Bimetal supported catalyst, preparation method thereof and application of bimetal supported catalyst in preparation of biological aviation kerosene through hydrogenation conversion of palm oil

A technology of supported catalysts and aviation kerosene, which is applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc. It can solve the problems of high cost, high price, and poor stability of precious metals, and achieve green and simple preparation processes and promising application prospects Good, synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

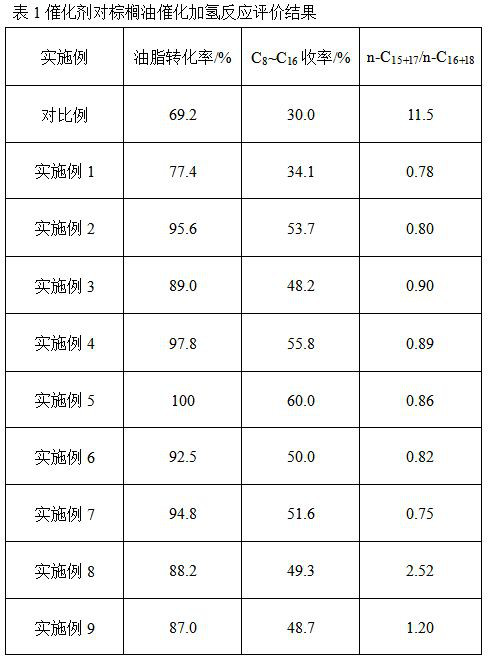

Examples

Embodiment 1

[0032] Dissolve 0.009 mol of nickel chloride hexahydrate and 0.001 mol of ferric chloride hexahydrate in 100 mL of deionized water with common stirring to form solution A, then add 5.3 g of Beta molecular sieve powder to solution A, and stir at a certain speed to form a solution. Suspension B. Then prepare 0.05mol / L NaOH alkaline solution C, add it dropwise to suspension B under the stirring speed of 800 rpm and 30 °C water bath, adjust the pH to 8.5, and let stand for aging after 6 h in water bath. After the solid was ground into powder, it was calcined in a muffle furnace at 500 °C for 4 h, and reduced in a tube furnace at 600 °C for 3 h to obtain bimetallic NiFe / Beta. catalyst.

[0033] Take 50 g of palm oil feedstock oil and 3.0 g of the prepared bimetallic NiFe / Beta catalyst, put it into a high temperature and high pressure reactor, purge the air in the reactor and the pipeline with nitrogen, replace the residual nitrogen with hydrogen, and then add it to the reaction ve...

Embodiment 2

[0035] Dissolve 0.008 mol nickel chloride hexahydrate and 0.002 mol ferric chloride hexahydrate together in 100 mL deionized water with stirring to form solution A, then add 5.2 g Beta molecular sieve powder to solution A, stirring at a speed of 800 rpm , 30 ℃ water bath conditions, dropwise added it into the suspension B, adjust the pH to 8.5, after 6 h in the water bath, let stand for 6 h, filter and wash to neutrality, dry at 80 ℃ for 8 h, After the solid was ground into powder, it was calcined in a muffle furnace at 500 °C for 4 h, and reduced in a tube furnace at 600 °C for 3 h to obtain a single-metal NiFe / Beta catalyst.

[0036] Take 50 g of palm oil feedstock oil and 3.0 g of the prepared bimetallic NiFe / Beta catalyst, put it into a high temperature and high pressure reactor, purge the air in the reactor and the pipeline with nitrogen, replace the residual nitrogen with hydrogen, and then add it to the reaction vessel. The kettle was filled with ordinary hydrogen to ca...

Embodiment 3

[0038] Dissolve 0.007 mol nickel chloride hexahydrate and 0.003 mol ferric chloride hexahydrate in 100 mL of deionized water with stirring together to form solution A, then add 5.2 g Beta molecular sieve powder to solution A, stirring at a speed of 800 rpm , 30 ℃ water bath conditions, dropwise added it into the suspension B, adjust the pH to 8.5, after 6 h in the water bath, let stand for 6 h, filter and wash to neutrality, dry at 80 ℃ for 8 h, After the solid was ground into powder, it was calcined in a muffle furnace at 500 °C for 4 h, and reduced in a tube furnace at 600 °C for 3 h to obtain a single-metal NiFe / Beta catalyst.

[0039] Take 50 g of palm oil feedstock oil and 3.0 g of the prepared bimetallic NiFe / Beta catalyst, put it into a high temperature and high pressure reactor, purge the air in the reactor and the pipeline with nitrogen, replace the residual nitrogen with hydrogen, and then add it to the reaction vessel. The kettle was filled with ordinary hydrogen to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com