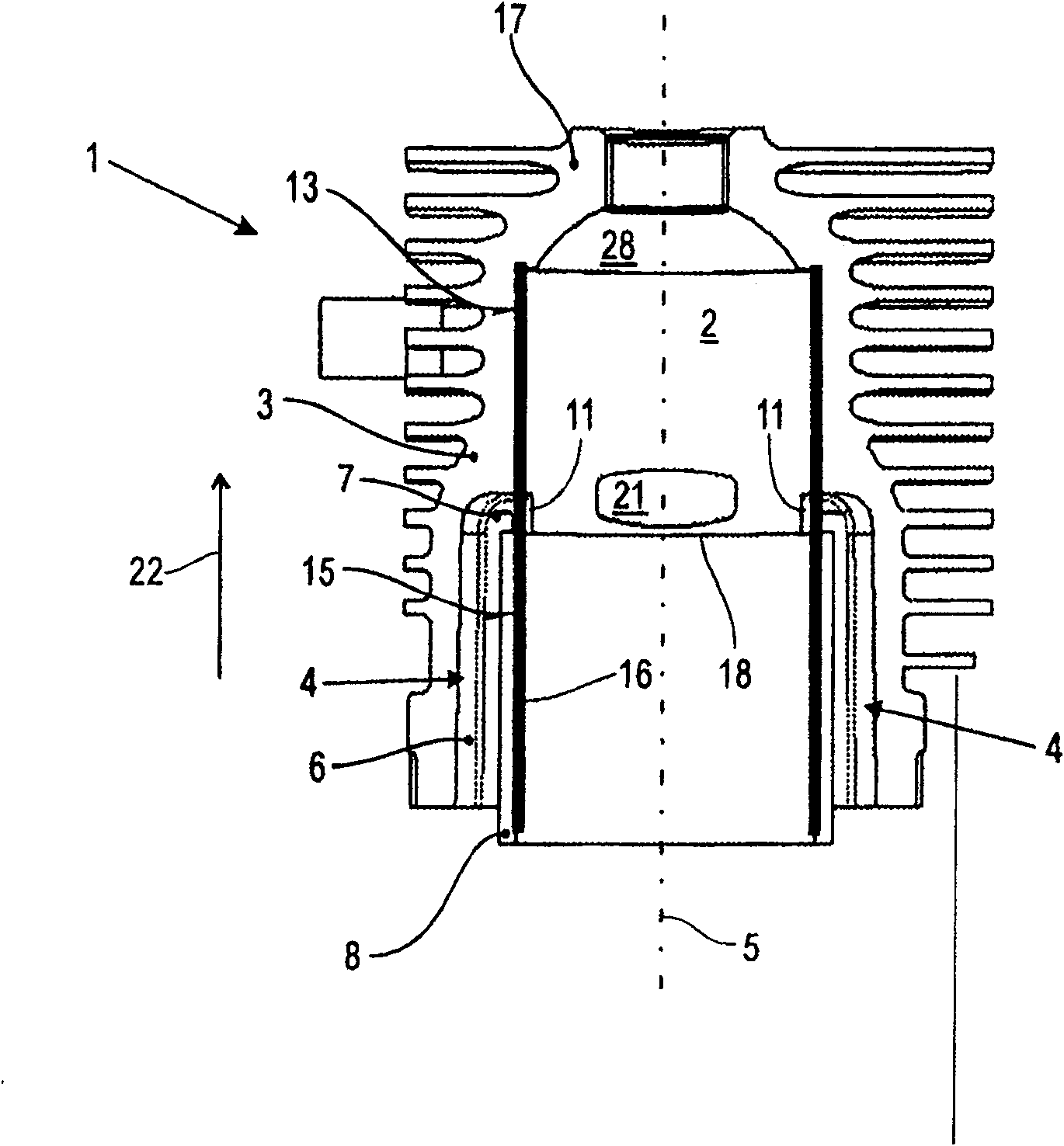

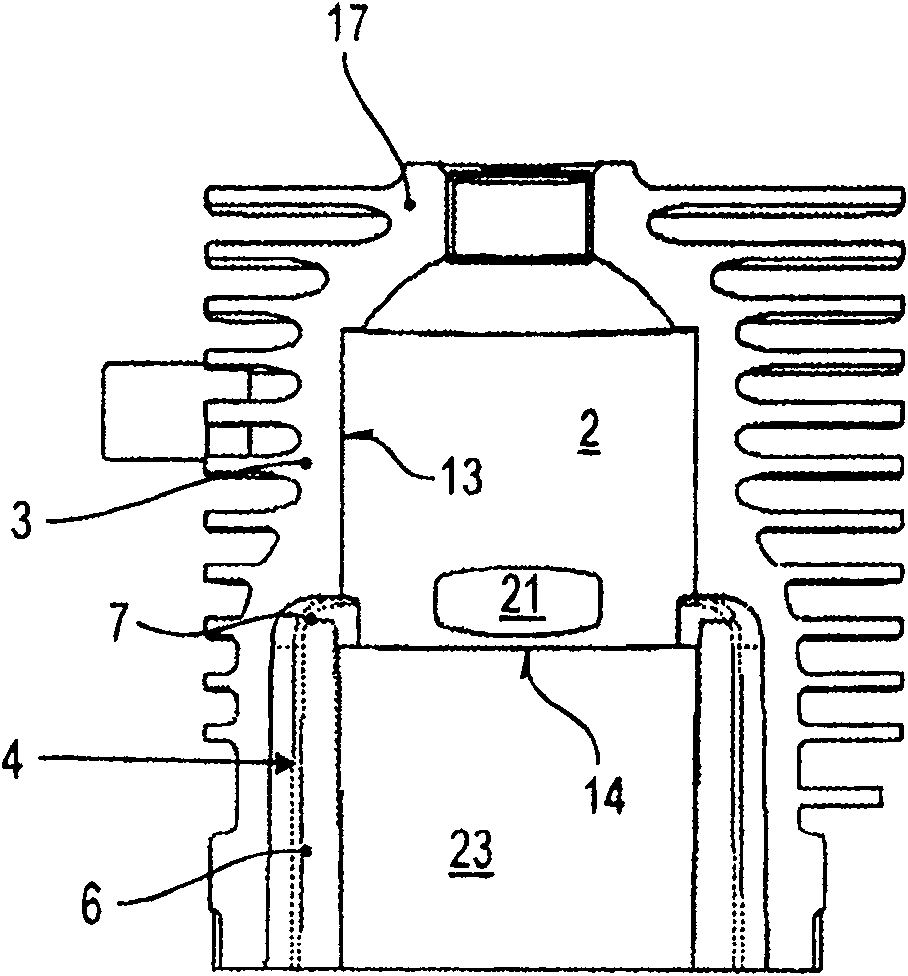

[0027] figure 1 A cylinder 1 of an internal combustion engine for a manual machine is shown in longitudinal section. The cylinder 1 comprises a cast cylinder block 3 and a also cast cylinder head 17 . A cylinder chamber 2 is formed around the periphery by the cylinder block 3 . The cylinder chamber 2 contains an approximately spherically convex fuel chamber 28 which defines the height direction 22 of the cylinder 1 . The cylinder head 17 is connected to the cylinder block 3 along the height direction 22, and is designed to be integral with the cylinder block. The cylinder head 17 can also be connected to the cylinder block 3 using threads under the middle layer of the cylinder head sealing body.

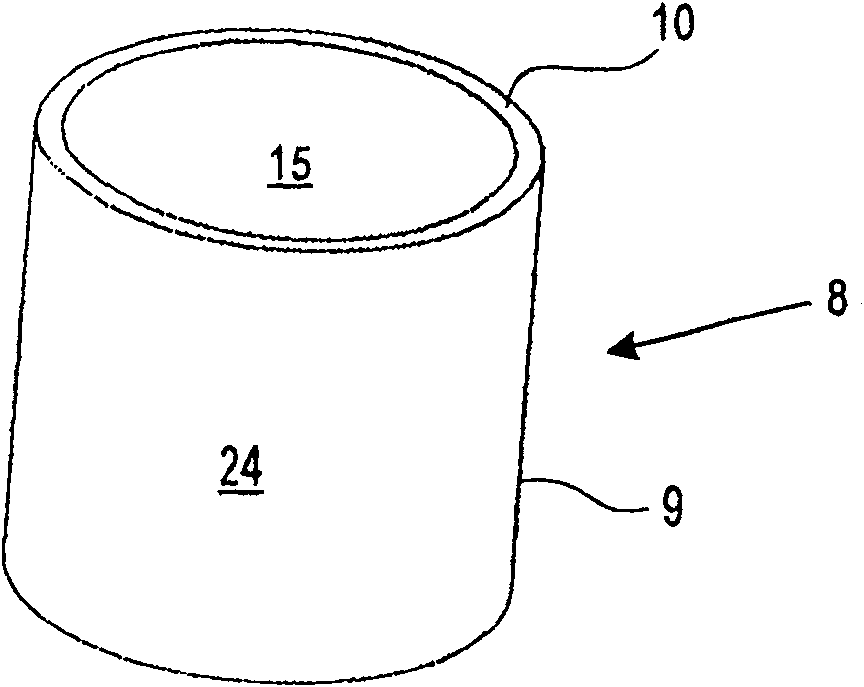

[0028] In the exemplary embodiment shown, the cylinder 1 has two overflow tubes 4 which are approximately diametrically opposite with respect to the cylinder axis 5 and which each comprise a central part 6 extending approximately parallel to the cylinder axis 5 and A section 7 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com