Preparation method of CoP-coated Co2P nanosheet catalyst for synthesizing amylamine from valeronitrile

A technology of nanosheets and catalysts, applied in the field of preparation of CoP@Co2P nanosheet catalysts for the synthesis of pentylamine from valeronitrile, which can solve the problems of high pressure, many by-products, and low product yields, so as to reduce the reaction temperature and improve hydrogenation Activity, the effect of good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

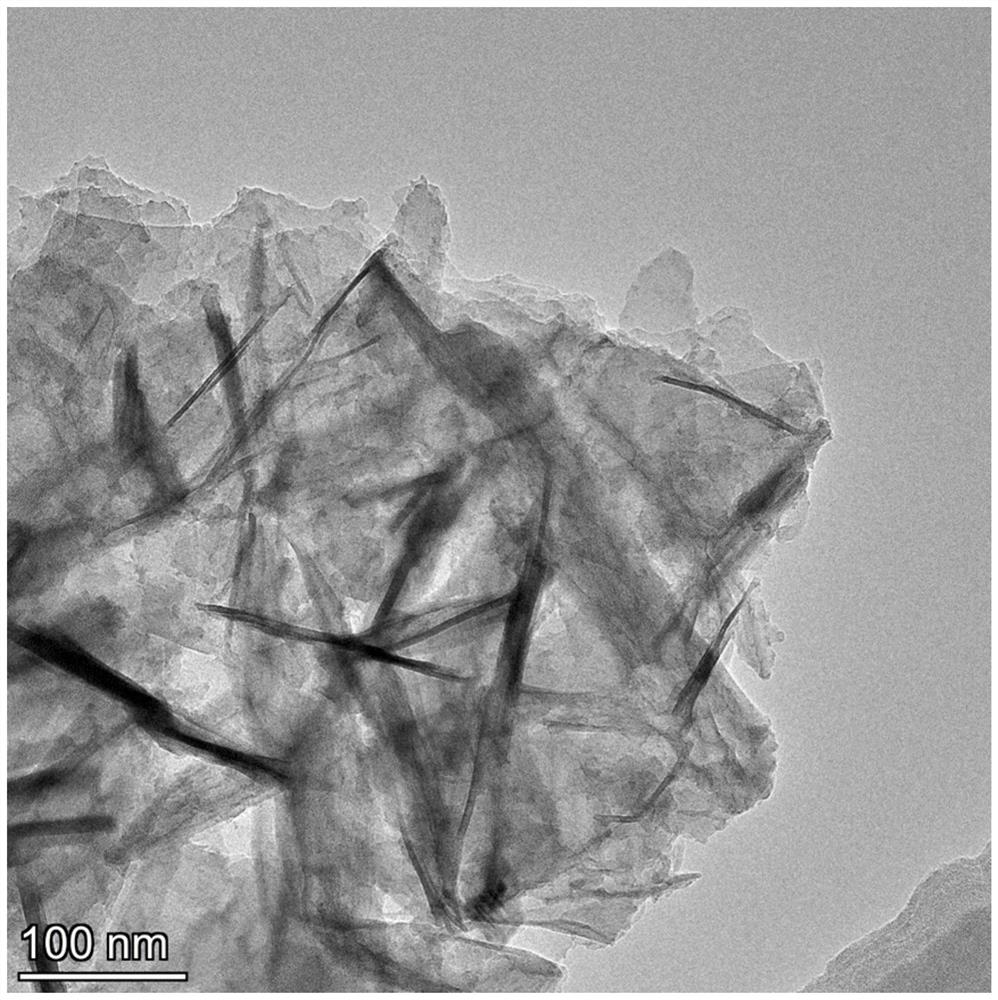

Image

Examples

Embodiment 1

[0026] The process of preparing catalysts

[0027] Weigh 5g of cobalt acetate, dissolve it in 150g of ethanol, and then add 0.01mol / L of ammonia 10g dropwise, stir and transfer to the hydrothermal synthesis kettle, 140 °C water heat 4.5h, filter drying to obtain Co 3 O 4 。 Take 1 g of the Co prepared above 3 O 4, with 5g LiCl and 3g sodium hypophosphite placed in a mortar grinding, and then transferred to the quartz boat, placed in a tube furnace, roasted at 250 ° C for 4.0h, and then washed and dried to obtain CoP@Co 2 P nanosheet catalyst, closed preservation.

[0028] Hydrogenation reaction process

[0029] Take the above prepared catalyst 0.1g in a round bottom flask, through the nitrogen for replacement, and then 1.0 g of pentylenitrile and 0.8 g of aminoborane solution into the round bottom flask, stirring, heating to 70 °C reaction, after the end of the reaction to remove the catalyst to obtain the target product penylamine.

[0030] The conversion rate of pentylene nitrile...

Embodiment 2

[0032] The process of preparing catalysts

[0033] Weigh 5g cobalt acetate, dissolve it in 225g ethanol, and then add a certain 0.05mol / L ammonia 5g dropwise, stir and transfer to the hydrothermal synthesis kettle, 160 °C water heat 2.5h, filter drying to obtain Co 3 O 4 。 Take 1 g of the Co prepared above 3 O 4 With 1gLiCl and 2g sodium hypophosphite placed in a mortar grinding, then transferred to a quartz boat, placed in a tubular furnace, roasted at 400 ° C for 2.0h, and then washed and dried to obtain CoP@Co 2 P nanosheet catalyst, closed preservation.

[0034] Hydrogenation reaction process

[0035] Take the above prepared catalyst 0.1g in a round bottom flask, through the nitrogen for displacement, and then 1.4 g of pentylenitrile and 1.5 g of aminoborane solution into the round bottom flask, stirring, heating to 90 °C reaction, after the end of the reaction to remove the catalyst to obtain the target product penylamine.

[0036]The conversion rate of pentylene nitrile was ...

Embodiment 3

[0038] The process of preparing catalysts

[0039] Weigh 5g cobalt acetate, dissolve it in 175g ethanol, and then add a certain 0.04mol / L ammonia water 6g dropwise, stir and transfer to the hydrothermal synthesis kettle, 150 °C water heat 3.5h, filter drying to obtain Co 3 O 4 。 Take 1 g of the Co prepared above 3 O 4 With 3gLiCl and 2.5g sodium hypophosphite placed in a mortar grinding, then transferred to a quartz boat, placed in a tubular furnace, roasted at 300 ° C for 3.0h, and then washed and dried to obtain CoP@Co 2 P nanosheet catalyst, closed preservation.

[0040] Hydrogenation reaction process

[0041] Take the above prepared catalyst 0.1g in a round bottom flask, through the nitrogen for replacement, and then 1.2 g of pentylenitrile and 1.3 g of aminoborane solution into the round bottom flask, stirring, heating to 80 °C reaction, after the end of the reaction to remove the catalyst to obtain the target product penylamine.

[0042] The conversion rate of pentylene nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com