Online high-space and time-resolved extreme ultraviolet radiation damage pumping-detection system

A time-resolved, radiation-damaged technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of limited machine time, bulky, expensive construction, etc., to improve the imaging signal-to-noise ratio, high energy stability, high The effect of positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

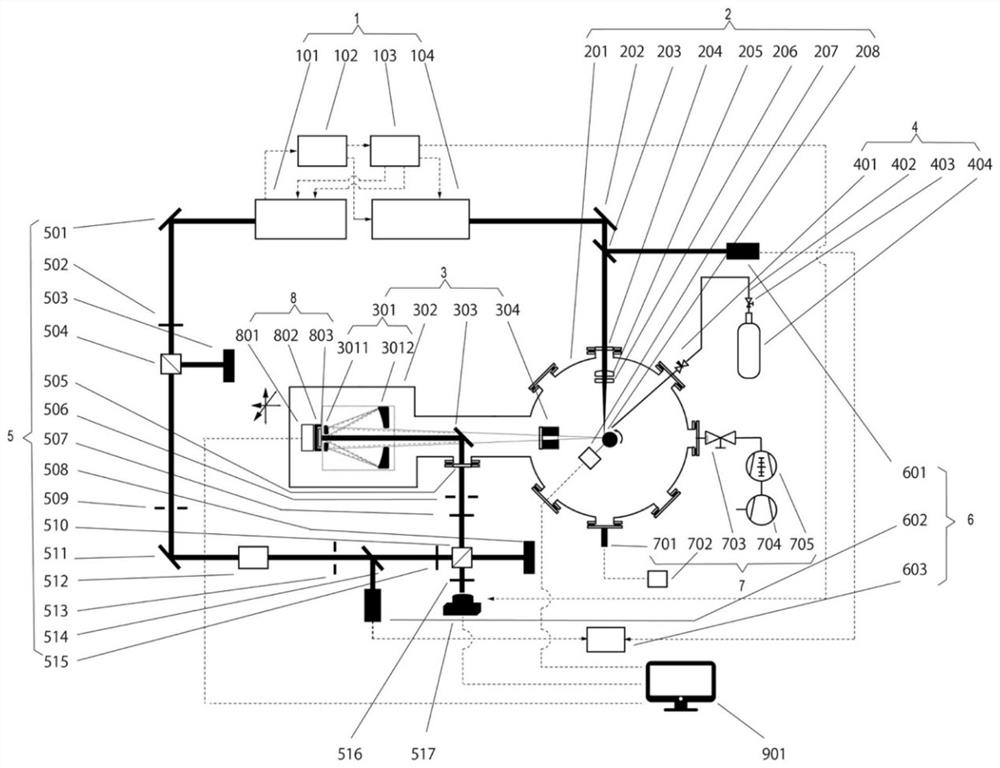

[0035] like figure 1 As shown, this embodiment provides an online high spatial and temporal resolution EUV radiation damage pump-detection system, which can be conveniently placed on a laboratory optical platform for experiments, including a laser light source assembly 1, a laser plasma light source assembly 2. The EUV nanosecond pumping optical circuit assembly 3, the infrared femtosecond detection imaging optical circuit assembly 5 and the laser time delay detection assembly 6, the laser plasma light source assembly 2 and the EUV nanosecond pumping optical circuit assembly 3 are formed for placing the sample 803 The vacuum cavity, wherein the laser light source assembly 1 includes an infrared femtosecond laser 101 and an infrared nanosecond laser 104, and the infrared femtosecond laser 101 and the infrared nanosecond laser 104 generate infrared femtosecond detection laser and infrared nanosecond based on the set timing control The pump light and the infrared nanosecond pump ...

Embodiment 2

[0056] On the basis of Embodiment 1, the EUV nanosecond pump light energy attenuation component 4 is used to change the EUV nanosecond pump light energy in this embodiment, and the EUV nanosecond pump light energy attenuation component 4 includes needles connected in sequence. The valve 401, the capillary tube 402, the pressure reducing valve 403, the gas cylinder 404, and the needle valve 401 are connected to the vacuum chamber.

[0057] Further, in this embodiment, the vacuum assembly 7 is used to measure and adjust the degree of vacuum through the vacuum assembly 7. The vacuum assembly 7 includes a vacuum gauge 701, a vacuum gauge 702, a hand valve 703, a mechanical pump 704 and a molecular pump 705, and the vacuum gauge 701 and the hand valve 705. The valves 703 are all connected to the vacuum chamber, the vacuum gauge 702 is connected to the vacuum gauge 701 , the mechanical pump 704 , the molecular pump 705 and the hand valve 703 are connected in sequence, and the pumping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com