A kind of heterojunction MOF catalyst and its preparation method and application

A heterojunction and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem that photocatalytic performance has not received much attention, MOFs poor stability and other issues, to achieve excellent photocatalytic performance, good stability, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Heterojunction MOF photocatalyst [Fe-(2-mim) / H 2 The preparation method of BDC], the steps are as follows:

[0048] (1) Dissolve 40mmol 2-methylimidazole in 25mL N,N-dimethylformamide, stir until completely dissolved to obtain reaction solution A; dissolve 4mmol terephthalic acid in 25mL N,N-dimethylformamide Amide, stirred until completely dissolved to obtain reaction solution B; 4mmol FeCl 3 Dissolve in 50mL N,N-dimethylformamide and stir until completely dissolved to obtain reaction solution C.

[0049] (2) Mix the reaction solution A with the reaction solution B, and stir evenly to obtain the reaction solution D; add the reaction solution D dropwise to the reaction solution C to obtain a uniform heterojunction MOF precursor solution;

[0050] (3) Transfer the homogeneous heterojunction MOF precursor solution to a high-pressure reactor, conduct a hydrothermal reaction at 150°C for 15 hours, centrifuge, wash with ethanol and distilled water in turn, and carry out th...

Embodiment 2

[0053] The mixed organic ligands form a heterojunction during the preparation process, which can improve the stability and degradation effect of the prepared MOFs after being combined with the central metal atom. The photocatalytic effect of the heterojunction MOF is better than that of any single organic ligand and The prepared MOFs are combined with the same central metal atoms.

[0054] Taking the degradation of Cr(VI)-containing wastewater as an example to compare the photocatalytic activity. Add chromium-containing wastewater with a volume of 100 mL and a concentration of 80 μmol / L into the reactor, add 10 mg of different organic ligand MOFs visible light catalysts, do not adjust the pH, keep stirring, stir in the dark for 30 minutes to adsorption equilibrium, and turn on the visible light source , sampling at intervals of 15 minutes.

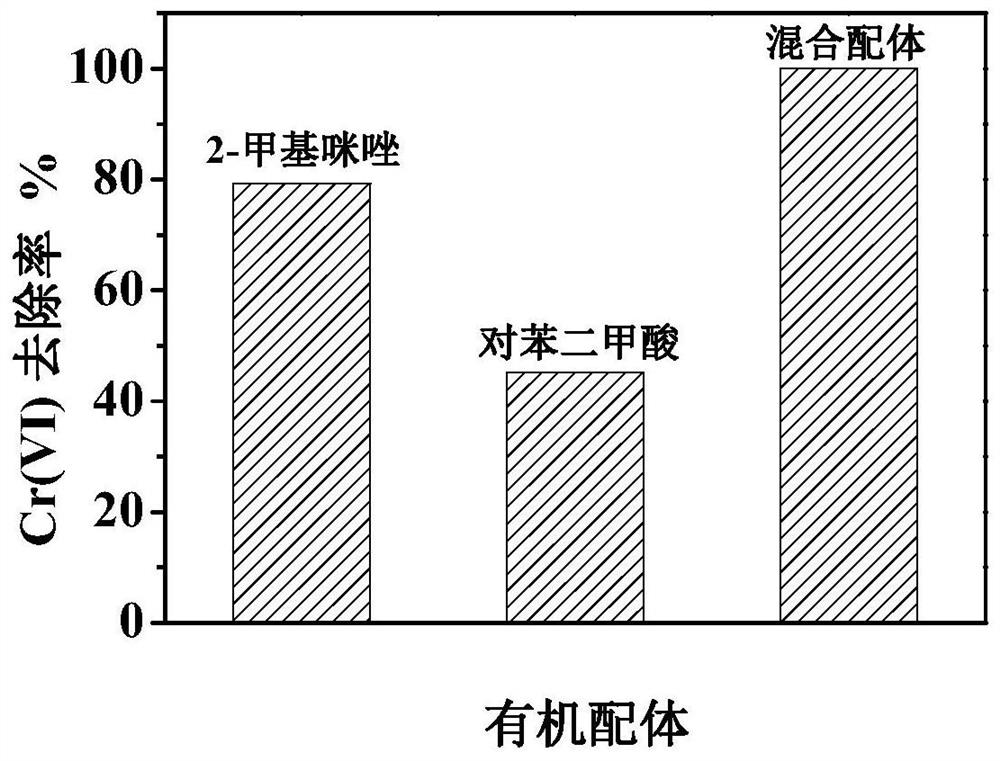

[0055] Such as figure 1 , the visible-light photocatalytic activity of the heterojunction MOF is significantly better than that of any ...

Embodiment 3

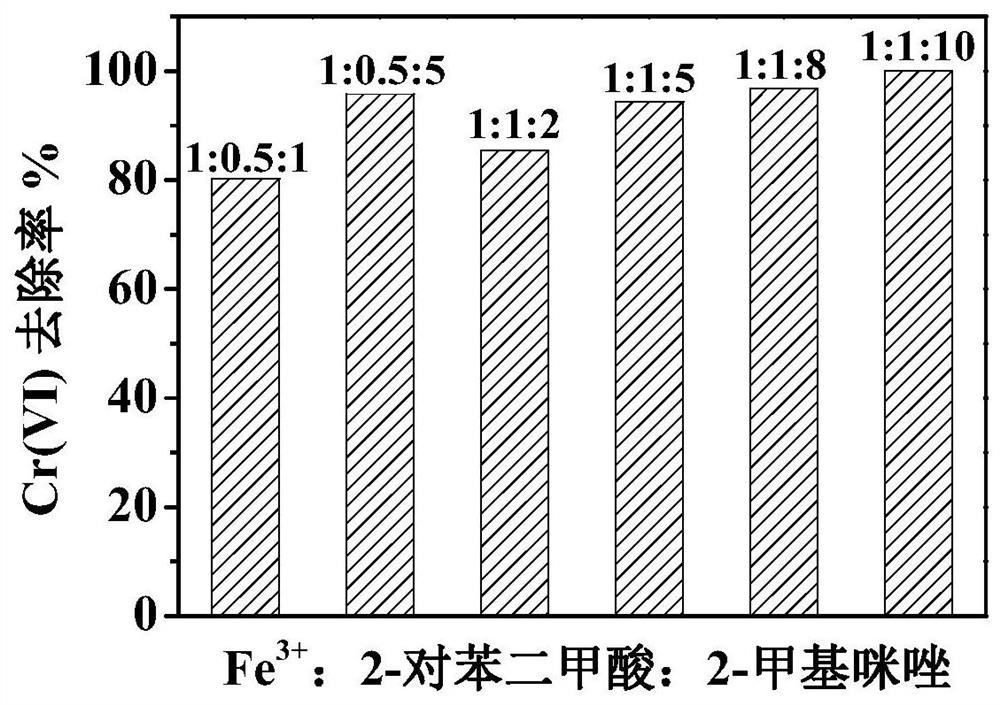

[0057] Two kinds of organic ligands are mixed with the central metal atoms to prepare heterojunction MOFs. Changing the mixing ratio of the organic ligands will lead to changes in the binding mode and order of the central metal atoms, resulting in changes in the microstructure of the prepared heterojunction MOFs, and then Affecting the visible light catalytic effect of heterojunction MOFs.

[0058] A series of catalysts were prepared by changing the mixing ratio of 2-methylimidazole and terephthalic acid in Example 1, and compared with the chromium reduction operation in Example 2.

[0059] Such as figure 2 , in 2-methylimidazole with terephthalic acid and Fe 3+ When the molar ratio of Cr(VI) is 10:1:1, the reduction effect of Cr(VI) is the best, so the heterojunction MOF prepared under this ratio has the best visible light catalytic activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com