Preparation method of real-time vulcanized elastomer fiber membrane

A technology for vulcanizing elastomers and elastomer fibers, which is applied in the field of real-time vulcanization of elastomer fiber membranes. It can solve the problems of discontinuous conduction, metal particles are easy to fall off, and poor durability, so as to reduce stuffy discomfort and good cycle stability. and durability, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

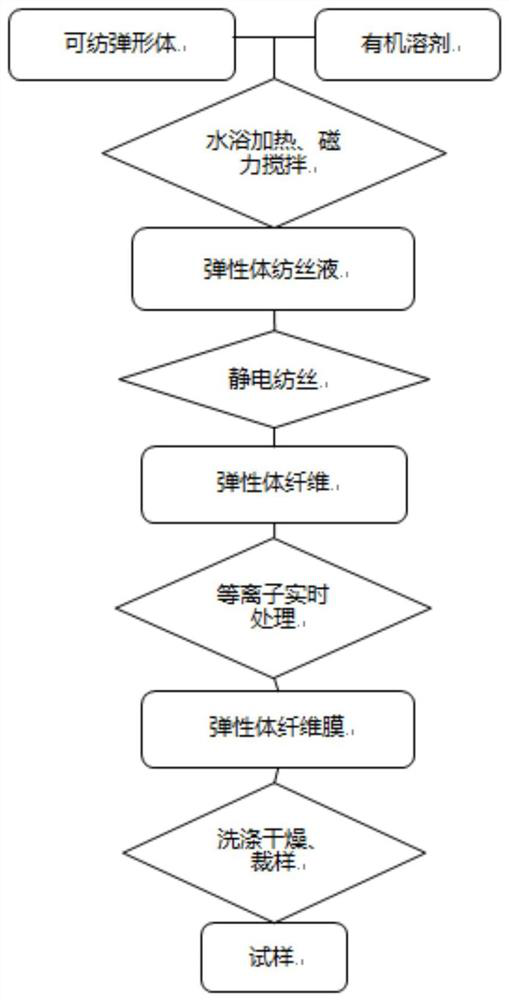

[0032] The specific process of the preparation method of the real-time vulcanized elastomer fiber film involved in the present embodiment is:

[0033] (1) Preparation of elastomer spinning solution: Dissolve trans-1,4-polyisoprene (TPI) in tetrahydrofuran, add functional fillers, heat in a water bath at a temperature of 60°C, stir magnetically for 4h, A uniformly dispersed elastomer spinning solution with a mass percentage concentration of 2% is prepared, and is used for later use;

[0034] (2) Preparation of elastomer fibers: The elastomer spinning solution is kept at a constant temperature, and through the action of an electric field, through electrospinning technology, referring to electrospinning molding equipment, a flask, a high-voltage power supply, a high-speed receiving roller, a peristaltic pump, The glove box, infrared heating lamps and spinning nozzles are used for spinning, and the jet is evaporated to obtain solid elastomer fibers. The nozzle needle is 20G, the ...

Embodiment 2

[0038]The process of the preparation method of the real-time vulcanized elastomer fiber film involved in this embodiment is as follows: fully dissolving the white granular TPI and the vulcanization system in a mixed organic solvent composed of tetrahydrofuran and N,N-dimethylformamide, Turn on the infrared heating lamp in the glove box, control the ambient temperature, and use electric field spinning to obtain TPI elastomer fibers. The plasma nozzle is placed 10 cm from the non-collecting side of the high-speed collecting roller. While the high-speed collecting roller collects the TPI elastomer fibers, The plasma equipment processes the elastomer fibers in real time, and obtains a uniform plasma real-time vulcanized TPI elastomer fiber film.

Embodiment 3

[0040] The specific process of the preparation method of the real-time vulcanized elastomer fiber film involved in the present embodiment is:

[0041] Fully dissolve TPI-40 with a density of ≥ 0.940 produced by Qingdao Junxiang Technology Co., Ltd. in analytically pure tetrahydrofuran and dimethylformamide, and add functional fillers composed of insoluble sulfur, TMTD, CZ, RD and 4010 to prepare Elastomer spinning solution;

[0042] The elastomer spinning solution is kept at a constant temperature of 40 °C, and is spun under the action of an electric field, and the jet is evaporated to obtain solid elastomer fibers;

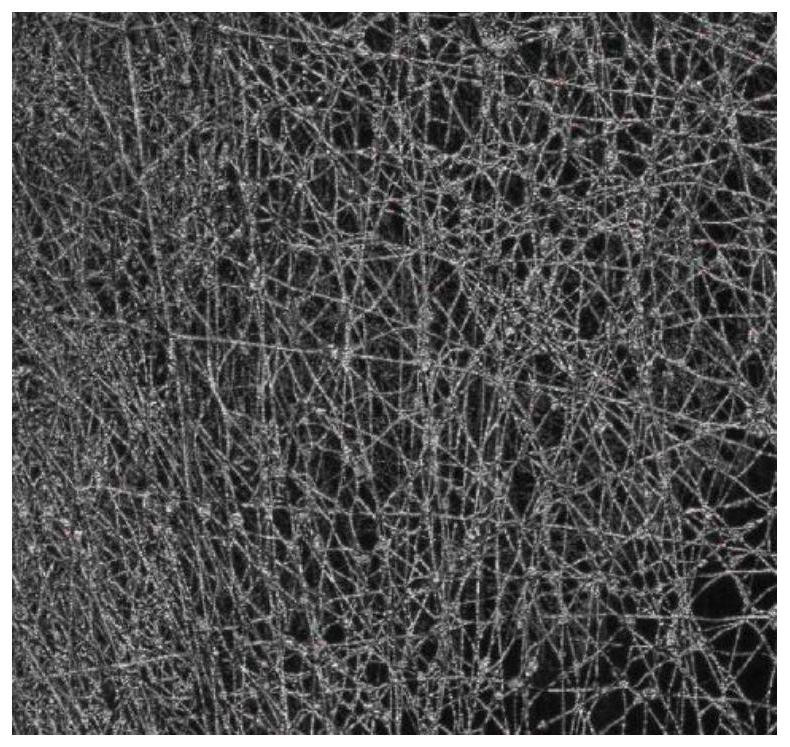

[0043] The elastomer fibers were collected, and the vulcanized elastomer fibers were treated with plasma equipment at the same time. The air pressure of the plasma real-time vulcanization gas source was 6 bar. After ventilation, the elastomer fibers were removed, rinsed with deionized water, and dried at room temperature to obtain an elastomer fiber film.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com