Preparation method and application of bismuth oxychloride photocatalyst

A bismuth oxychloride and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of complex preparation process, difficulty in batch production and application, high energy consumption, etc., and achieve the effect of green and simple preparation process, mass production and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

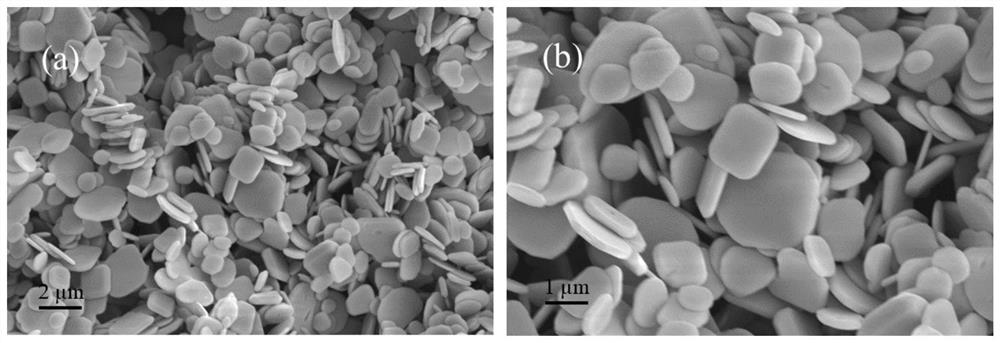

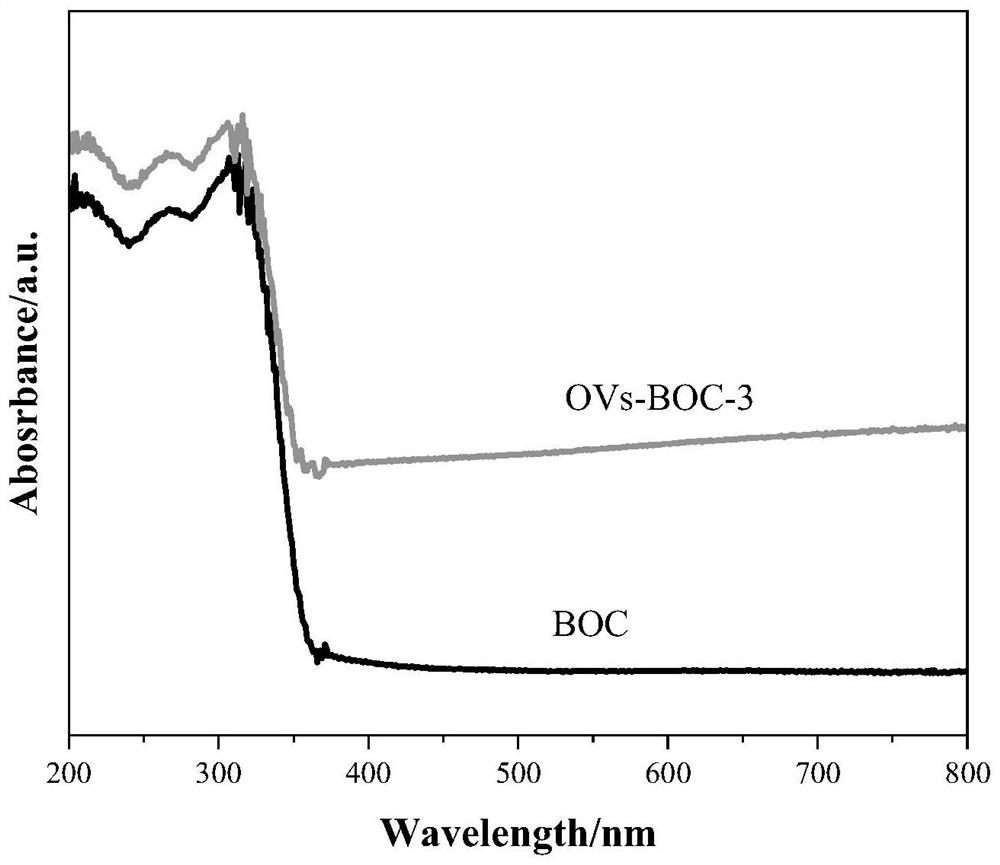

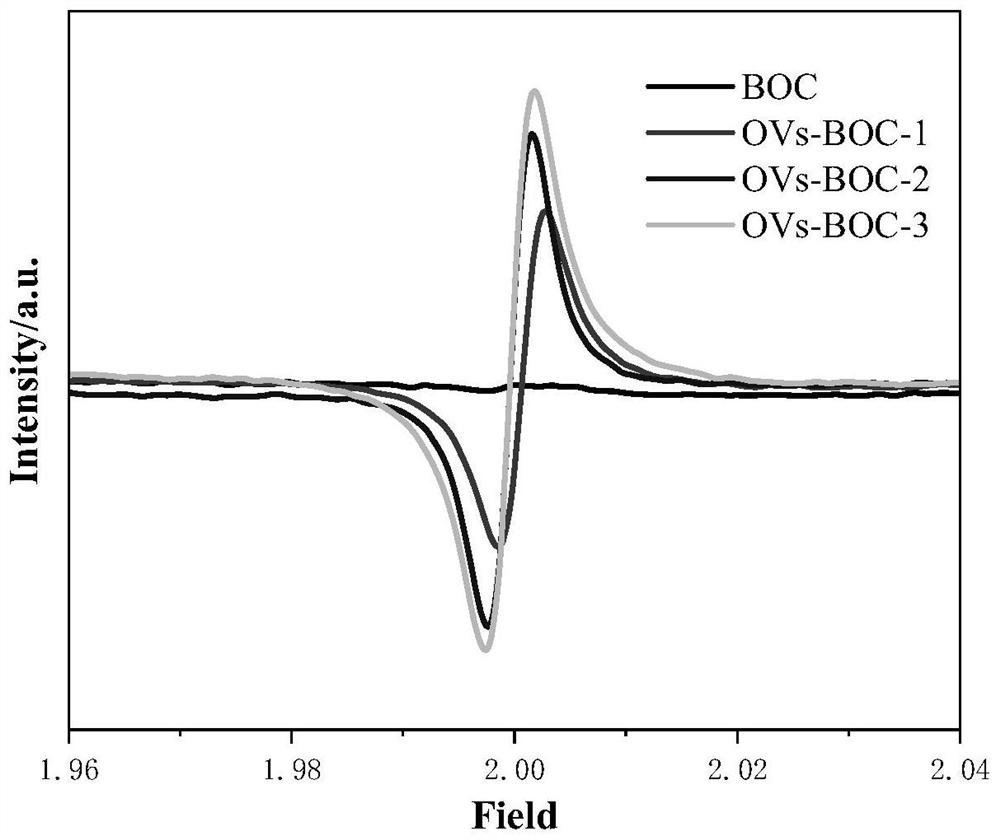

[0029] A method for preparing a bismuth oxychloride photocatalyst according to an embodiment of the present invention includes the following steps: weighing 4 mmol of bismuth nitrate pentahydrate and 4 mmol of sodium chloride in a beaker, adding 80 mL of deionized water, and fully stirring at room temperature for 20 min; The mixed solution was transferred to a 100 mL polytetrafluoroethylene reactor for thermal reaction, and the reaction conditions were 150 °C for 12 h; after the reaction was completed, it was cooled to room temperature for suction filtration; after suction filtration, the filter residue was washed three times with ethanol and deionized water, respectively, and the sample Place at 60°C and dry for 12h to obtain bismuth oxychloride powder; irradiate the obtained bismuth oxychloride powder under a 6W UV lamp for 2h to obtain a bismuth oxychloride photocatalyst with surface defects, denoted as OVs-BOC-1.

Embodiment 2

[0031] A method for preparing a bismuth oxychloride photocatalyst according to an embodiment of the present invention includes the following steps: weighing 4 mmol of bismuth nitrate pentahydrate and 4 mmol of sodium chloride in a beaker, adding 80 mL of deionized water, and fully stirring at room temperature for 20 min; The mixed solution was transferred to a 100 mL polytetrafluoroethylene reaction kettle for thermal reaction, and the reaction conditions were 150 °C for 12 h; after the reaction was completed, it was cooled to room temperature for suction filtration; Dry at 60°C for 12 hours to obtain bismuth oxychloride powder; irradiate the obtained bismuth oxychloride powder under a 6W UV lamp for 4 hours to obtain a bismuth oxychloride photocatalyst with surface defects, denoted as OVs-BOC-2.

Embodiment 3

[0033] A method for preparing a bismuth oxychloride photocatalyst according to an embodiment of the present invention includes the following steps: weighing 4 mmol of bismuth nitrate pentahydrate and 4 mmol of sodium chloride in a beaker, adding 80 mL of deionized water, and fully stirring at room temperature for 20 min; The mixed solution was transferred to a 100 mL polytetrafluoroethylene reaction kettle for thermal reaction, and the reaction conditions were 150 °C for 12 h; after the reaction was completed, it was cooled to room temperature for suction filtration; Dry at 60°C for 12 hours to obtain bismuth oxychloride powder; irradiate the obtained bismuth oxychloride powder under a 6W UV lamp for 6 hours to obtain a bismuth oxychloride photocatalyst with surface defects, which is denoted as OVs-BOC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com