Easily cut and easily hot-forged brass alloy suitable for horizontal continuous casting

A brass alloy and horizontal continuous casting technology, which is applied in the field of brass alloy materials, can solve the problems of unsatisfactory hot forging and rolling effects, poor surface quality of horizontal continuous castings, and low cutting performance, so as to increase the machining performance , easy cutting, good hot forging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

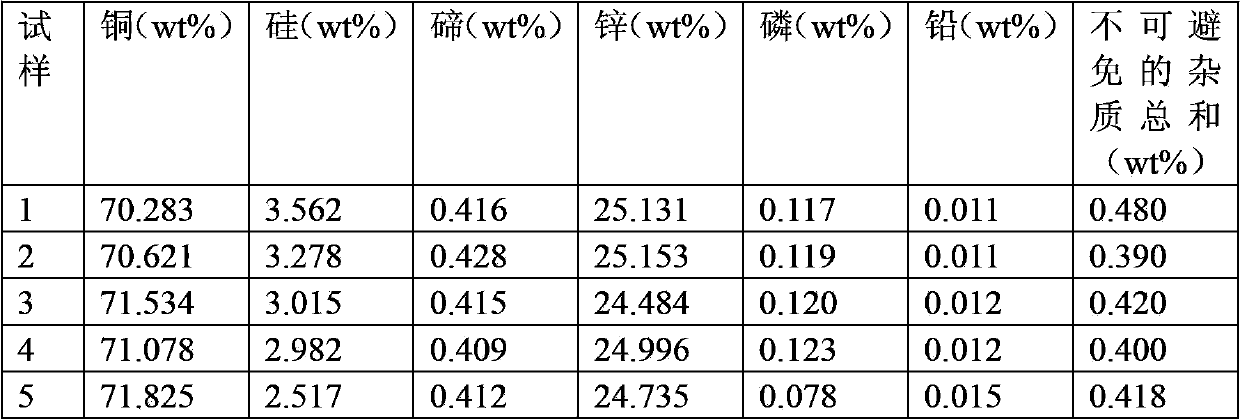

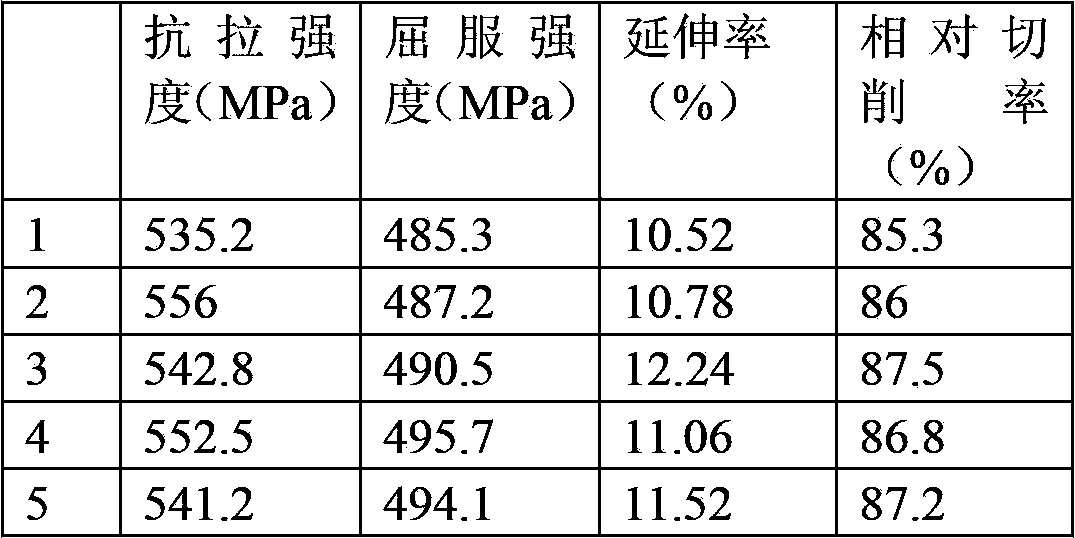

[0011] Adopt the method of horizontal continuous casting, cover with calcined charcoal and cryolite for smelting, according to the required composition content of copper, silicon, tellurium, zinc, phosphorus and the purity of different raw materials, calculate the weight of each raw material required, first add Copper, after heating to 1050-1100°C and melting the copper, raise the temperature to 1150°C and add silicon and tellurium, then cool down to 1000°C and add zinc and phosphorus piece by piece. After that, raise the pouring temperature to 1100-1150°C, keep it warm for 40 minutes, pull out the copper rod with a horizontal tractor, and the dummy speed is 420mm / min, and obtain the brass alloy suitable for horizontal continuous casting, easy cutting and easy hot forging, according to YS / T482-2005 Copper and Copper Alloy Analysis Method Photoelectric Emission Spectroscopy Standard and GB / T 5121-2008 Copper and Copper Alloy Chemical Analysis Method Determination of the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com